Reinforcing structure for automobile b-pillar and installation method thereof

A technology for strengthening the structure and the B-pillar, applied in the superstructure, vehicle safety arrangement, superstructure sub-assembly and other directions, can solve the problems affecting the service life of the B-pillar, etc., to facilitate interior decoration, improve physical performance, and improve the speed of induction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

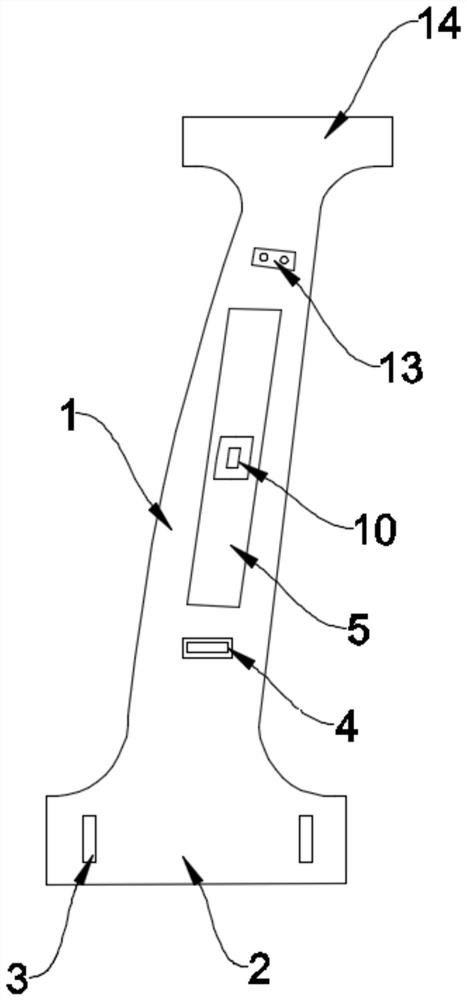

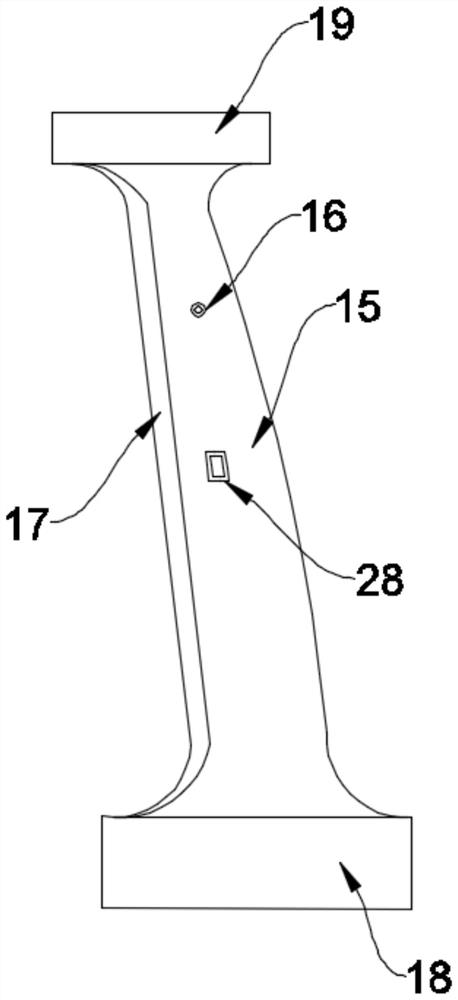

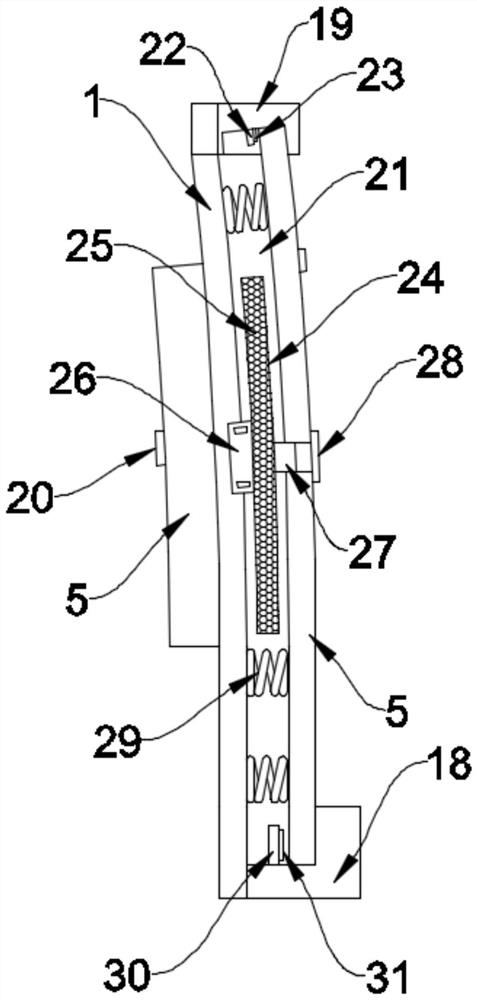

[0031] Such as Figure 1-5 As shown, a reinforced structure for a B-pillar of an automobile, comprising: a reinforced inner panel 1, a bottom beam 2 is provided at the lower end of the reinforced inner panel 1, and the bottom beam 2 is arranged in a rectangular beam shape, and the bottom beam 2 and The reinforced inner panel 1 is set in one body, the thickness of the bottom beam 2 is set to be consistent with that of the reinforced inner panel 1, and one side of the rear end of the bottom beam 2 is provided with an installation groove 3, and two installation grooves 3 are provided. The installation groove 3 is arranged in a rectangular groove shape, the depth of the installation groove 3 is set to be consistent with the thickness of the bottom beam 2, and the two instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com