Carbon layer-coated nano-manganese tetraoxide shell-core structure material and preparation method thereof

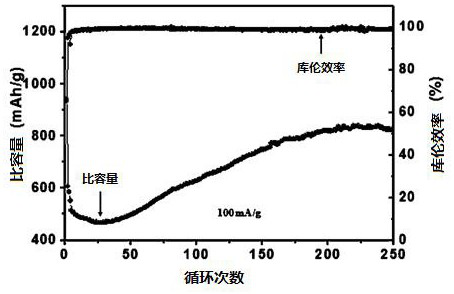

A core-shell structure and coating technology, applied in nanotechnology, structural parts, nanotechnology, etc., can solve the problems of material capacity reduction, slow electron transmission rate, low rate performance, etc., to promote dispersion and grain growth, The effect of stabilizing cyclic Coulombic efficiency and alleviating structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of nano Mn 3 o 4 The synthetic method of @C material comprises the following steps:

[0034] (1) Wash the cabbage leaves with distilled water and soak them in EtOH solution (EtOH:H 2 O=1:1), and use hydrochloric acid to adjust the pH=2~4, pretreatment for two weeks to remove the organic matter and pigment in the cabbage leaves.

[0035] (2) Take out the pretreated cabbage leaves, wash them with distilled water and dry them, then soak them in 50% Mn(NO 3 ) 2The solution prepared with a concentration of 0.05 mol / L Mn(NO 3 ) 2 72 h in aqueous solution.

[0036] (3) Take out the soaked leaves, wash them with distilled water, and dry them at room temperature.

