Polishing device for bamboo stick production and processing

A polishing device and bamboo stick technology, which is applied in the direction of grinding drive device, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low polishing efficiency, bamboo stick bump damage, poor polishing effect, etc., and improve polishing efficiency , Avoid bump damage, good polishing removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

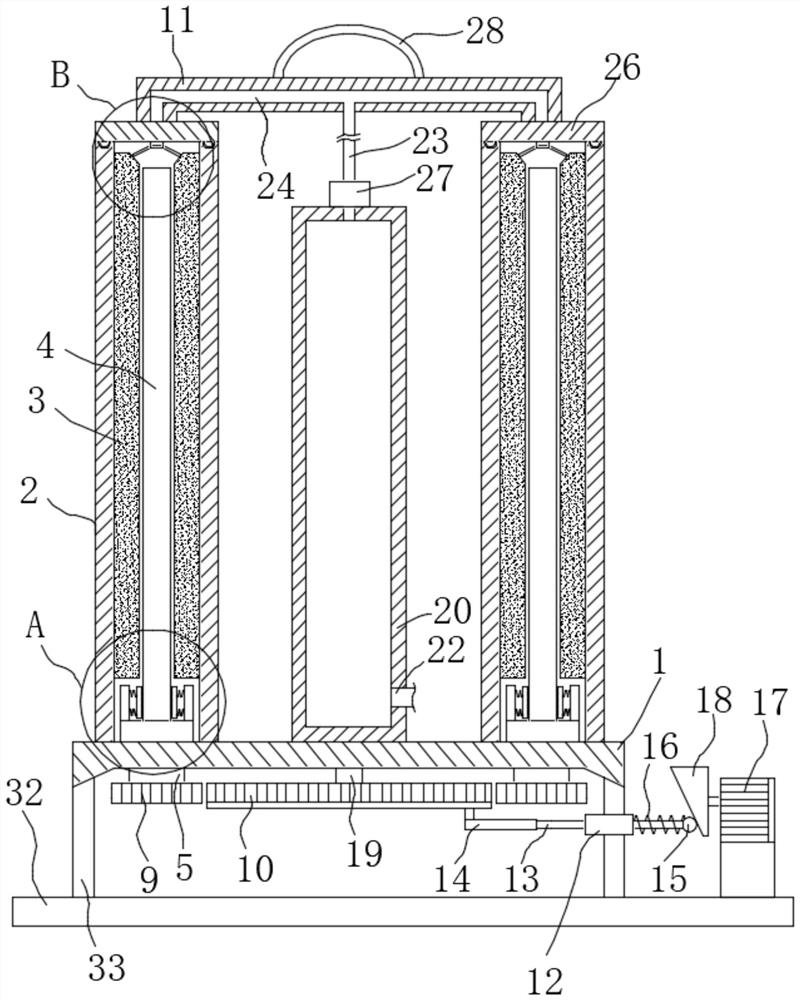

[0031] Please combine Figure 1 to Figure 5 The polishing device for bamboo stick production and processing includes a substrate 1 and a polishing device arranged on the substrate 1, the polishing device includes a plurality of polishing mechanisms surrounding the top of the substrate 1 in a circumferential direction and a driving mechanism for driving each polishing mechanism to rotate together . By driving multiple polishing mechanisms to rotate together, rapid polishing of multiple bamboo sticks 4 can be realized at the same time, and the polishing efficiency can be improved.

