Automatic climbing device for scaffold

A scaffolding and automatic technology, which is applied to the accessories of the scaffolding, the scaffolding supported by the building structure, the support of the building structure, etc. rods etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

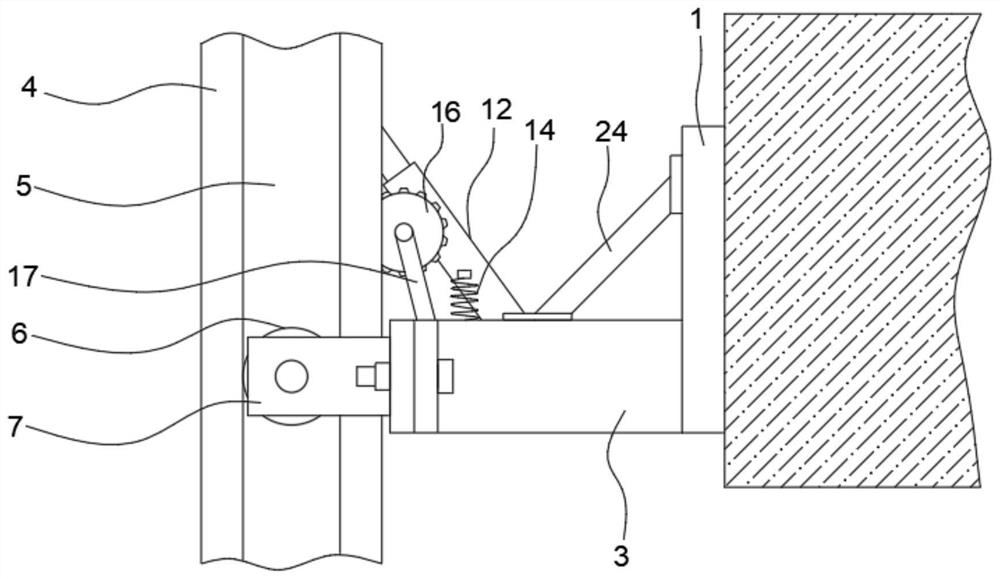

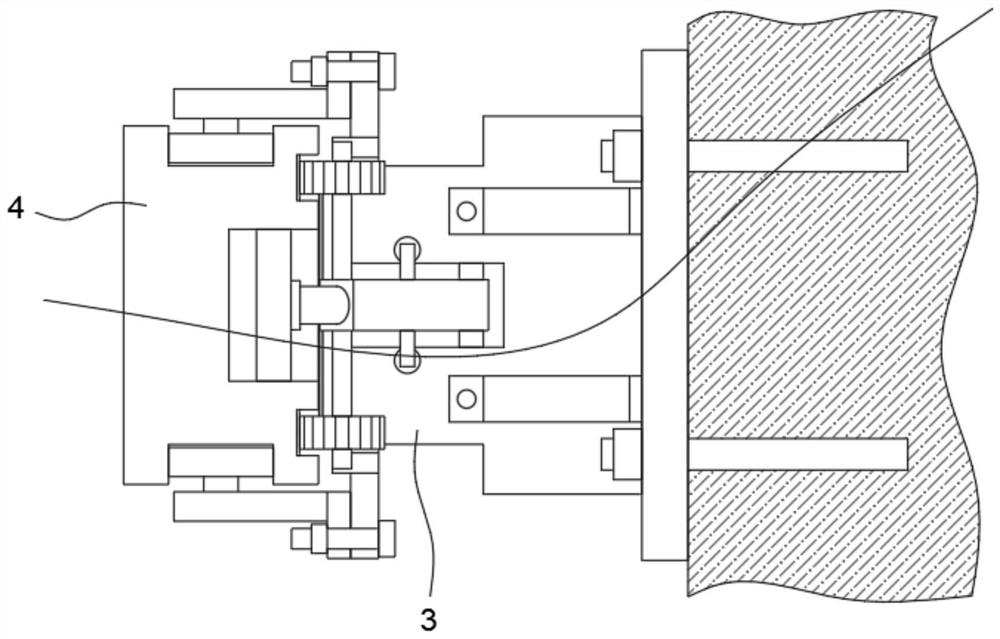

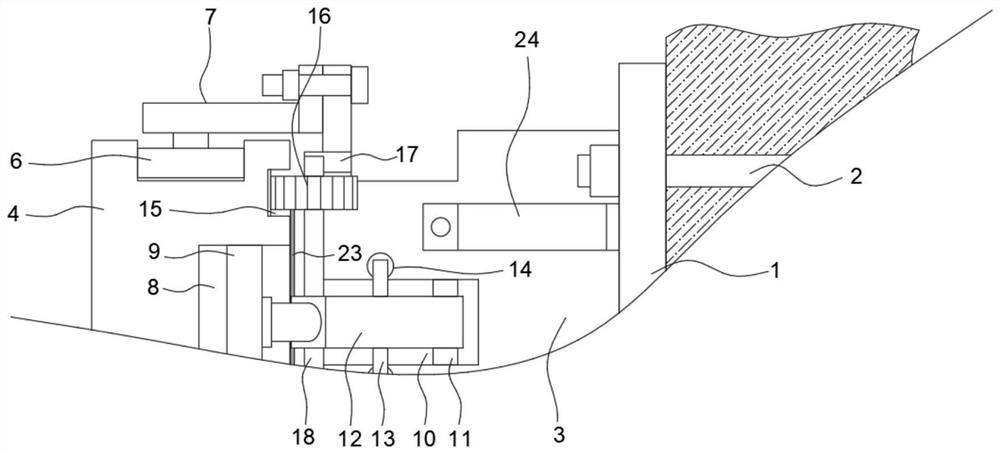

[0022] refer to Figure 1-5 , an automatic climbing device for scaffolding, comprising an outer wall body, the rising outer wall body is vertically provided with embedded parts 2, the outer wall body is provided with a mounting plate 1 fixedly connected with the embedded parts 2, and the mounting plate 1 The lower left side is fixedly connected with a support 3 perpendicular to the mounting plate 1, and two inclined support frames 24 are fixedly connected between the mounting plate 1 and the upper surface of the support 3, the mounting plate 1, the support 3 and the support frame 24 forms a triangular structure to improve the stability of the device. The left side of the support 3 is provided with a guide rail 4, and a sliding assembly is provided between the guide rail 4 and the support 3. There are pulleys 6 slidingly connected in the groove 5, and the shaft centers of the two pulleys 6 away from the chute 5 are connected with a connecting plate 7 in rotation. To enable the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com