Welding machine

A welding machine and welding mechanism technology are applied to the welding machine. It can solve the problems that affect the price and quality, and the movement is prone to errors, so as to avoid multiple positioning and ensure the price and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

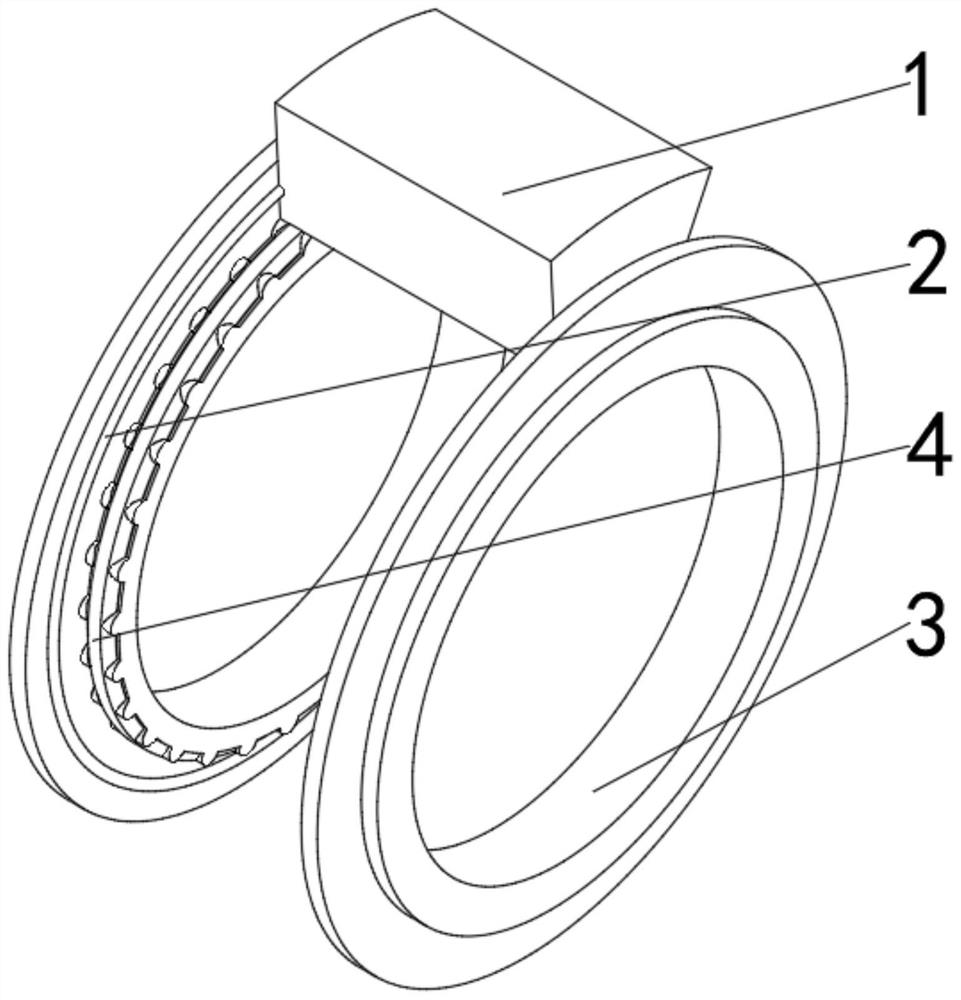

[0041] see Figure 1-7 , the present invention provides a technical solution: a welding machine, including a welding mechanism 1, an external power supply mechanism 2 is movably connected to the middle and lower positions of the outer walls on both sides of the welding mechanism 1, and the side of the external power supply mechanism 2 away from the welding mechanism 1 is fixedly connected to a Limiting the driving mechanism 3, the outer surface of the limiting driving mechanism 3 close to the external power supply mechanism 2 is movably connected with a trigger mechanism 4;