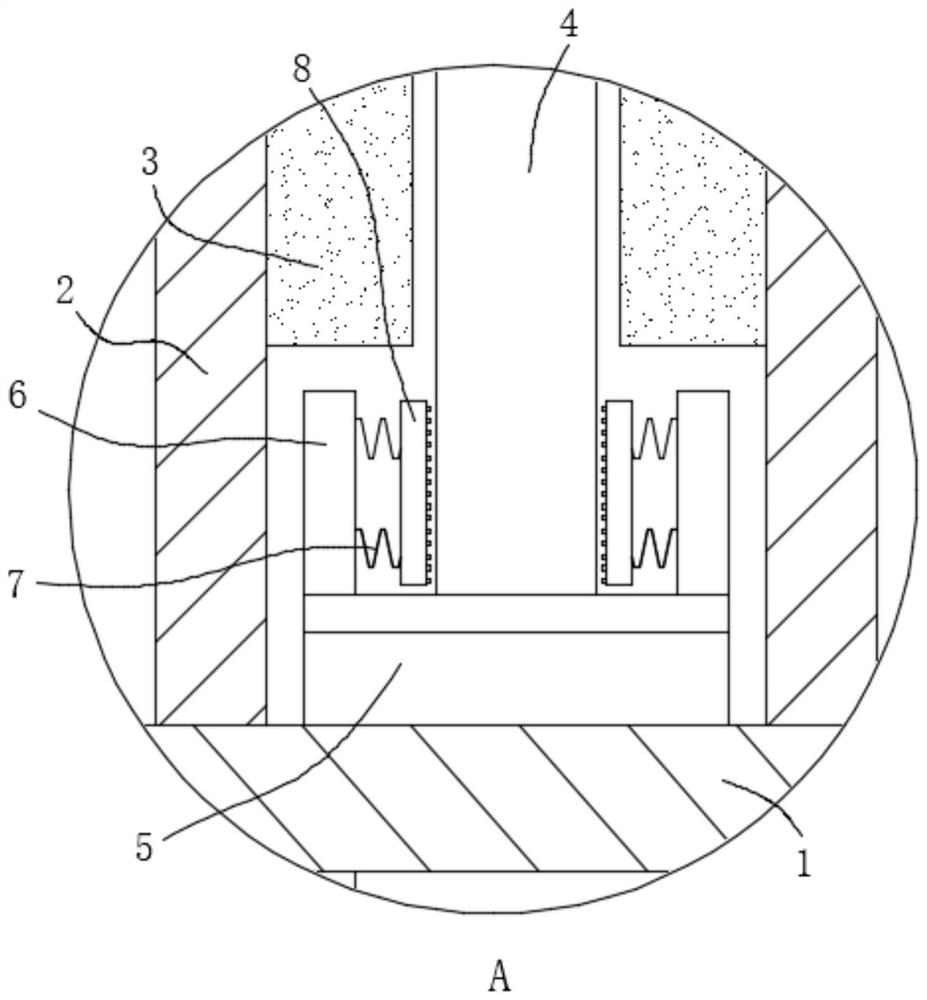

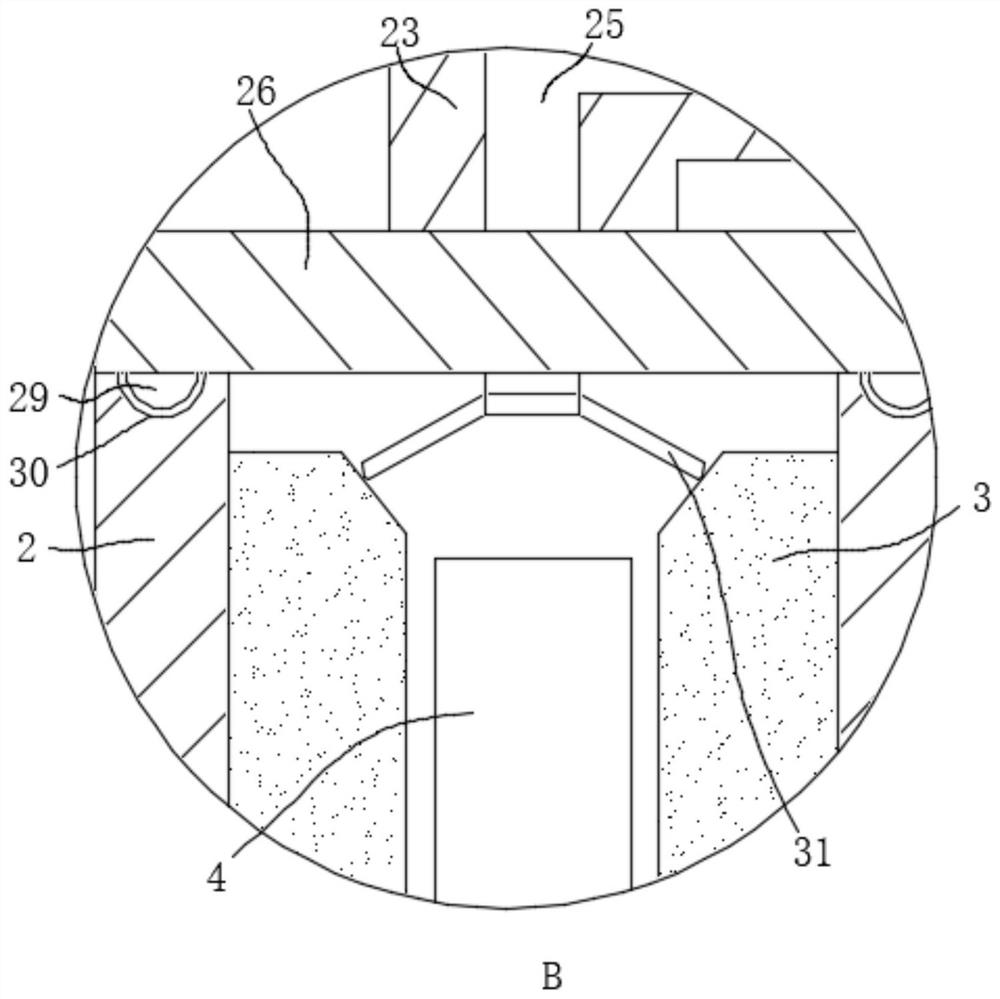

[0032] Each polishing mechanism includes an outer cylinder 2 and an inner cylinder 3 inserted in the outer cylinder 2 , the inner sidewall of the inner cylinder 3 has a frosted layer (not shown) for polishing the bamboo stick 4 . In this embodiment, both the outer cylinder 2 and the inner cylinder 3 are circular in section. Both ends of the outer cylinder 2 and the inner cylinder 3 in the axial dir...

Embodiment 2

[0048] Please combine Figure 6 , this embodiment 2 is an improved solution of embodiment 1, specifically, the base plate 1 is rotated and interspersed with a rotating shaft 19 . One end of the rotating shaft 19 is fixedly connected with the wheel body of the driving gear 10 , and the other end penetrates the base plate 1 and penetrates into the liquid storage tank 20 , and is fixed with a helical stirring rod 21 .

[0049] When driving gear 10 rotates, it can drive rotating shaft 19 to rotate synchronously. Check 4 for polished use.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap