Device for punching pipe orifice of plastic pipe

A plastic pipe, punching technology, applied in metal processing and other directions, can solve the problems of low punching efficiency and easy hand injury, and achieve the effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

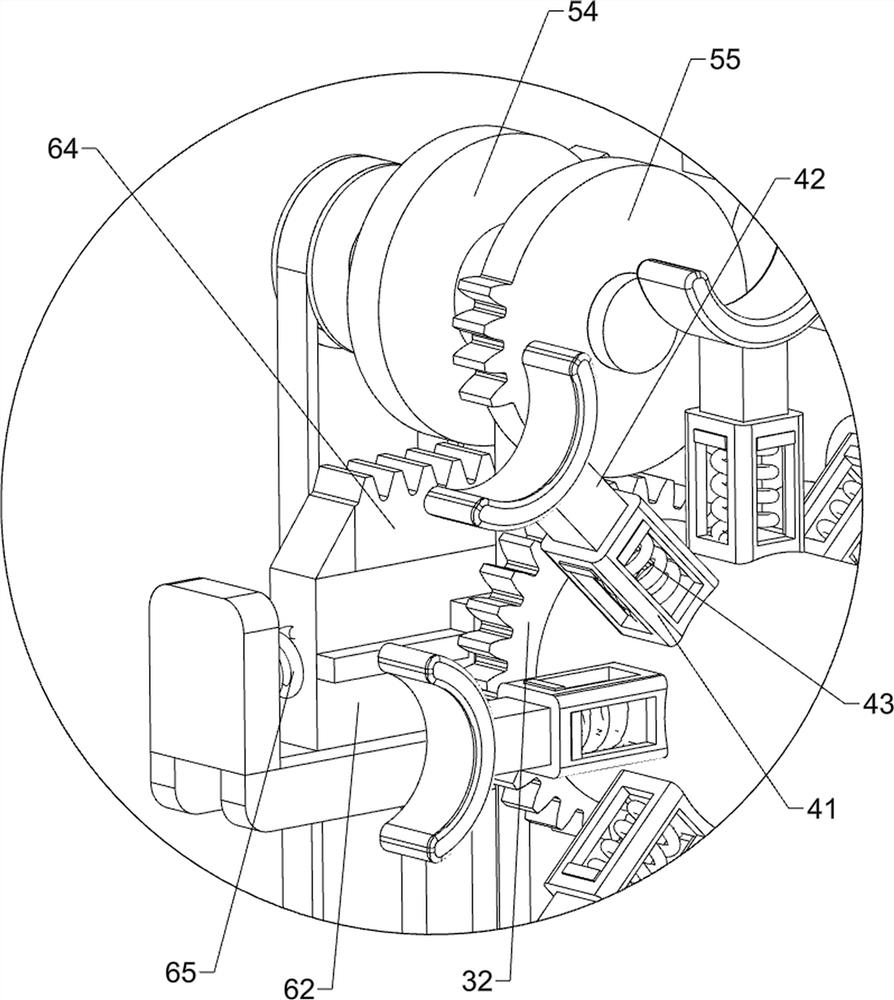

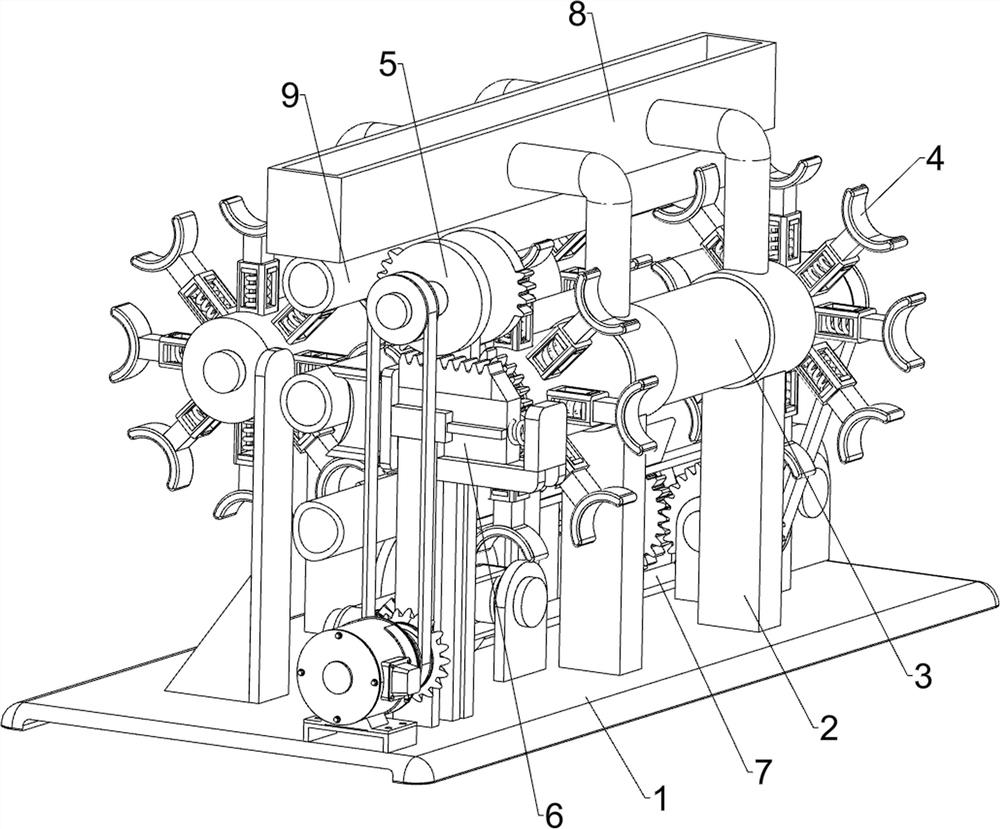

[0025] A device for punching the mouth of plastic pipes, such as Figure 1-4 As shown, it includes a base plate 1, a support frame 2, a rotating mechanism 3, a clamping mechanism 4, a driving mechanism 5 and a punching mechanism 6. Two support frames 2 are connected symmetrically on the front and rear sides of the top of the base plate 1, and the base plate 1 A rotating mechanism 3 is installed between the supporting frame 2, a clamping mechanism 4 is installed on the rotating mechanism 3, a driving mechanism 5 is installed on the top of the bottom plate 1, the driving mechanism 5 is connected to the rotating mechanism 3, and a punching mechanism is installed on the top of the bottom plate 1 6. The punching mechanism 6 is in transmission connection with the driving mechanism 5 .

[0026] The rotating mechanism 3 includes a rotating shaft rod 31, a transmission gear 32, a first transmission belt group 33, a first mounting base 34 and a driving gear 35, and a rotating shaft rod ...

Embodiment 2

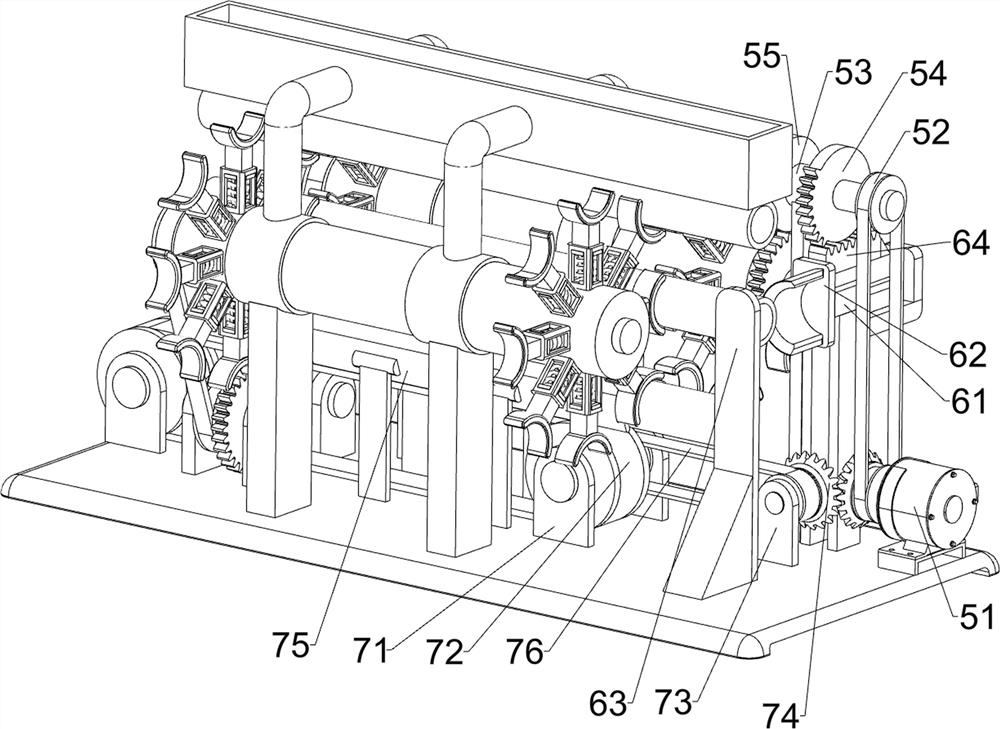

