Polyamide composition suitable for liquid assisted molding and preparation method thereof

A polyamide composition and auxiliary molding technology, applied in the field of polymer materials, can solve the problems of deterioration of weather resistance, unsatisfactory performance of improving appearance and improving fluidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

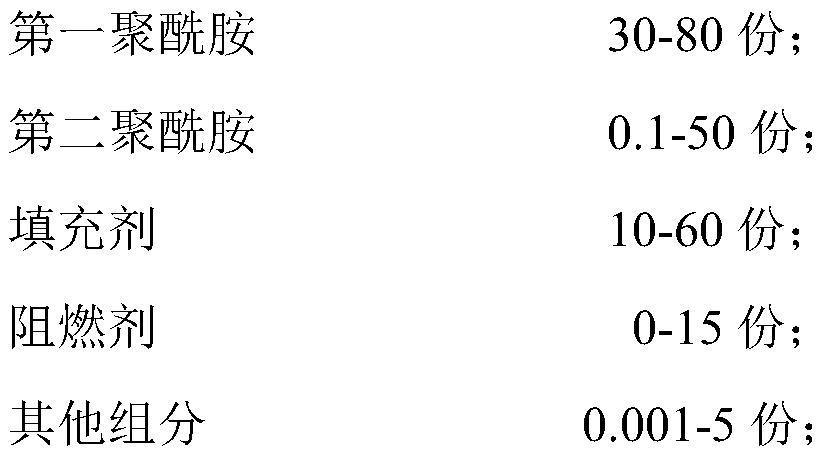

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

[0054] Each raw material used in the embodiment and comparative example of table 1 is as follows:

[0055] Grade supplier PA6 M2400 Guangdong Xinhui Meida PA66 / 6 EP158 Zhejiang Huafeng PA56 self made / PAD6 self made / PA6I6T Selar PA3426 dupont antioxidant Antioxidant 1098 BASF Processing Antioxidant PEP-36 ADK lubricant A-C540A Honeywell H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com