Cultivation method capable of synchronously loosening soil, ditching, sowing and mulching film

A technology of mulching and seeding machine, which is applied in the fields of simultaneous loosening, sowing, mulching, and ditching, can solve the problems of troublesome ditching and sowing, laborious ditching, affecting the effect of sowing, etc., so as to achieve uniform sowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

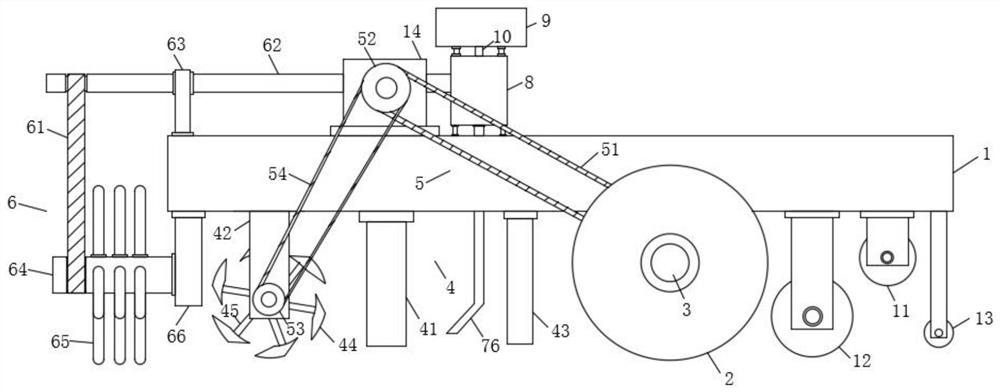

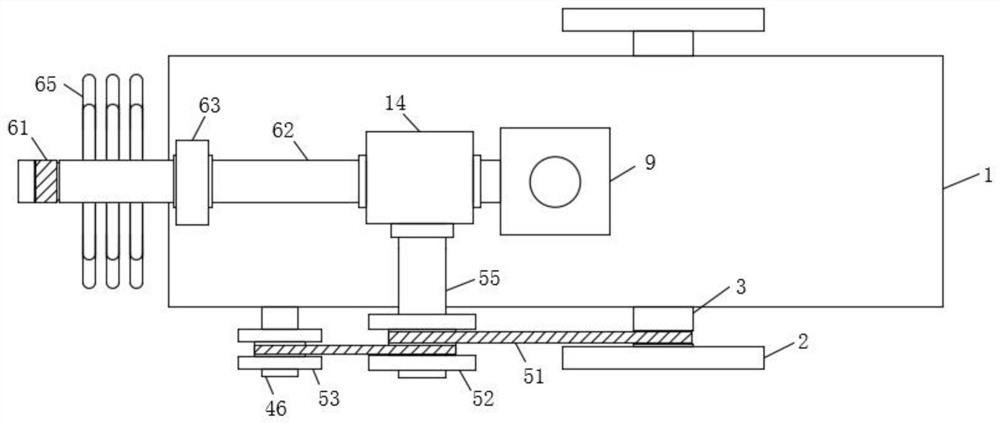

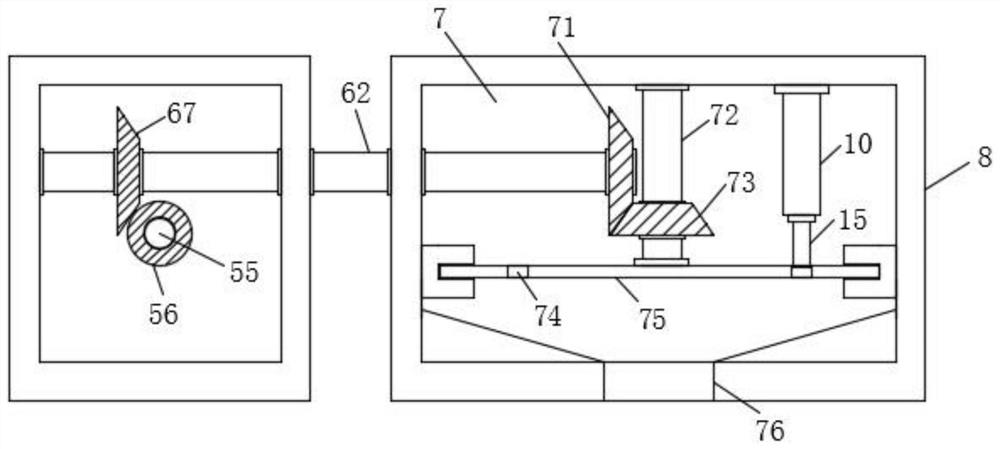

[0031]Such asFigure 1-Figure 7As shown, the cultivation method of the present invention for simultaneous soil loosening, ditching, seeding, and film mulching includes the following steps:

[0032]S1: Drive the entire film planter to move through external power equipment;

[0033]S2: During the movement of the film-covered planter in S1, use the cleaning rod rotating on the film-covered planter to clean up the straw on the ground;

[0034]S3: While cleaning the straw in S2, use a number of rotating loose soil blocks on the film-covered planter to loosen the ground, and the loosened soil is then ditched through the ditch board;

[0035]S4: After the trench is opened in S3, after seeding is carried out through the seed box on the film-covered planter, the two soil cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com