Thermographic inspection of electrical equipment

A thermal imaging and imaging technology, used in electrical radiation detectors, optical radiation measurement, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

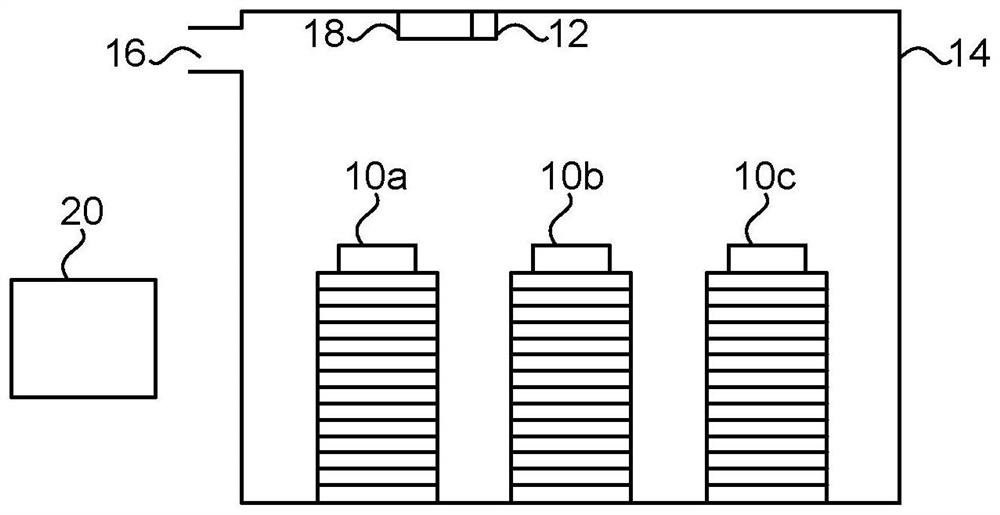

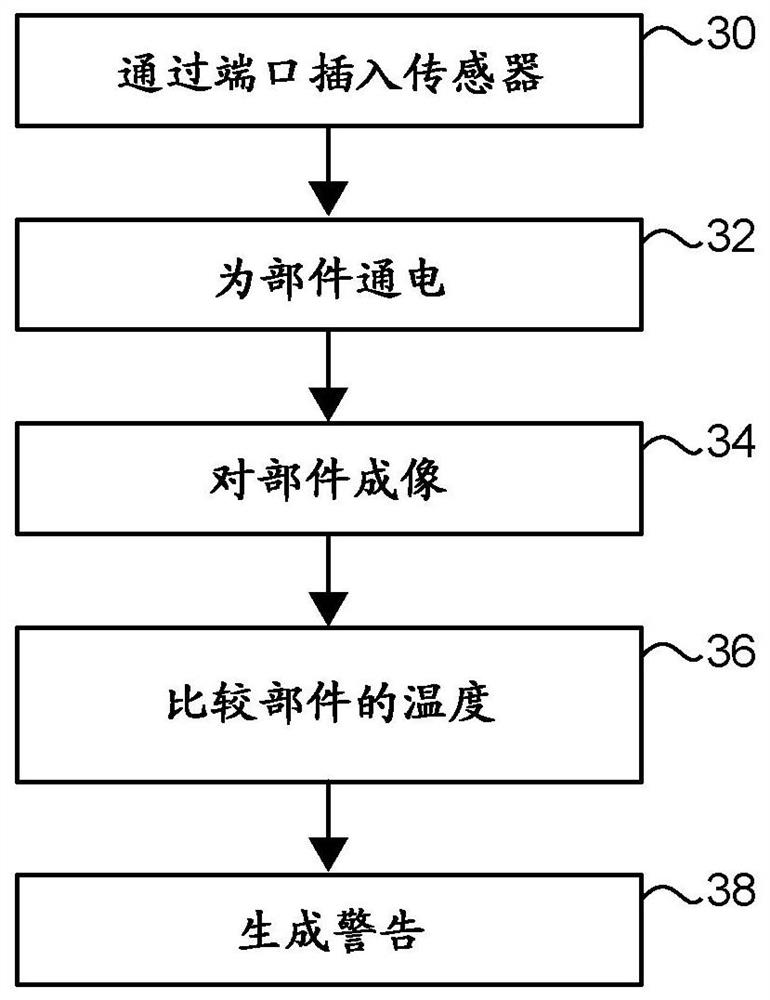

[0007]figure 1 A system for inspecting electrical equipment 10 is shown in andfigure 2A method of inspecting electrical equipment 10 is provided in. The system allows the electrical equipment 10 to be inspected when the equipment 10 is powered (32) to monitor the effective performance of the equipment 10. The system may use a thermal imaging sensor 12 (34) that images electrical components 10a, 10b, 10c in the device 10. The device 10 can be enclosed in an electrical cabinet 14, and the sensor 12 can be inserted into the cabinet 14 through a port 16. The image provides temperature data of the components 10a, 10b, and 10c in the image. The system compares the temperature data of the parts 10a, 10b, 10c in the image (36) and generates a warning (38) when the temperature change exceeds a threshold value.

[0008]Such asfigure 1 As shown, the electrical components 10a, 10b, 10c may be enclosed in an electrical cabinet 14. A port 16 may be provided for inserting the thermal imaging sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com