Screw device

A technology of screw and screw shaft, which is applied in the direction of measuring device, transmission device, electric device, etc., and can solve problems such as peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

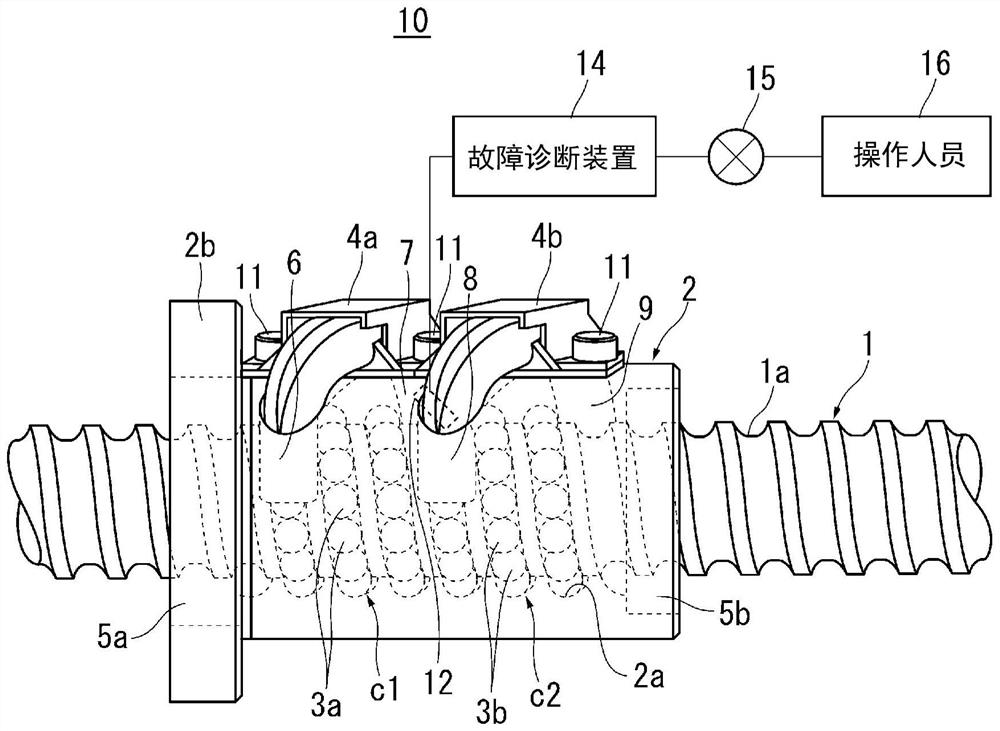

[0022] figure 1 A side view showing the screw device 10 according to the first embodiment of the present invention. 1 is a screw shaft, 2 is a nut, 3a, 3b are balls which are rolling elements interposed between them, 4a, 4b are return pipes which are circulation parts.

[0023] A helical screw groove 1 a is formed on the outer surface of the screw shaft 1 . The cross-sectional shape of the threaded groove 1a is a pointed arch. The balls 3a, 3b roll in a spiral direction on the screw groove 1a.

[0024] A nut 2 is assembled to the screw shaft 1 via balls 3 a and 3 b. The nut 2 is cylindrical. A flange 2 b for attaching the nut 2 to a target member is formed at one axial end portion of the nut 2 . A spiral screw groove 2 a facing the screw groove 1 a of the screw shaft 1 is formed on the inner surface of the nut 2 . The cross-sectional shape of the threaded groove 2a is a pointed arch. The balls 3a, 3b roll in a spiral direction on the screw groove 2a. 5 a , 5 b are seal...

