A kind of defoaming method of insulating resin material

A technology of insulating resin and resin material, applied in the field of defoaming of insulating resin material, can solve the problems of inability to remove air bubbles, harsh environmental requirements, etc., and achieve the effect of eliminating defective pores, improving protection quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objects, technical solutions, and advantages of the present invention more clearly, the technical solutions in the embodiments of the present invention will be described in connection with the embodiment of the present invention, and will be described in connection with the embodiment of the present invention. Embodiments, not all of the embodiments. Based on the embodiments in the present invention, all other embodiments obtained without creative labor are not made in the premise of creative labor.

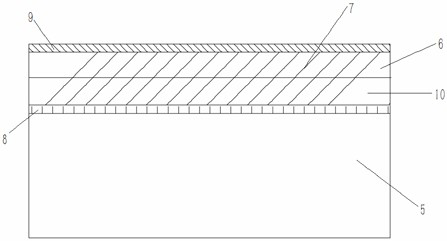

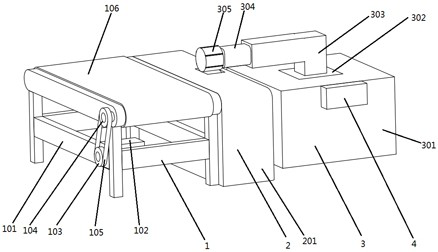

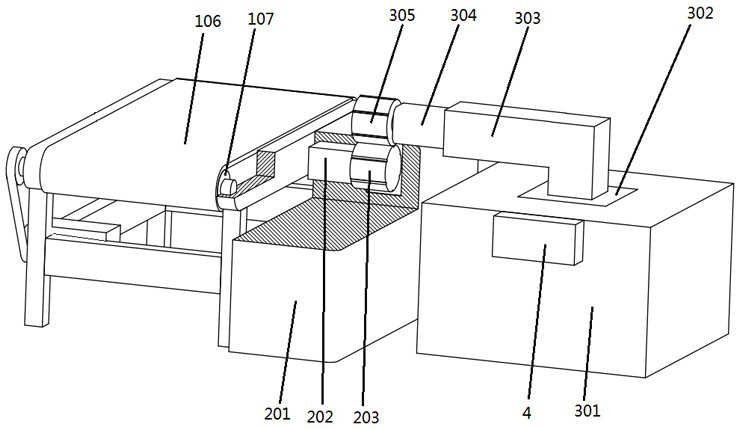

[0032] According to the dismantling analysis of the direct drive permanent magnet power generator, the failure of the rotor magnetic steel accounted for about 30% of the fault probability of generator, mainly due to the pores of the magnetic pole protector. During the operation of the wind turbine, the gas-guided steel is gradually become the weakness of magnetic steel anti-corrosion, which will cause magnetic steel anti-corrosion, causing the generator fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com