Computer vision structure vibration monitoring method based on motion compensation

A computer vision and motion compensation technology, applied in the testing, calculation, and elasticity testing of machine/structural components, can solve problems such as changes in monitoring results, affecting measurement accuracy, and angle changes, reducing labor costs and improving monitoring accuracy. High, simple equipment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

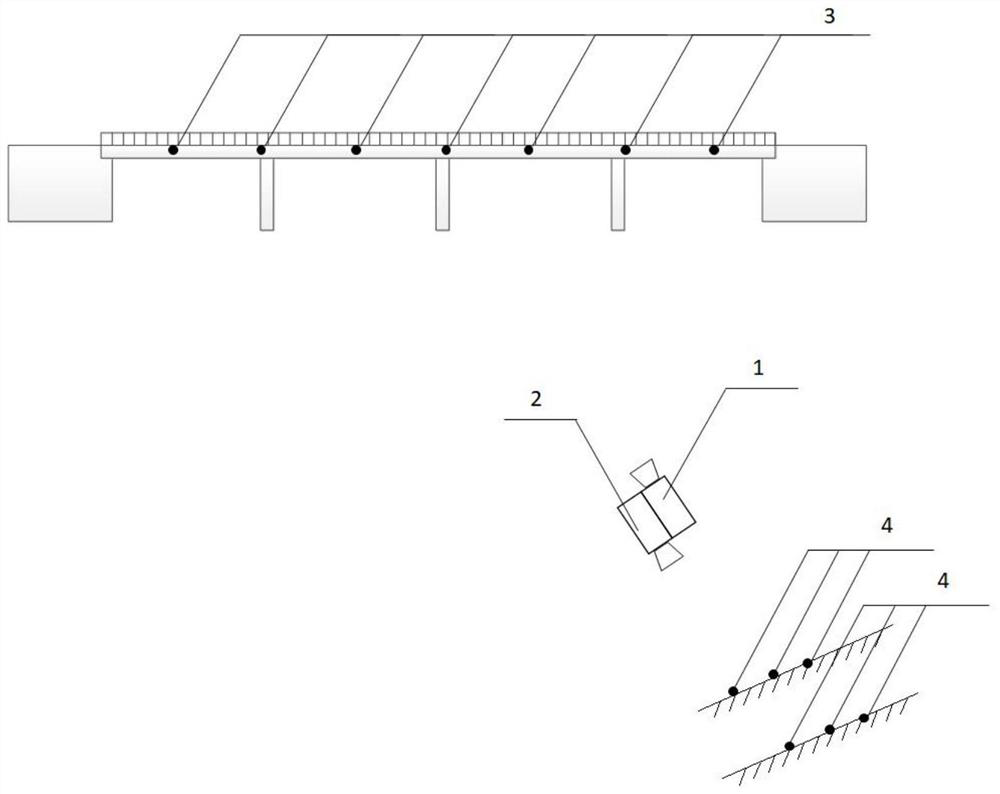

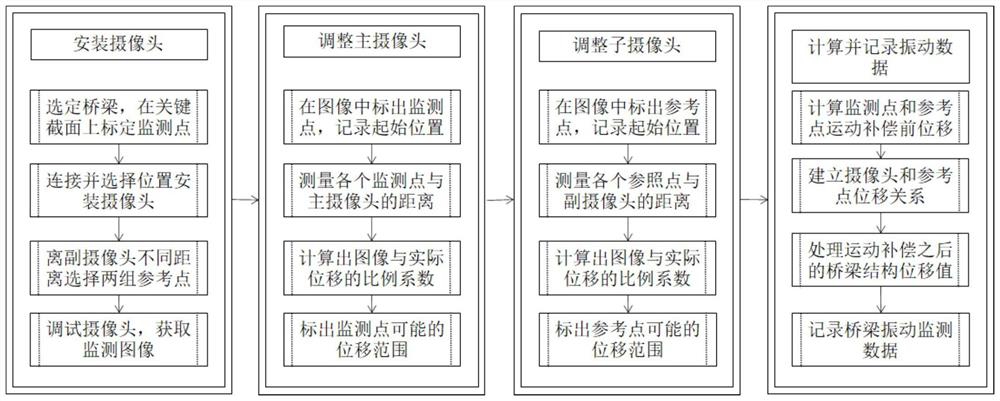

[0047] The following combination figure 1 The schematic diagram of the instrument arrangement shown in and figure 2 The implementation flow chart shown in further illustrates the specific embodiment of the present invention. The specific steps are as follows:

[0048] A computer vision structural vibration monitoring method based on motion compensation, comprising the following steps:

[0049] A install the camera;

[0050] A1. Select a number of monitoring positions in key areas such as the fulcrum of the bridge to be tested, the mid-span, and the anchor point of the cable, and select the position with obvious contour features as the monitoring point 3;

[0051] A2. Rigidly connect the main camera 1 and the sub-camera 2, select the installation location, align the main camera with the monitoring bridge, and the sub-camera with the nearby wall or ground where no displacement is assumed;

[0052]A3. On the wall or the ground within the monitoring range of the secondary cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com