Anti-hardening pulse dust remover

A pulse dust collector and anti-hardening technology, which is applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of machine working time and impact on the life of dust filter bags, and reduce the probability of dust compaction , The effect of reducing the probability of sticking to the dust filter bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

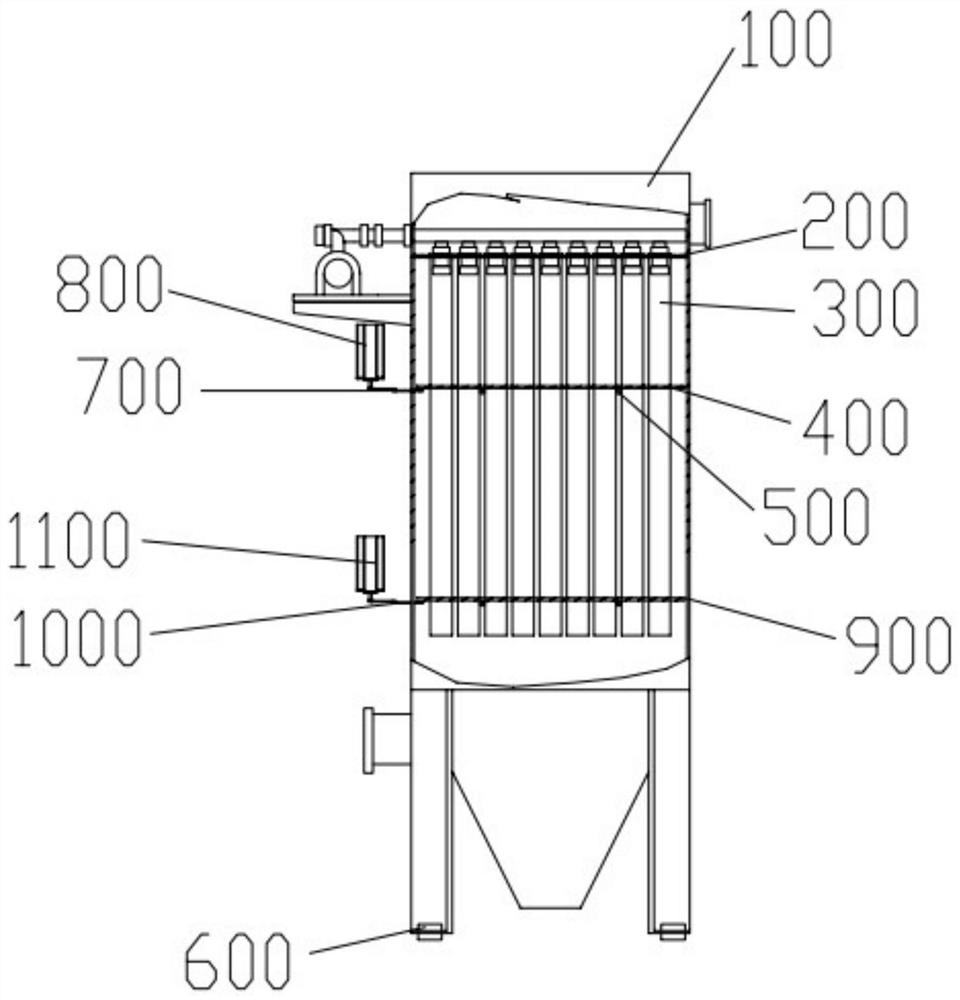

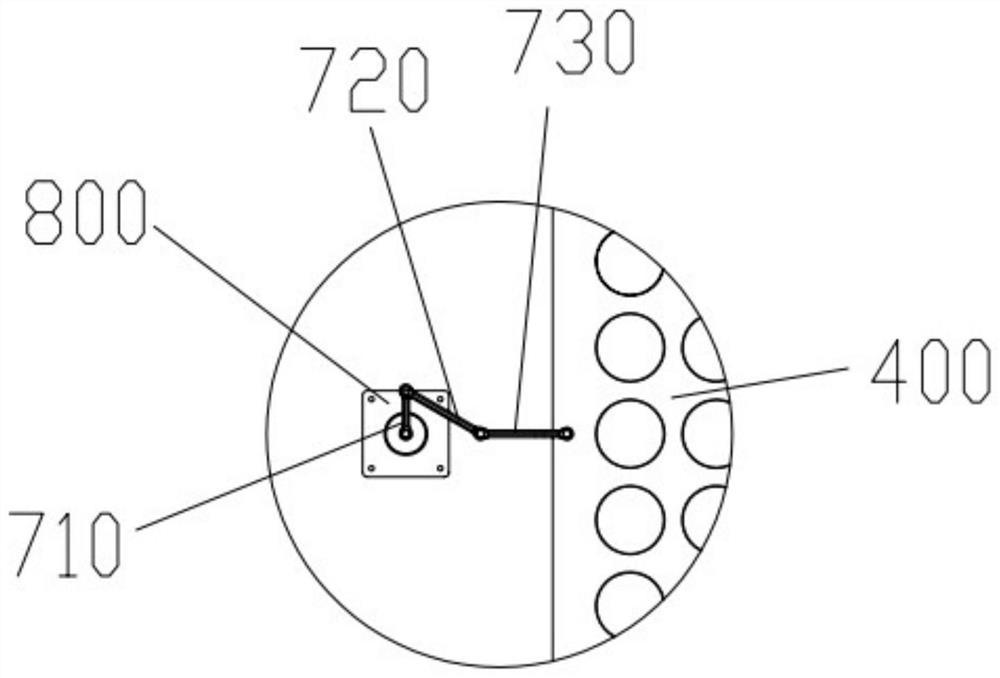

[0023] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention. The present invention is described in detail by using structural schematic diagrams, etc., and the schematic diagrams are only examples, which should not limit the protection scope of the present invention. In addition, the three-dimensional space of length, width and depth should be included in actual production.

[0024] An anti-hardening pulse dust collector, including a dust removal box. There are several brackets under the dust removal box. The brackets are fixed on the ground by bolts. A flower plate is arranged in the dust removal box, and a number of dust filter bags are hung on the flower plate. The dust removal box is provided with a vibrating device....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com