Multifunctional spraying equipment for forestry operation

A spraying equipment and multi-functional technology, which is applied in the field of multi-functional spraying equipment for forestry operations, can solve the problems of complex installation and operation of spraying equipment, increase maintenance cost, and affect spraying work, so as to achieve simple structure and reduce maintenance amount , The effect of prolonging the working life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

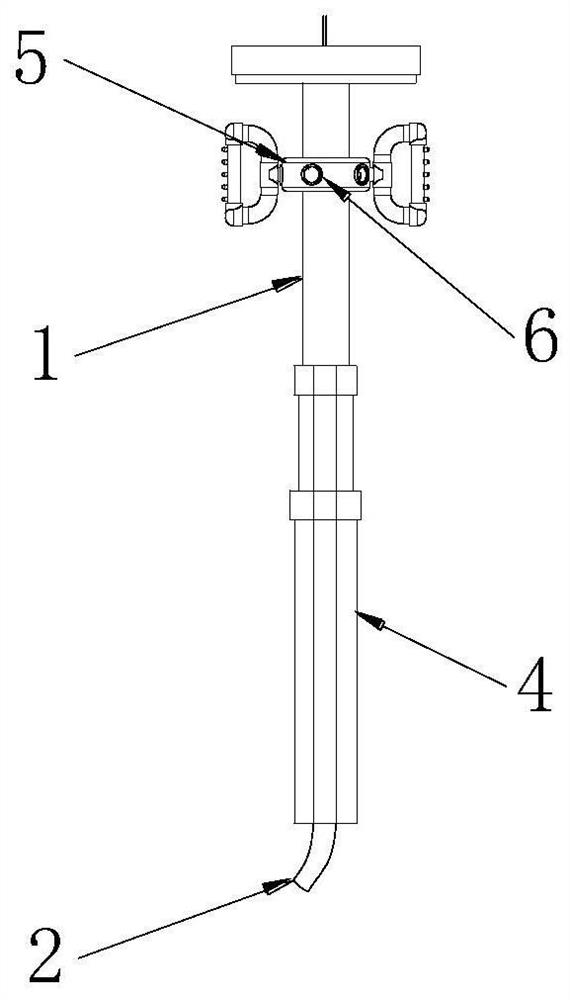

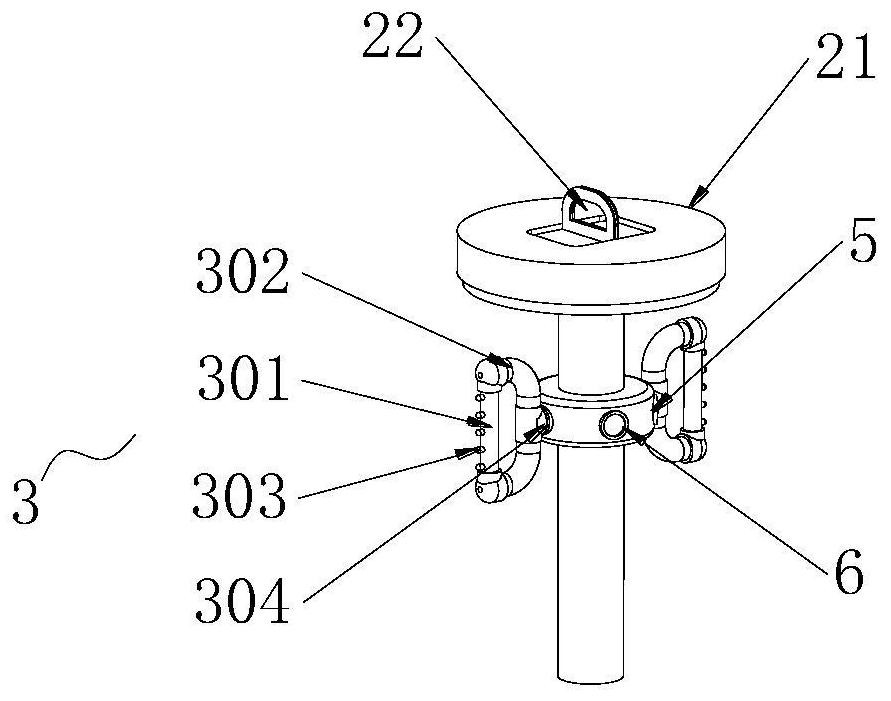

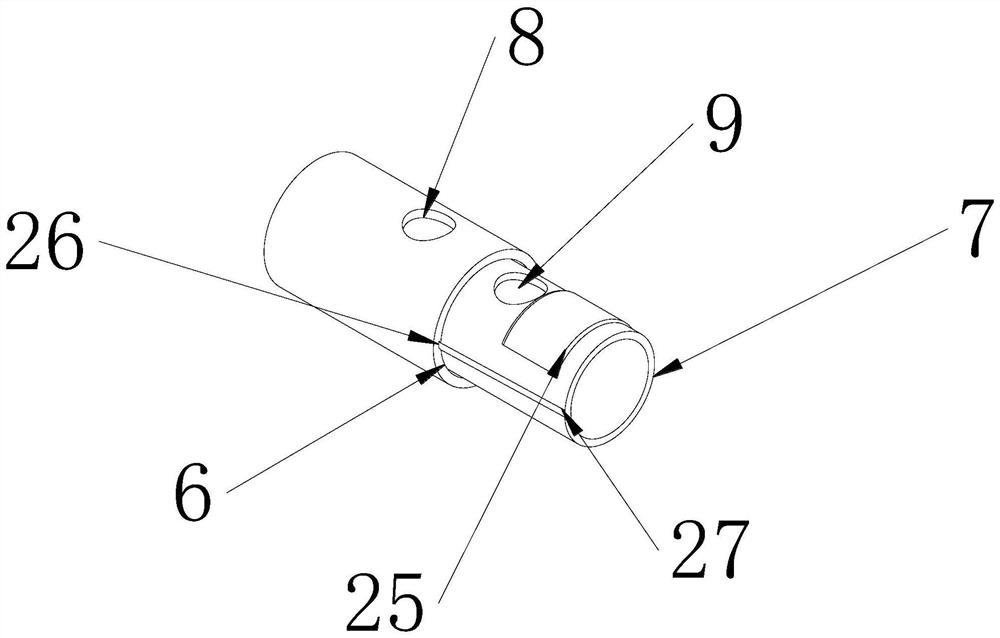

[0035] Example: such as figure 1As shown, a multi-functional spraying equipment for forestry operations includes a standpipe 1, a water delivery hose 2 and a sprinkler mechanism 3, a telescopic tube 4 is installed at one end of the standpipe 1, and one end of the water delivery hose 2 passes through the telescopic tube 4 It communicates with the standpipe 1, the other end of the standpipe 1 is provided with a rotating disk 5, the rotating disk 5 is free to rotate along the circumference of the standpipe 1 and the inner cavity of the rotating disk 5 communicates with the inside of the standpipe 1, and the side of the rotating disk 5 Several intubation tubes 6 are evenly opened, and a first connection hole 8 is provided on the inner wall of the intubation tube 6, and the intubation tube 6 communicates with the inner cavity of the rotating disk 5 through the first connection hole 8, and an inner tube is slidably installed in each intubation tube 6 7. There is a second connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com