Web combined type printing equipment and working method thereof

A printing equipment and combined technology, applied in the field of web combined printing equipment, can solve the problems of lack of winding mechanism and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

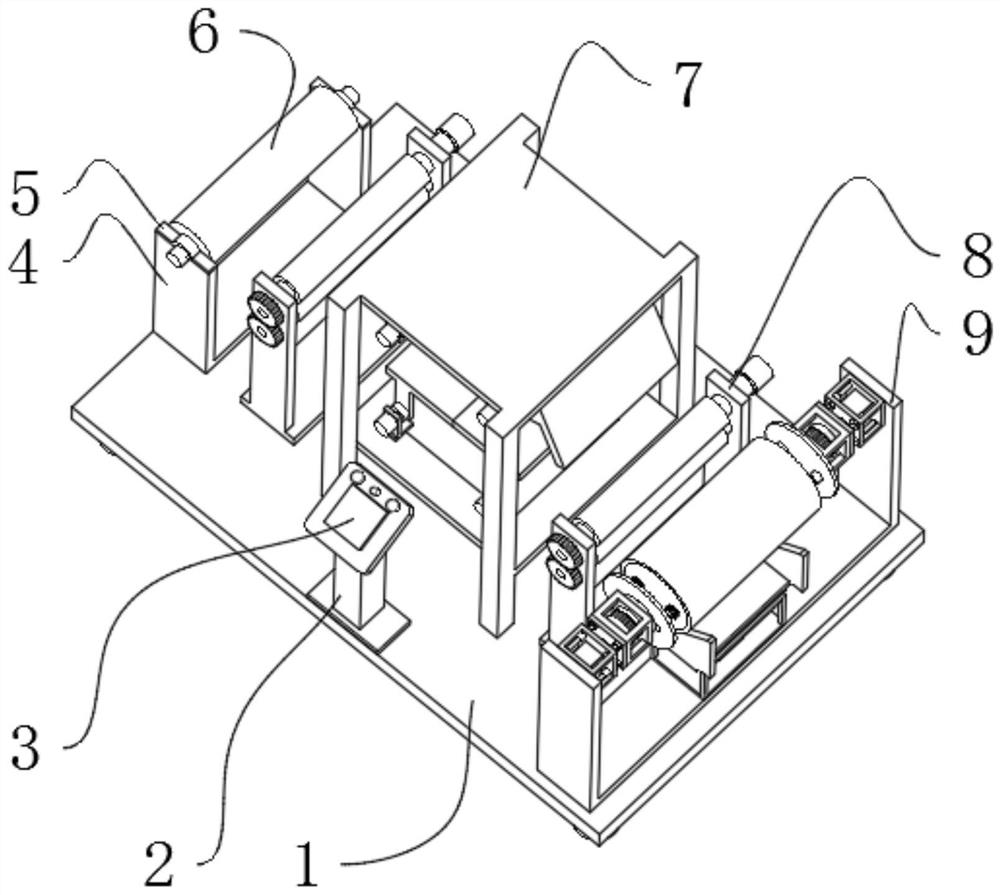

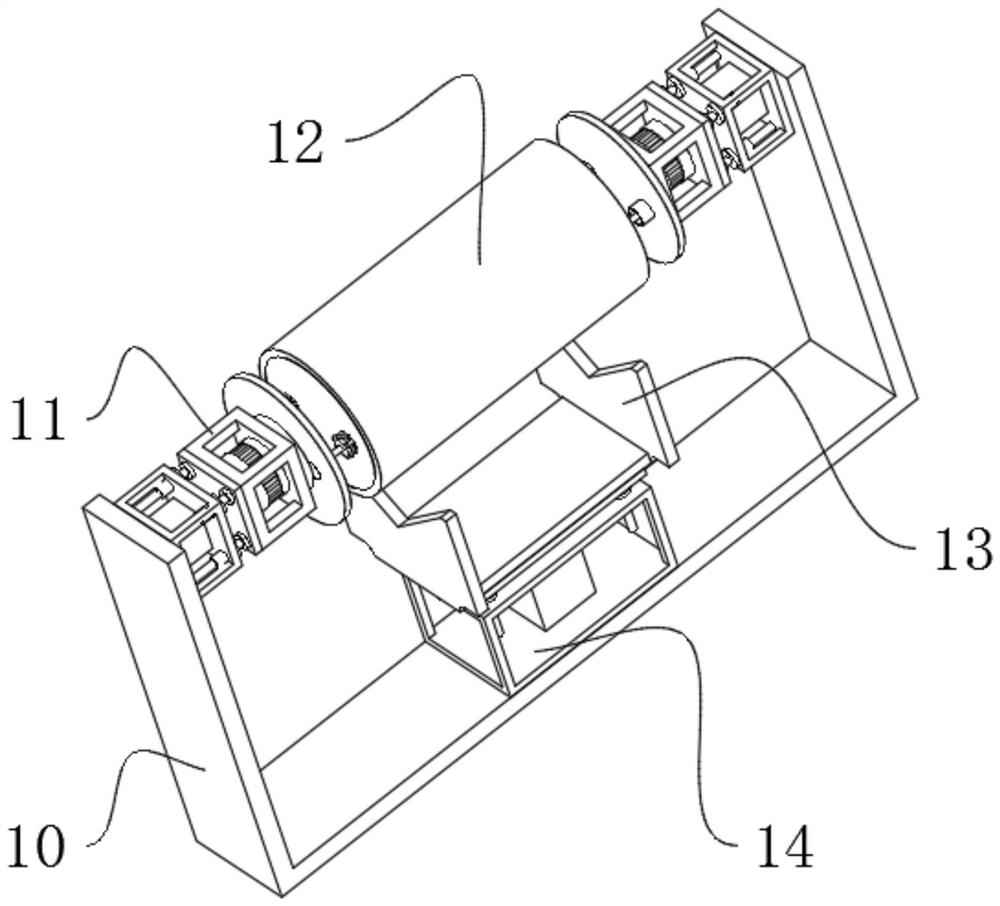

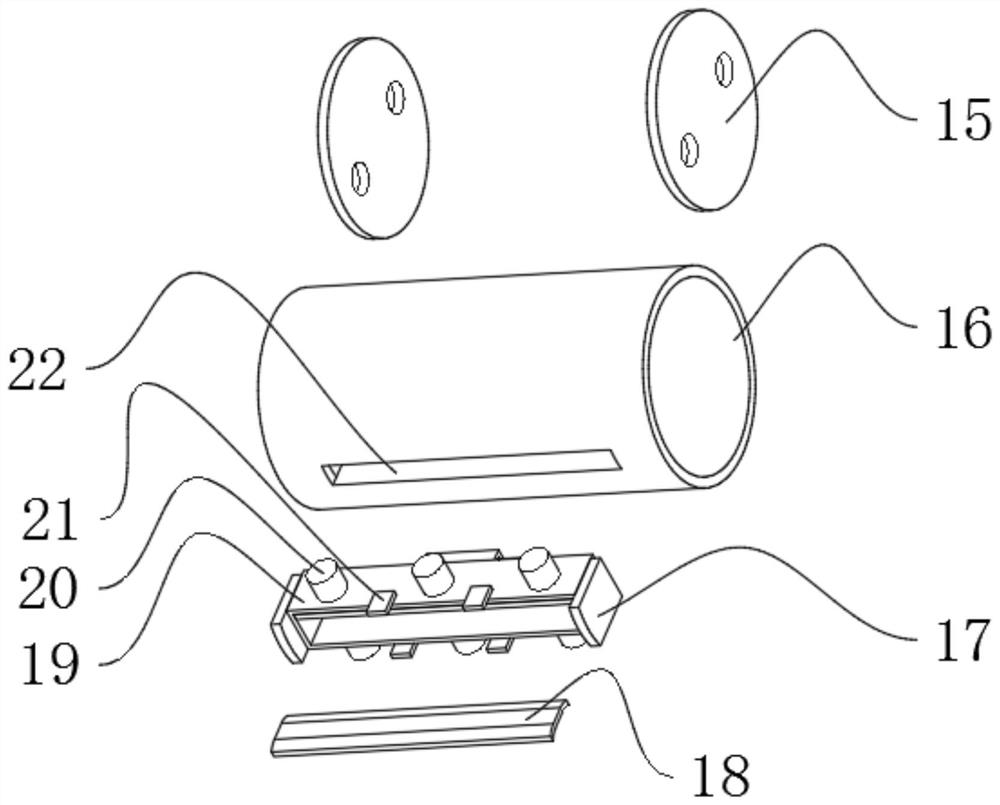

[0041] A web combined printing equipment, such as Figure 1-7 As shown, it includes the base plate 1, the top outer wall of the base plate 1 is fixedly connected with a printing support 7, and the printing support 7 is provided with printing components inside. The number of printing components is two groups, and they are installed in opposite directions. The drive assembly 8 and the winding mechanism 9, the winding mechanism 9 includes a winding support 10 and a reel assembly 12, the outer wall of the bottom of the rolling support 10 is fixedly connected to the outer wall of the top of the bottom plate 1, and the inner walls of both sides of the rolling support 10 are fixedly connected There is a rotary assembly 11, the outer wall of one side of the rotary assembly 11 is fixedly connected with a plunger assembly 27, the reel assembly 12 is fixedly connected to the outer wall of the plunger assembly 27, the reel assembly 12 includes a reel 16 and a cover plate 15, and the cover ...

Embodiment 2

[0046] A working method of web combined printing equipment, such as Figure 1-7 As shown, its method of use includes the following steps;

[0047] S1: place the raw material; place the raw material cylinder 6 wrapped with the raw material paper roll on the raw material support 4, and fasten the crimping plate 5;

[0048]S2: traction and fixation; the traction paper head passes through the first driving assembly 8, then passes through the printing support 7, then passes through the second driving assembly 8, and finally is fixed on the winding assembly 12;

[0049] S3: clamp the terminal; insert the end of the raw paper between the splints 18, and then start the clamping cylinder 20 to drive the splint 18 to clamp the paper;

[0050] S4: printing; when the paper needs to be printed on the front side, the closing plate 37 of one group of printing components is opened, the printing template 38 is pushed out, and the printing work is carried out, while the closing plate 37 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com