Special hill-seeding mechanism for hill planter and non-displacement precise hill planter

A hole-seeding machine with precise technology, applied in the direction of interval-type quantitative seeding machinery and other directions, can solve problems such as seed displacement, and achieve the effect of convenient adjustment of hole distance and good consistency of seeding depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

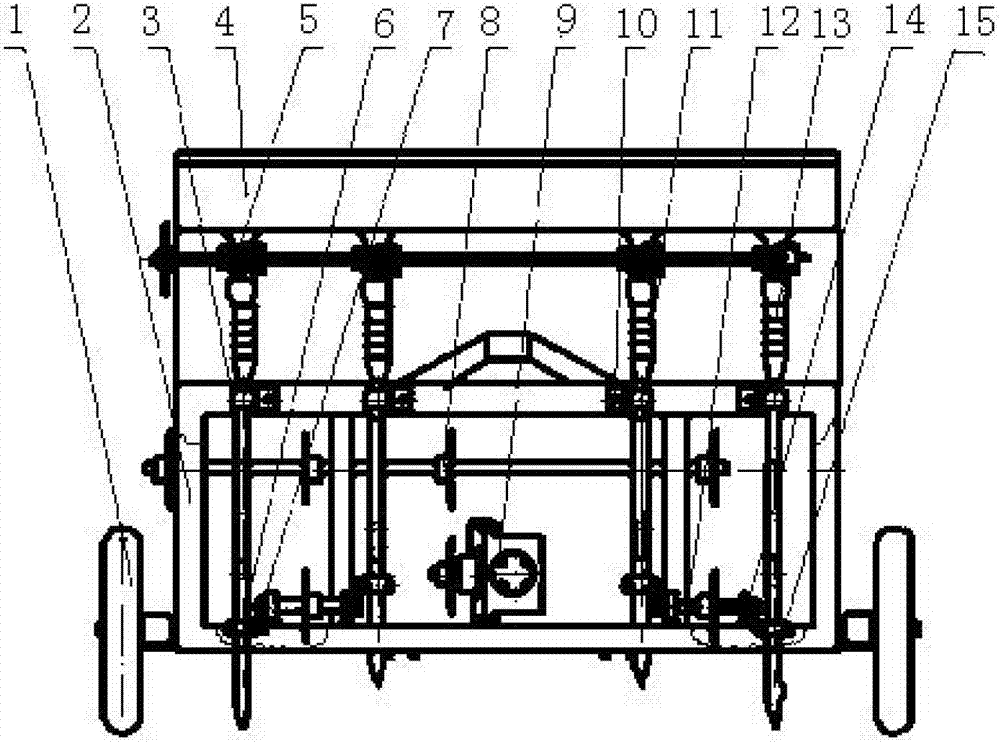

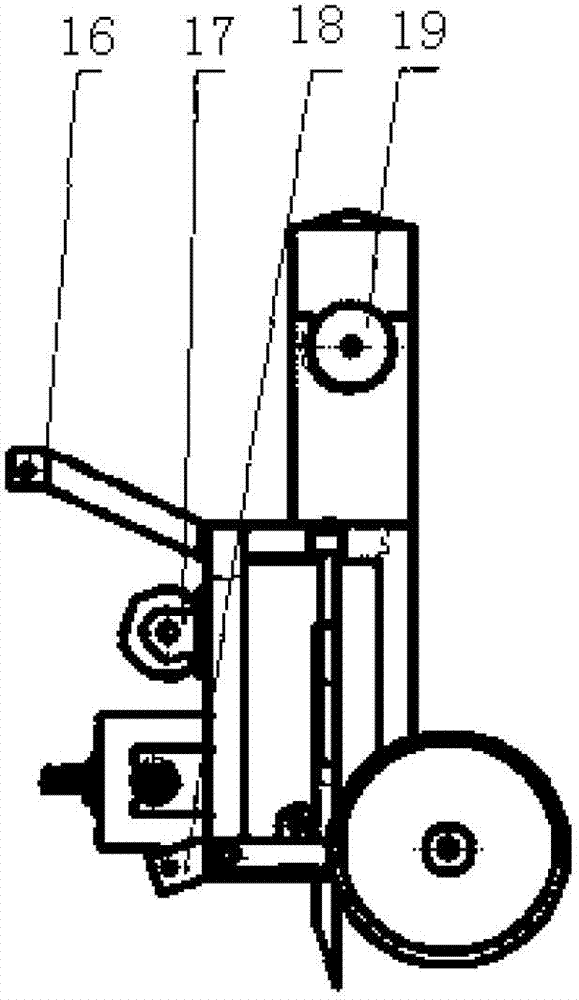

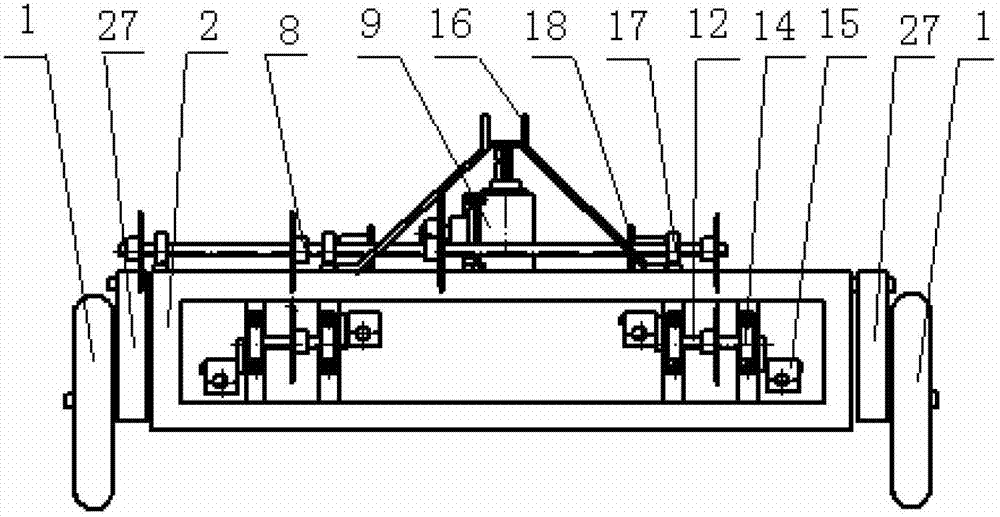

[0012] According to attached Figure 1-5 Specific embodiments of the invention are given.

[0013] Specifically, the design of the non-displacement precision hole seeder is: there are ground wheels 1 on both sides of the frame 2 to support most of the weight of the hole seeder, the top of the frame 2 is equipped with a seed box 4, and the bottom of the seed box 4 is equipped with a precision seeding machine. Device 5, the lower part of the precision seed metering device is connected with a funnel and a seed delivery pipe 13, the lower end of the seed delivery pipe 13 is inserted into the upper pipe hole of the upper point seeding pipe 3, and the upper end of the upper point seeding pipe 3 is inserted into the pipe ring 11, fixed with screws, and the pipe ring The platform column body on the 11 is in the hole of the pipe ring assembly bending plate 10, and the clearance fit is used for locking with double nuts. Rocks back and forth, but doesn't move up and down.

[0014] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com