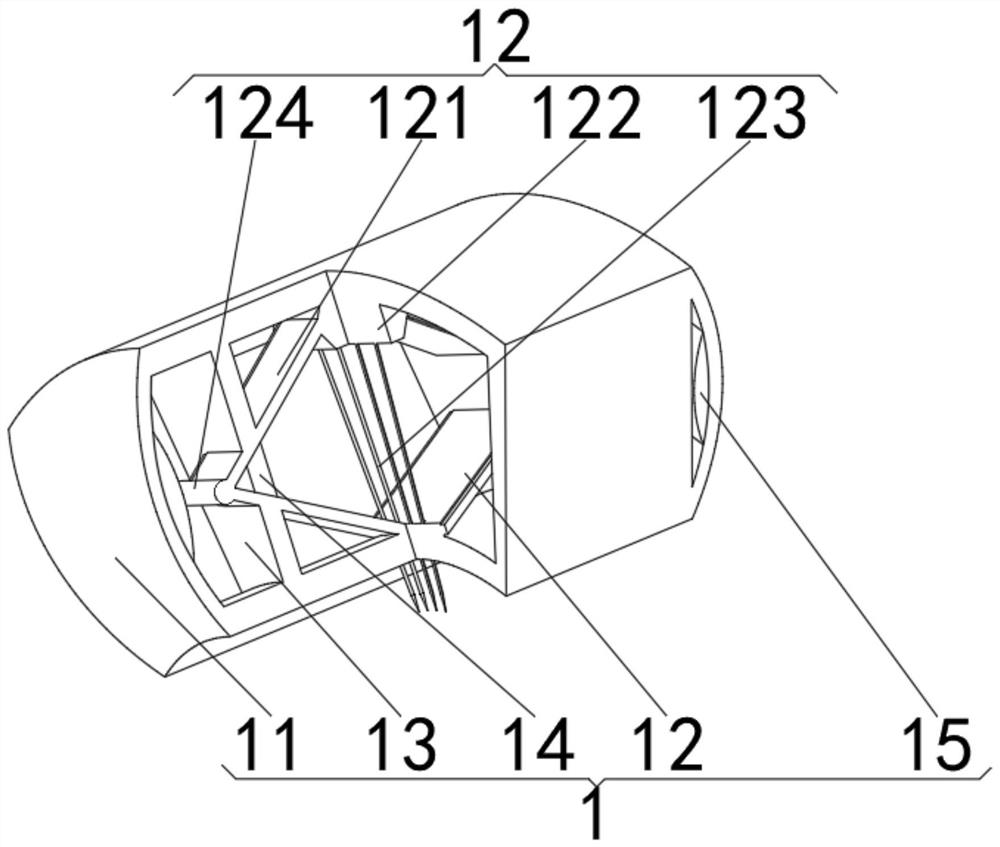

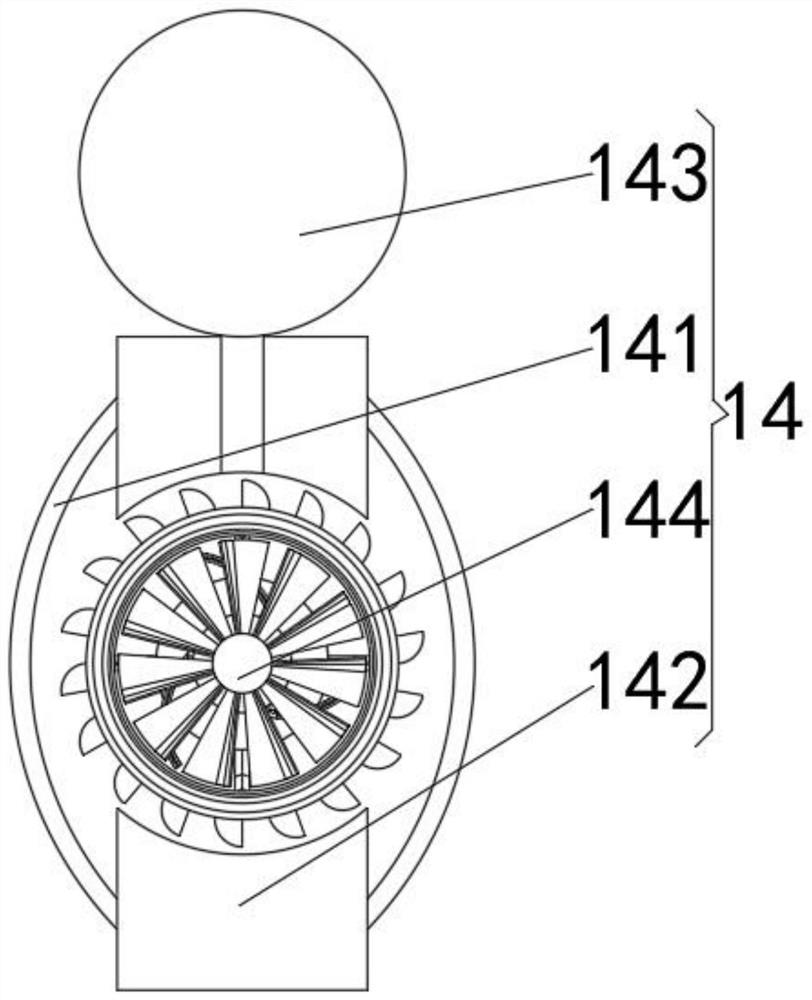

[0042] The welding mechanism 1 includes a welding box 11. A rhombus welding mechanism 12 is arranged in the middle of the inner cavity of the welding box 11. The inner cavity of the welding box 11 is located on both sides of the rhombus welding mechanism 12 and is fixedly connected with a partition plate 13. The two sides of the inner cavity of the rhombus welding mechanism 12 A temperature control mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com