A method of manufacturing a windshield wiper gearbox housing

A manufacturing method and a technology for a reduction gearbox, which are applied in the field of the production of the wiper gearbox housing, can solve the problems of inability to guarantee the processing accuracy of the product, affect the performance of the wiper, increase the input cost, etc., so as to save the clamping time, shorten the processing time, improve the The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

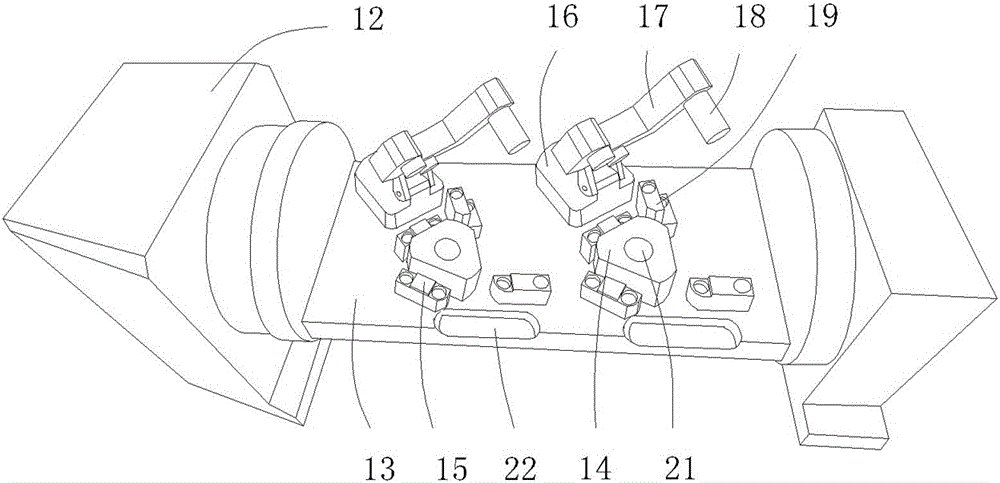

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

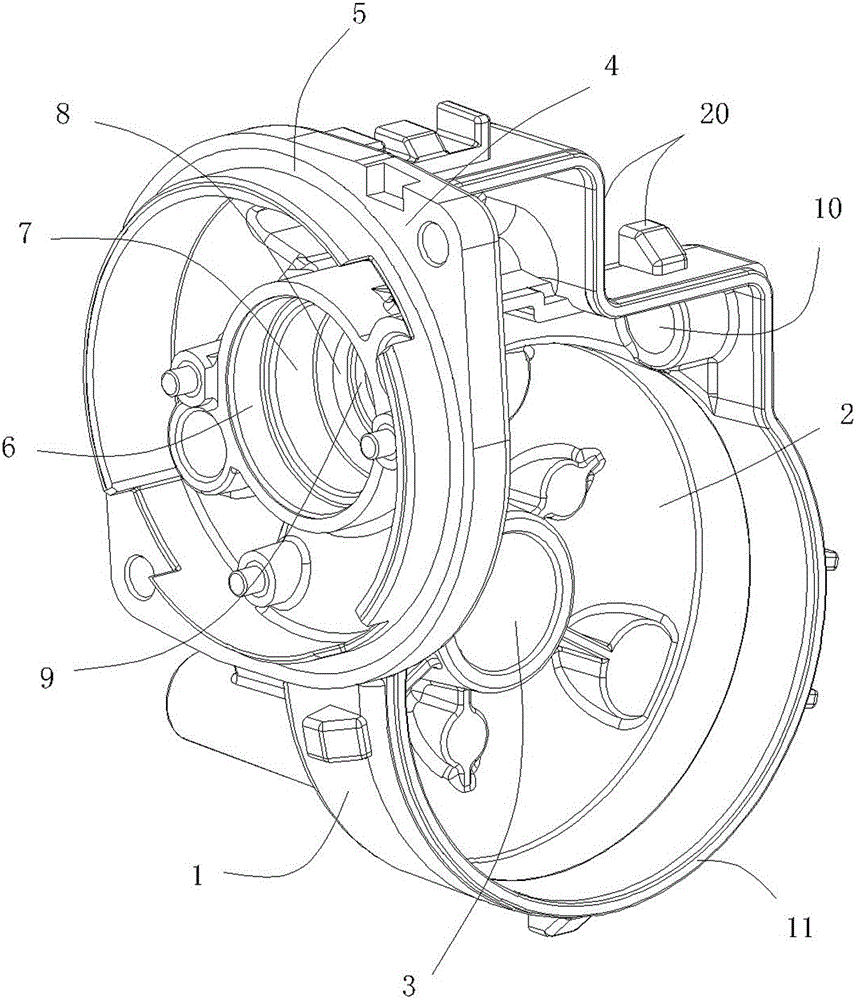

[0026] refer to figure 1 The housing 1 of the wiper gear reducer is provided with an accommodating cavity 2 with an opening on one side, and an output shaft hole 3 with a diameter of φ16.006mm runs through the inner wall of the accommodating cavity. The motor installation end face 4 with the opening end face perpendicular to it. The inner diameter of the motor installation end face is φ56.2mm, and there is a groove 5 with an inner diameter of φ56.2mm and a radian of R1 on it. A stepped hole for the motor shaft runs through the motor installation end face. The stepped hole is composed of the first hole 6, the second hole 7, the third hole 8 and the fourth hole 9 arranged sequentially from outside to inside. The diameter of the first hole 6 is φ25.05mm and the depth is 5.2mm. Hole 7 has a diameter of φ22.003mm and a depth of 6.6mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com