Reinforced sintering equipment, charge level cooling device and control method of charge level cooling device

The technology of a cooling device and a control method, which is applied in the field of sintering, can solve the problems of rising defective rate of sintered ore, inability to realize enhanced sintering, easy burnout of gas injection device pipe row facilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

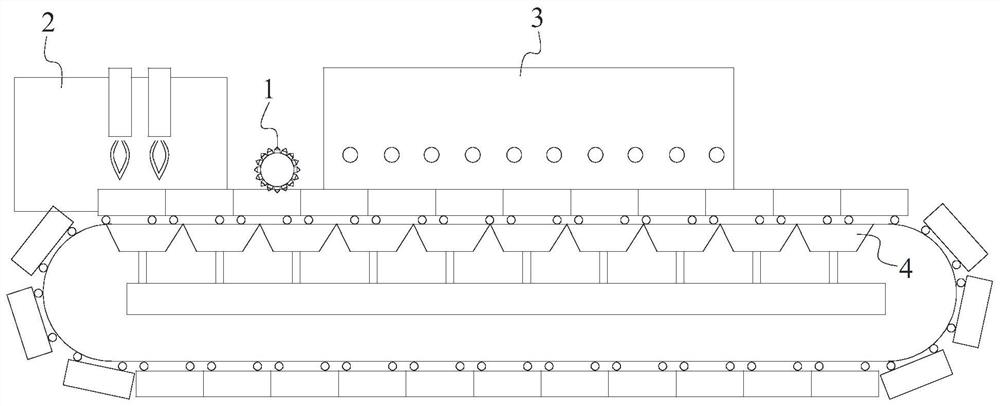

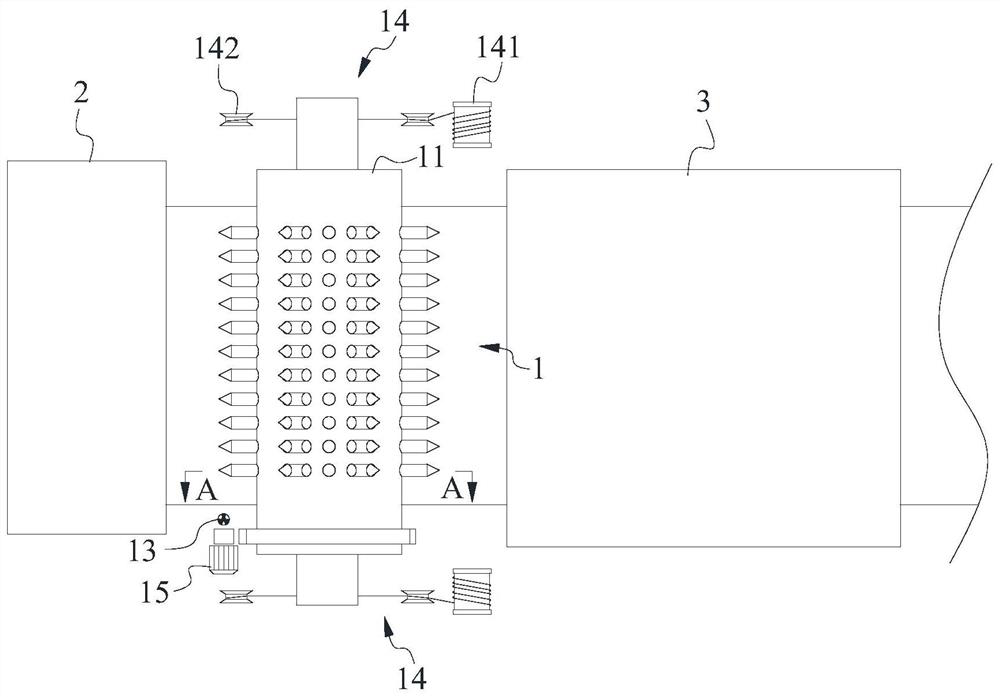

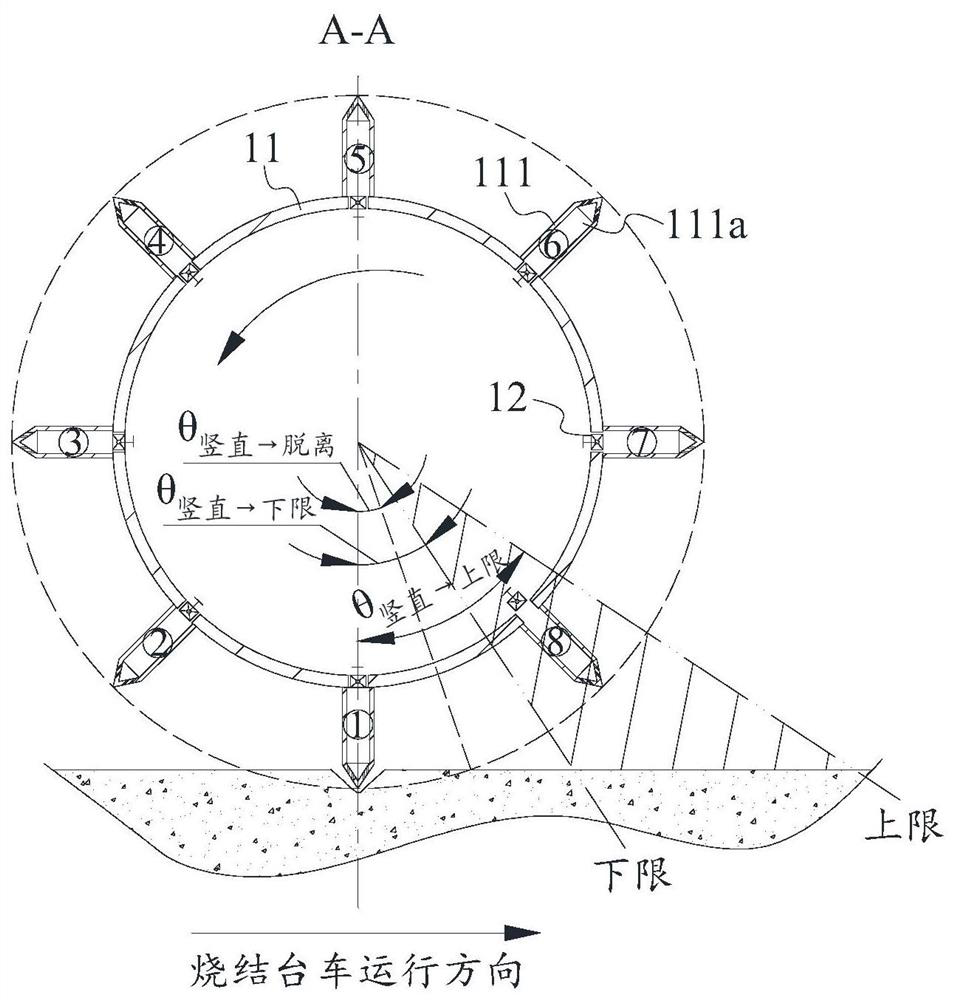

[0040] like Figure 1-4 As shown, the present invention provides a material surface cooling device. The material surface cooling device 1 is arranged next to the ignition device 2 in the sintering equipment, and is located downstream of the ignition device 2 and above the sintering material layer. In detail, the material surface cooling device 1 includes a rotating drum 11, which can be driven to rotate by a driving component. Specifically, the driving component can be a driving motor 15, which can be directly connected to the rotating drum 11, or can be provided with a variable speed. Mechanism; the cylinder wall of the drum 11 is provided with a number of rods 111. During the rotation of the drum 11, at least some of the rods 111 can be at least partially inserted into the sintered material layer, and the drum 11 is also filled with cooling fluid, and at least some of the rods The body 111 is hollow, so as to form an injection channel 111a inside; each hollow rod body 111 ca...

Embodiment 2