[0032] On the basis of Example 1, such as image 3As shown, a transmission mechanism 7 is also included, and the transmission mechanism 7 includes a second mounting seat 71, a conveyor belt group 72, a third mounting seat 73, a bevel gear 74 group, a limit plate 75 and a third transmission belt group 76, and the bottom plate 1. The left and right sides of the top are connected with the second mounting base 71, and the conveyor belt group 72 is rotatably connected between the two second mounting bases 71. The left side of the bottom plate 1 is connected with the third mounting base 73. The third mounting base 73 Located on the left side of the second mount 71 on the left side, the third mount 73 is rotatably connected with a bevel gear 74, and the output shaft of the servo motor 51 is also connected with a bevel gear 74, and the two bevel gears 74 mesh with each other. A third drive belt set 76 is connected between the drive shaft of the bevel gear 74 on the seat 73 and the dri...

Embodiment 3

[0035] On the basis of Example 2, such as figure 1 As shown, it also includes a pipe feed position calibration frame 8, and the pipe feed position calibration frame 8 is connected between the tops of the four support frames 2.

[0036] The plastic pipe 9 can be put into the pipe feed position calibration frame 8, and the plastic pipe 9 falls on the clamp arm 42 through the pipe feed position calibration frame 8, so that the plastic pipe 9 can be adjusted by the pipe feed position calibration frame 8. The position is calibrated, thereby being able to facilitate punching the mouth of the plastic pipe 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com