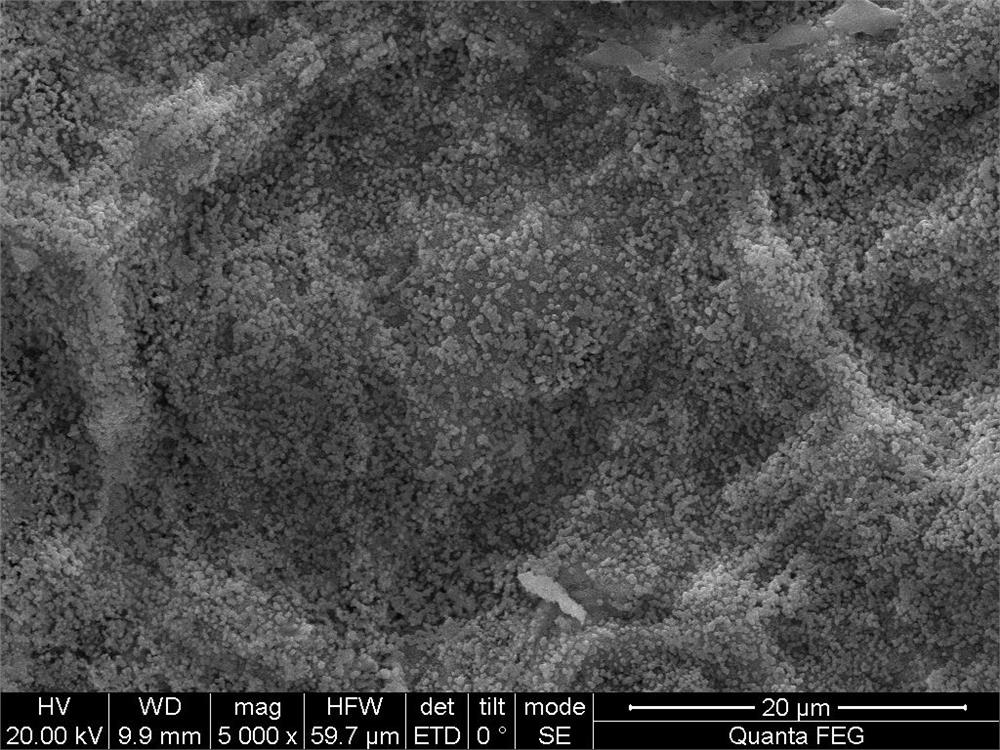

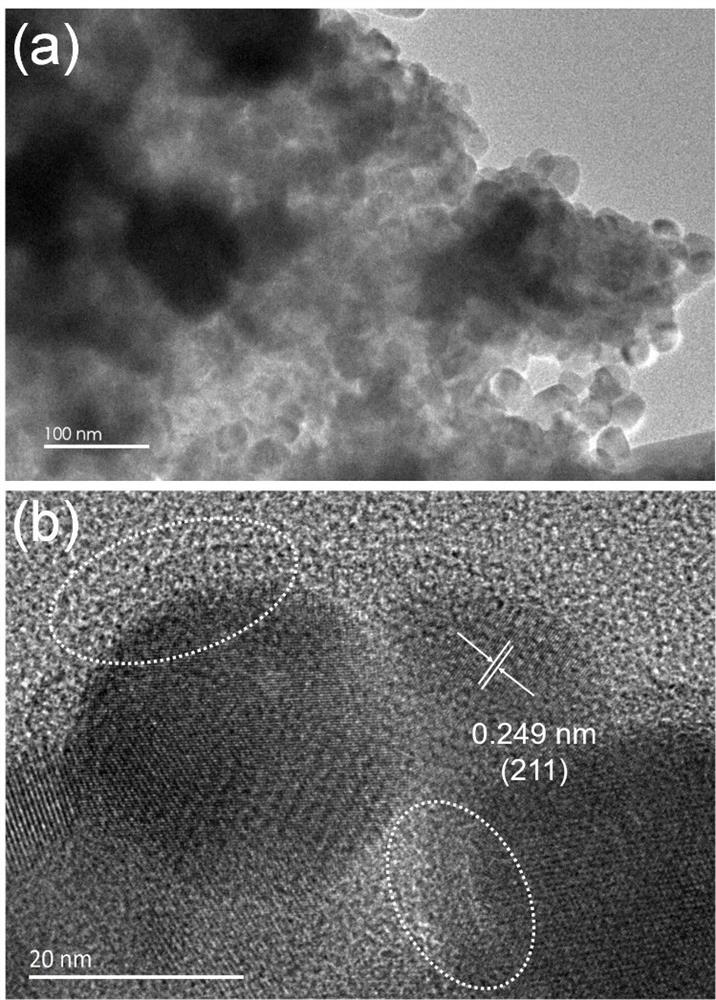

[0037] (4) Calcining the dried leaves, first in N 2 The temperature was raised to 600 °C under the atmosphere, and the heating rate was 10 °C min -1 , keep warm for 2 h, take it out and then raise the temperature to 700 °C in the air atmosphere, the heating rate is 10 °C·min -1 , and finally get the n...

Embodiment 2

[0045] (1) Wash the cabbage leaves with distilled water and soak them in EtOH solution (EtOH:H 2 O=1:1), and use hydrochloric acid to adjust the pH=2~4, pretreatment for two weeks to remove the organic matter and pigment in the cabbage leaves.

[0046] (2) Take out the pretreated cabbage leaves, wash them with distilled water and dry them, then soak them in 50% Mn(NO 3 ) 2 The concentration of solution preparation is 0.10mol / L Mn(NO 3 ) 2 72 h in aqueous solution.

[0047] (3) Take out the soaked leaves, wash them with distilled water, and dry them at room temperature.

[0048] (4) Calcining the dried leaves, first in N 2 The temperature was raised to 600 °C under the atmosphere, and the heating rate was 10 °C min -1 , keep warm for 2 h, take it out and then raise the temperature to 700 °C in the air atmosphere, the heating rate is 10 °C·min -1 , and finally get the nanometer Mn 3 o 4 @C material.

Embodiment 3

[0050] (1) Wash the cabbage leaves with distilled water and soak them in EtOH solution (EtOH:H 2 O=1:1), and use hydrochloric acid to adjust the pH=2~4, pretreatment for two weeks to remove the organic matter and pigment in the cabbage leaves.

[0051] (2) Take out the pretreated cabbage leaves, wash them with distilled water and dry them, then soak them in 50% Mn(NO 3 ) 2 The concentration of solution preparation is 0.15mol / L Mn(NO 3 ) 2 72 h in aqueous solution.

[0052] (3) Take out the soaked leaves, wash them with distilled water, and dry them at room temperature.

[0053] (4) Calcining the dried leaves, first in N 2 The temperature was raised to 600 °C under the atmosphere, and the heating rate was 10 °C min -1 , keep warm for 2 h, take it out and then raise the temperature to 700 °C in the air atmosphere, the heating rate is 10 °C·min -1 , and finally get the nanometer Mn 3 o 4 @C material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| lattice spacing | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com