Fabric structure for improving fluff surface stability of warm-keeping product and application of fabric structure

A fluffy surface and stability technology, applied in the field of thermal insulation fabrics, can solve the problems of maintaining a fluffy state, the fluff of the fabric is easy to be flattened, and the fluff is easy to be flattened again, so as to achieve the effect of improving the thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

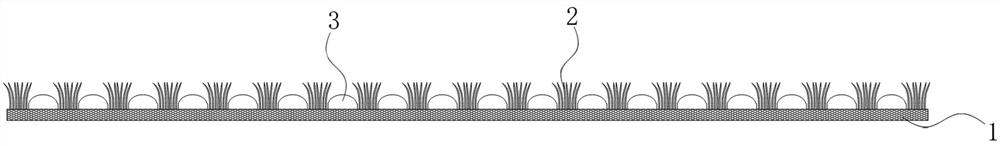

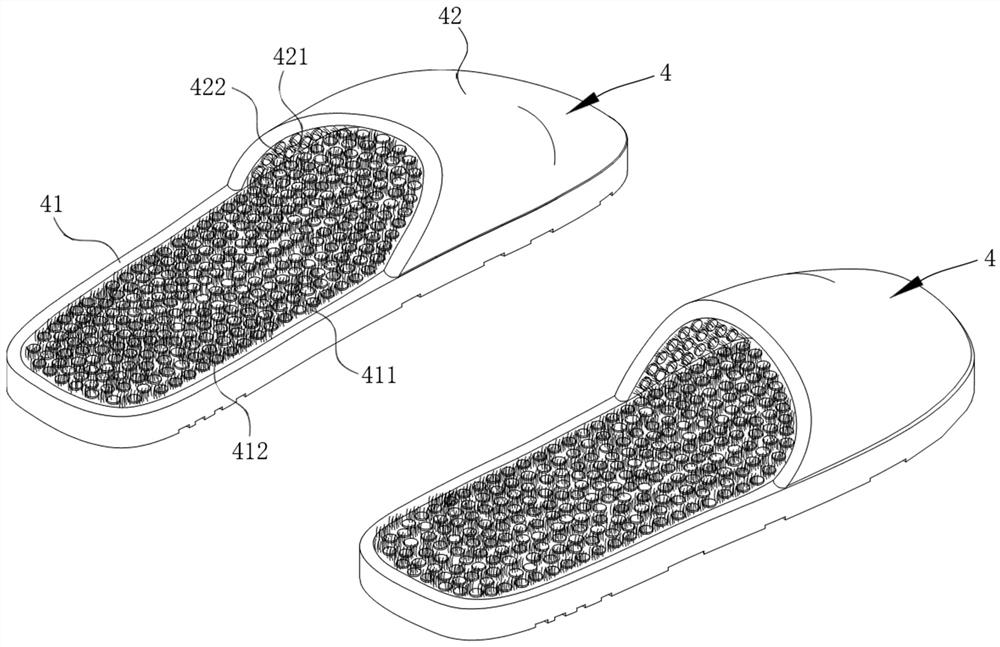

[0048] Embodiments of the present invention provide a figure 1 The fabric structure shown based on improving the stability of the fluff surface of thermal products includes a fluff fixing surface 1, warm fluff 2 and limiting bumps 3; it is used to replace the fluff fixing surface 1 through the limiting bumps 3 as a human body contacting the fabric. The support surface during the structure avoids direct contact with the root of the heat-preserving fluff 2, so as to effectively prevent the heat-preserving fluff 2 from being crushed during use, realize the ability to maintain a fluffy state for a long time, and improve the functional practicability of the structure. The specific settings are as follows:

[0049] The fluff fixing surface 1 is fixedly provided with several groups of warm fluffs 2 arranged at intervals, and a limiting protrusion 3 is arranged between any two groups of the warm fluffs 2, and the adjacent warm fluffs 2 and the The space-limiting protrusions 3 are arr...

Embodiment 2

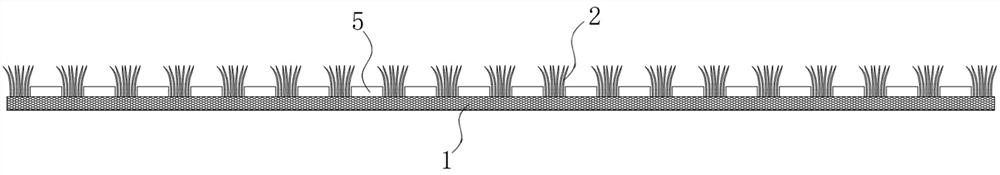

[0061] In embodiment 2, for the same structure as in embodiment 1, give the same symbol, omit the same description, embodiment 2 has made improvement on the basis of embodiment 1, as Figure 3-4 As shown, the position-limiting bump 3 adopts the position-limiting block 5, which is equivalent to connecting several of the position-limiting protrusions 3 uniformly to ensure that there is no gap between any two of the position-limiting protrusions 3. There is a gap, thereby further ensuring that the warm-keeping fluff 2 will not be folded between two adjacent limiting protrusions 3, and the structural stability of the warm-keeping fluff 2 is better.

[0062] Specifically, please continue to refer to Figure 4 , the position-limiting block 5 is in the shape of a flat plate evenly provided with several notches, and several groups of the warm-keeping fluffs 2 are fixed on the fluff fixing surface 1 and accommodated in several notches correspondingly one by one. The length of the part...

Embodiment 3

[0064] In embodiment 3, for the same structure as in embodiment 1 and 2, give the same symbol, omit the same description, embodiment 3 has made improvement on the basis of embodiment 1, as Figure 5 As shown, the warm fluff 2 includes a bump outer fluff 21 and a bump inner fluff 22; wherein, the bump outer fluff 21 is fixedly connected to the fluff fixed between several limit bumps 3 surface 1; the fluff 22 inside the bump is fixedly arranged on the fluff fixing surface 1 corresponding to the plurality of limit bumps 3 .

[0065] The distance between any two adjacent limiting protrusions 3 is less than 1 / 2 of the overall extension length of the outer fluff 21 of the protrusion; The extension height is greater than the vertical height of the limit bump 3 relative to the fluff fixing surface 1; They are all equal, and the inner fluff 22 of the adjacent bump and the outer fluff 21 of the bump are closely interlaced.

[0066] The advantage of this embodiment is that it can furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com