Double gantry single beam mobile combined processing machine tool

A combined processing, single beam technology, applied in metal processing equipment, grinding machine parts, grinding machines, etc., can solve the problems of affecting processing accuracy, workpiece damage, positioning errors, etc., to avoid multiple positioning and reduce processing errors. Introduction, the effect of simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

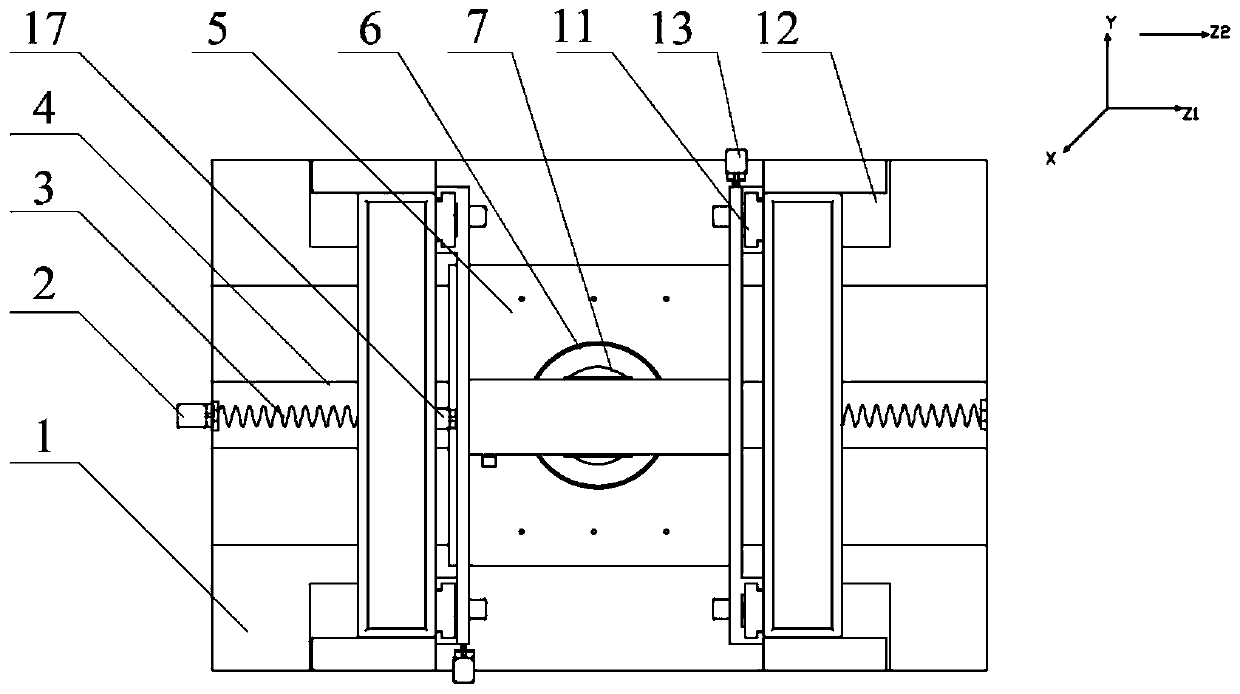

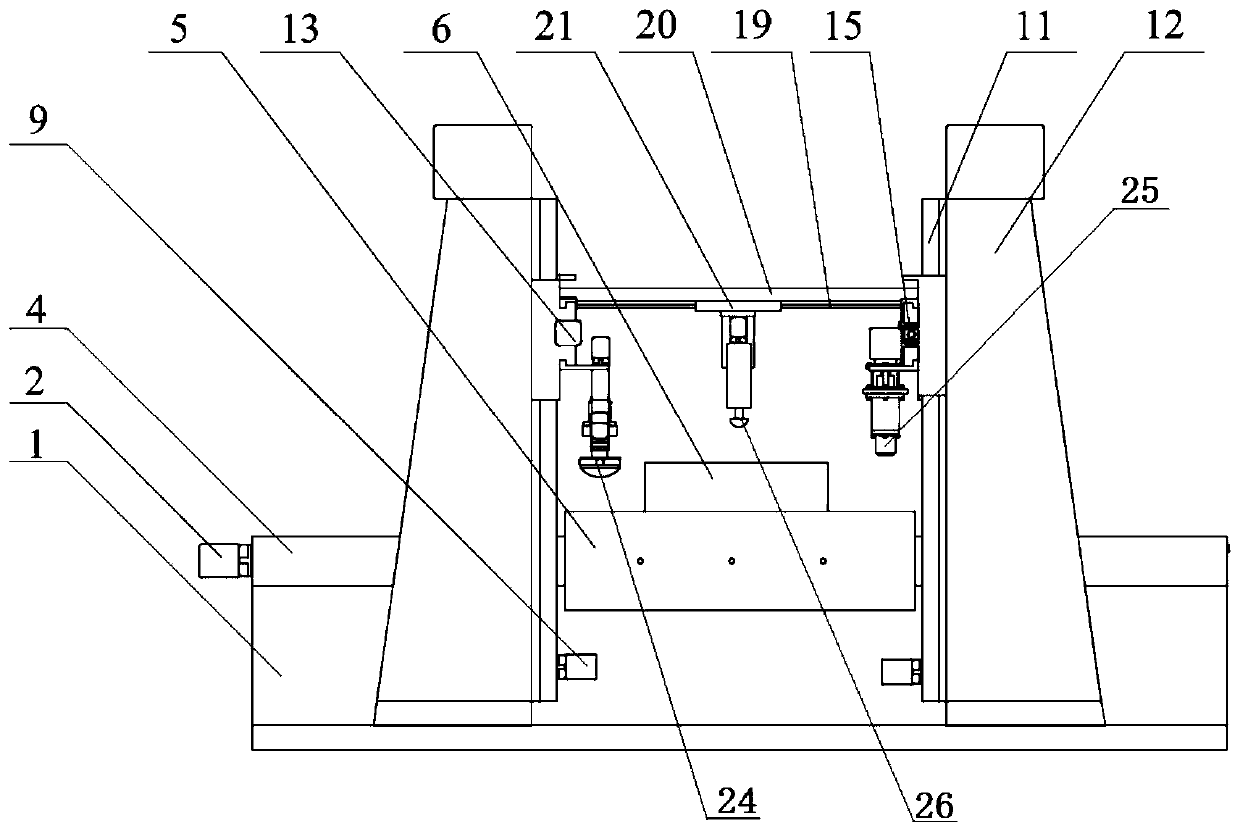

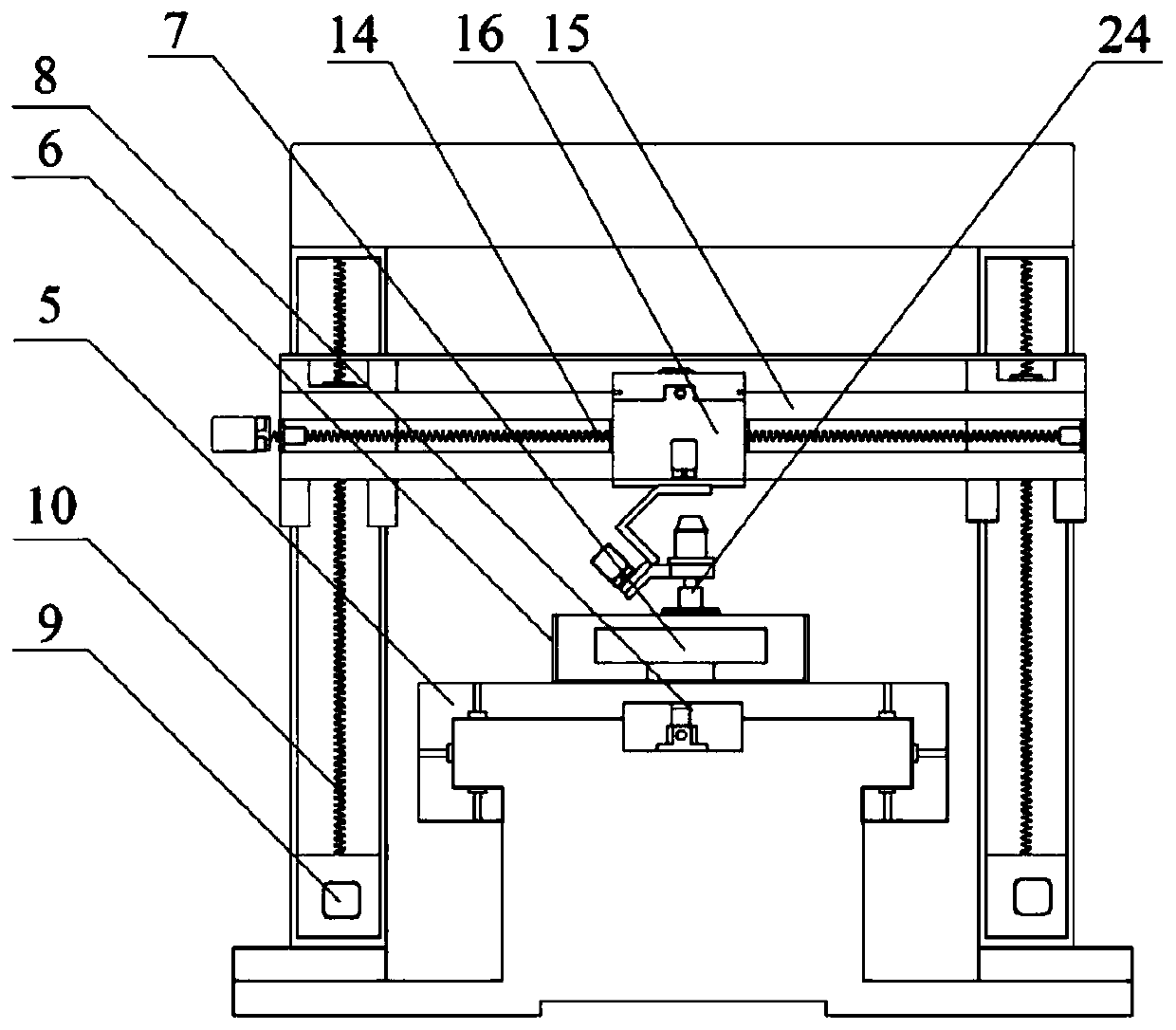

[0016] see Figure 1~4 , the embodiment of the present invention is provided with an airbag polishing process system, a small grinding head smoothing process system, and a jet polishing process system; the aforementioned three systems are always on the same straight line.

[0017] The present invention is provided with bed base 1, Z 1 Axis servo motor 2, Z 1 Shaft ball screw pair 3, Z 1 Axial static pressure guide rail 4, main table 5, collecting funnel 6, rotary table 7, main table connector 8, four Y-axis servo motors 9 (installed in pairs and arranged symmetrically), four Y-axis ball screws Vice 10 (installed in pairs and arranged symmetrically), Y-axis guide rails 11, four Y-axis guide rails 11 (installed in pairs and arranged symmetrically), two gantry columns 12, two X-axis servo motors 13, two X-axis balls Lead scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com