[0067] The present invention also provides an intensified sintering device, comprising a gas injection device 3 and a material surface cooling device 1, the gas injection device 3 is arranged next to the material surface cooling device 1, and is located downstream of the material surface cooling device 1, wherein the material The surface cooling device 1 is the material surface cooling device 1 involved in the first embodiment above.

[0068] Since the above-mentioned material level cooling device 1 already has the above technical effects, then the intensified sintering equipment having the material level cooling device 1 should also have similar technical effects.

Embodiment 3

[0070] like Figure 5 , Image 6 As shown, the present invention also provides a control method for a material surface cooling device, which is suitable for the material surface cooling device involved in Embodiment 1, including:

[0071] Step S1, obtaining the rotation angle α of the drum at different times;

[0072] Step S2, compare θ 竖直→下限 , θ 竖直→上限 , θ 竖直→i,0 、α t Whether it satisfies θ 竖直→下限 ≤((θ 竖直→i,0 +α t %2π)%2π)≤θ 竖直→上限 condition, if yes, perform the following step S3, if not, perform the following step S4;

[0073] Step S3, controlling the on-off valve of the hollow rod body numbered i to be in an open state;

[0074] Step S4, controlling the on-off valve of the hollow rod body numbered i to be in a closed state;

[0075] Among them, α t is the rotation angle of the drum at time t, θ 竖直→下限 , θ 竖直→上限 are the angles between the vertical position and the lower limit and upper limit of the injection station in the direction of rotation, θ 竖直→i,0 is the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com