no. 2 approach

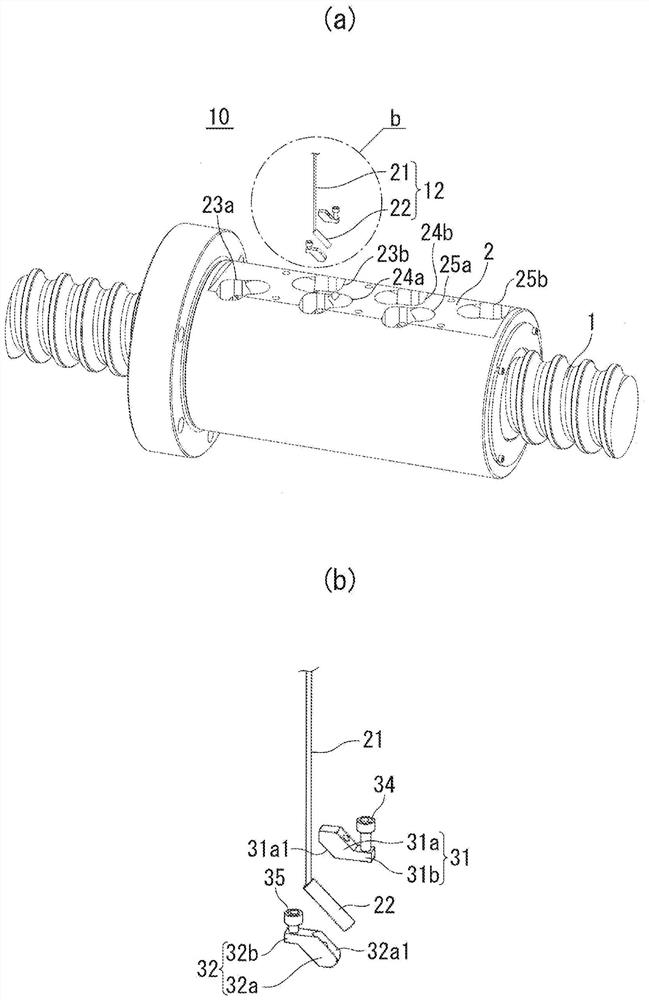

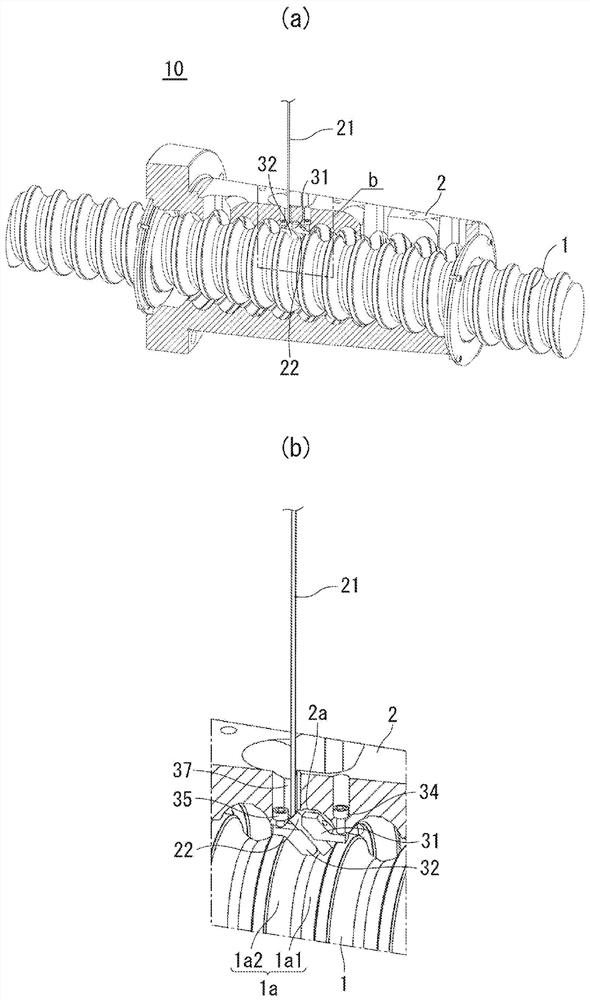

[0043] Figure 4 A side view showing a screw device according to a second embodiment of the present invention. 1 is a screw shaft, 2 is a nut, 3a, 3b are balls as rolling elements, 4a, 4b are return pipes as circulation parts, and 12 is a sensor. The configurations of the screw shaft 1 , the nut 2 , the balls 3 a and 3 b , the circulation members 4 a and 4 b , and the sensor 12 are the same as those of the first embodiment, and therefore the same reference numerals are used to omit description thereof.

[0044] In the first embodiment, the sensor 12 is sandwiched between the first holder 31 and the second holder 32 , whereas in the second embodiment, the holder 41 for holding the sensor 12 is attached to the circulation member. 4a.

[0045] Figure 5 A side view of the circulation unit 4a is shown. The holding part 41 is provided in the abdominal part (central part) of the circulation member 4a. The holding part 41 may be integrally formed with the circulation member 4a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com