Preparation method of 2, 5-diacylfuran compound

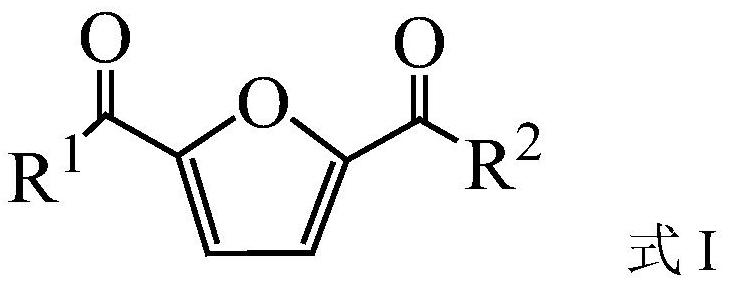

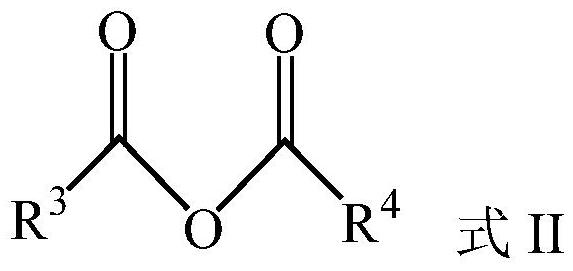

A technology for diacylfuran and compound, which is applied in the field of preparation of 2,5-diacylfuran compounds, can solve the problems of difficulty in large-scale industrial application, complex synthesis route, low total yield and the like, and achieves simple and efficient preparation method, The effect of high purity and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

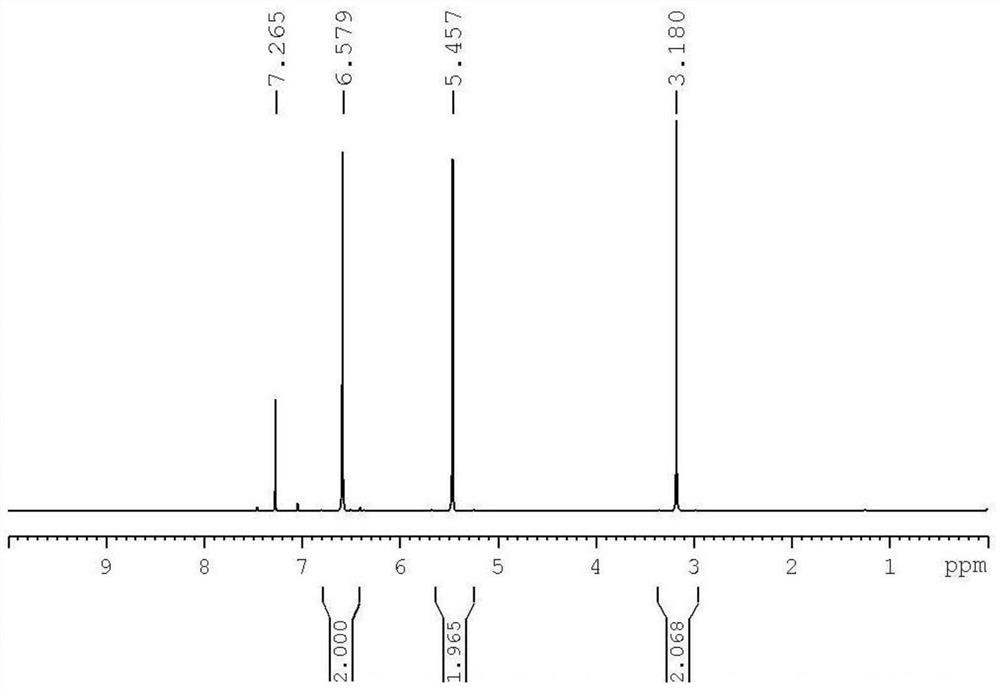

[0064] In a 500ml reactor, add 68.0g furan, 19.6g maleic anhydride, 20ml dichloromethane, react at 100°C for 1h, cool and crystallize, and dry to obtain 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2 .1] Hept-5-ene monomer, the product is white crystal, the yield is 90%. through 1 H-NMR (400MHz, CDCl 3 ) test, CH and 2H on the ring have three peaks, which are respectively δ (3.18, 5.46, 6.58).

[0065] Take 16.6g of 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2.1]hept-5-ene monomer and put it into a 250ml reactor, add 102.6g of chloroacetic anhydride, and react with 0.025mol concentrated nitric acid at 200°C 0.5h, after the reaction was completed, it was lowered to room temperature, and chloroacetic anhydride was distilled off under reduced pressure, and sublimated to obtain white crystal 2,5-dichloroacetylfuran, with a yield of 93%, as measured by liquid phase mass spectrometry (LC-MS). Molecular weight 221.0, 1 H-NMR (400MHz, CDCl 3 ) test, CH on the furan ring, 2H, δ (7.24)...

Embodiment 3

[0067] In a 500ml reactor, add 68.0g furan, 9.8g maleic anhydride, 10ml chloroform, react at 70°C for 2h, cool and crystallize, and dry to obtain 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2 .1] Hept-5-ene monomer, the product is white crystal, the yield is 96%. through 1 H-NMR (400MHz, CDCl 3 ) test, CH and 2H on the ring have three peaks, which are respectively δ (3.18, 5.46, 6.58).

[0068] Take 8.3g of 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2.1]hept-5-ene monomer and add it to a 250ml reactor, add 57.8g trifluoroacetic anhydride, 0.005mol concentrated hydrochloric acid at 160°C Reacted for 6h, after the reaction was completed, it was lowered to room temperature, trifluoroacetic anhydride was distilled off under reduced pressure, and white crystal 2,5-bis-(trifluoroacetyl)furan was obtained by sublimation, with a yield of 88%, liquid phase mass spectrometry (LC -MS) records molecular weight 260.1, 1 H-NMR (400MHz, CDCl 3 ) test, CH on the furan ring, 2H, δ (8.14).

Embodiment 4

[0070] In a 500ml reactor, add 68.0g of furan, 24.5g of maleic anhydride, 60ml of petroleum ether, react at 30°C for 6h, crystallize out, and dry to obtain 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2.1 ]hept-5-ene monomer, the product is a white crystal, and the yield is 92%. through 1 H-NMR (400MHz, CDCl 3 ) test, CH and 2H on the ring have three peaks, which are respectively δ (3.18, 5.46, 6.58).

[0071] Take 16.6g of 2,3-dicarboxylic anhydride-7-oxabicyclo[2.2.1]hept-5-ene monomer and put it into a 100ml reactor, add 15.5g of heptafluorobutyric anhydride, 0.005mol concentrated phosphoric acid at 100°C After 12 hours of reaction, after the reaction was completed, it was lowered to room temperature, and heptafluorobutyric anhydride was distilled off under reduced pressure, and crystal 2,5-bis-(heptafluorobutyryl) furan was obtained by sublimation, with a yield of 83%, liquid chromatography mass spectrometry (LC- MS) records molecular weight 460.1, 1 H-NMR (400MHz, CDCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com