Smart factory fire-fighting inspection system

An inspection system and factory technology, applied in the direction of fire alarms and fire rescues that rely on the effect of smoke/gas, can solve problems such as unsuitable manual inspections, unsuitable use of sprinkler fire protection systems, etc., to reduce the impact, Ensuring continuous and reliable operation and the effect of precisely pinpointing firefighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

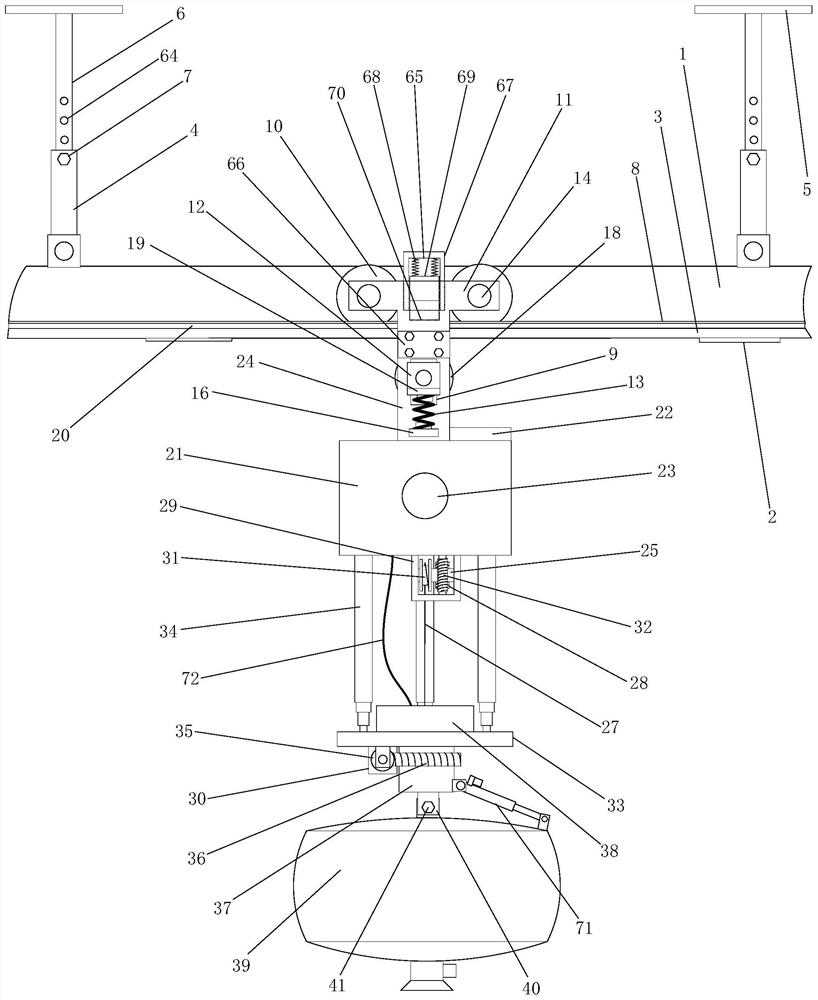

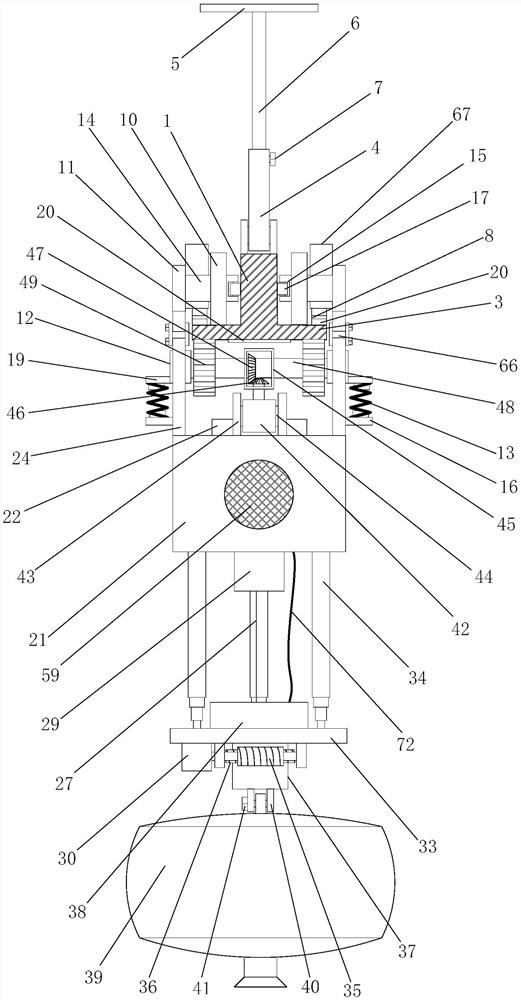

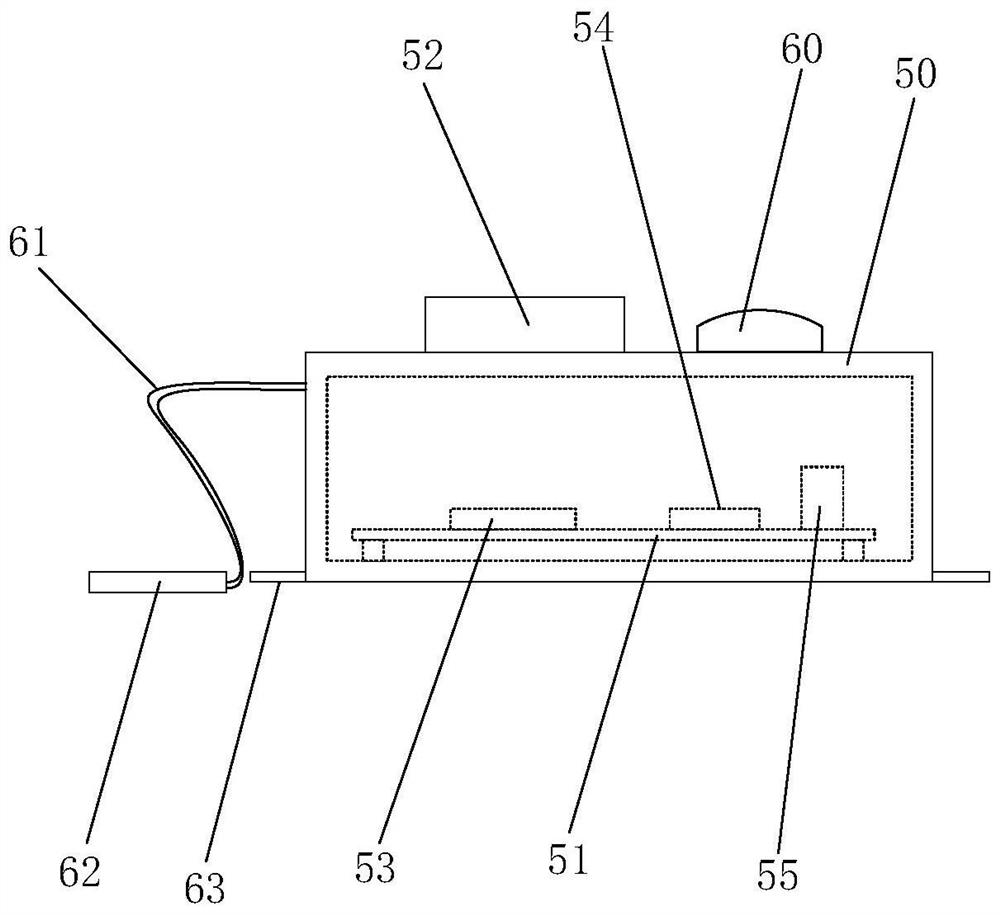

[0025] Such as Figure 1-4 As shown, the intelligent factory fire inspection system disclosed in the present invention includes: a walking track 1, a mobile fire extinguisher and alarm sensor nodes for installation at each detection point; the mobile fire extinguisher is controlled by a mobile mounting mechanism, Box 21, steel rope lifting mechanism, angle adjustment mechanism and electric control dry powder fire extinguisher 39 constitute;

[0026] On the upper side of the walking track 1, each suspension installation mechanism is arranged at intervals; the suspension installation mechanism includes a height adjustment sleeve 4, a height adjustment rod 6 and a top mounting plate 5; the lower end of the height adjustment sleeve 4 is hingedly installed on On the upper side of the walking track 1; the upper end of the height adjustment rod 6 is fixedly installed on the top mounting plate 5; the lower end of the height adjustment rod 6 is inserted in the height adjustment sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com