Net stretching device and net stretching method

A pre-alignment and die-striping technology, applied in the fields of vacuum evaporation plating, coating, electro-solid device, etc. Efficiency, improve the precision of the net, and reduce the cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

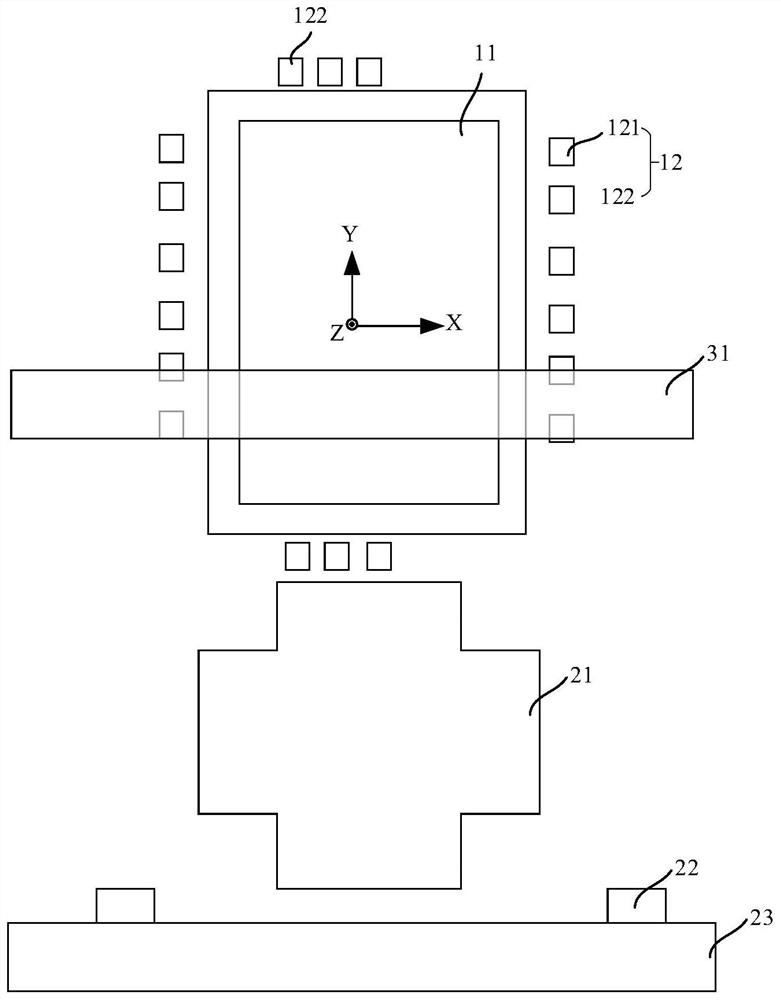

[0031] Such as figure 1 As shown, the present embodiment provides a netting device, including:

[0032] The stretching module includes a carrying platform 11 and a clamping unit 12, the carrying platform 11 is used to carry the support frame, and the clamping unit 12 is used to complete the stretching of the metal mask strips in the X direction and the Y direction;

[0033] The pre-alignment module includes a pre-alignment stage 21 and a detection unit 22, the pre-alignment stage 21 provides a carrying space for the metal mask strips in the X direction and the Y direction, and the detection unit 22 detects the metal mask strips The alignment mark on is used to correct the position of the metal mask strip relative to the pre-alignment stage 21;

[0034] The transfer module is used to pick up the metal mask strip and transfer the metal mask strip to the support frame.

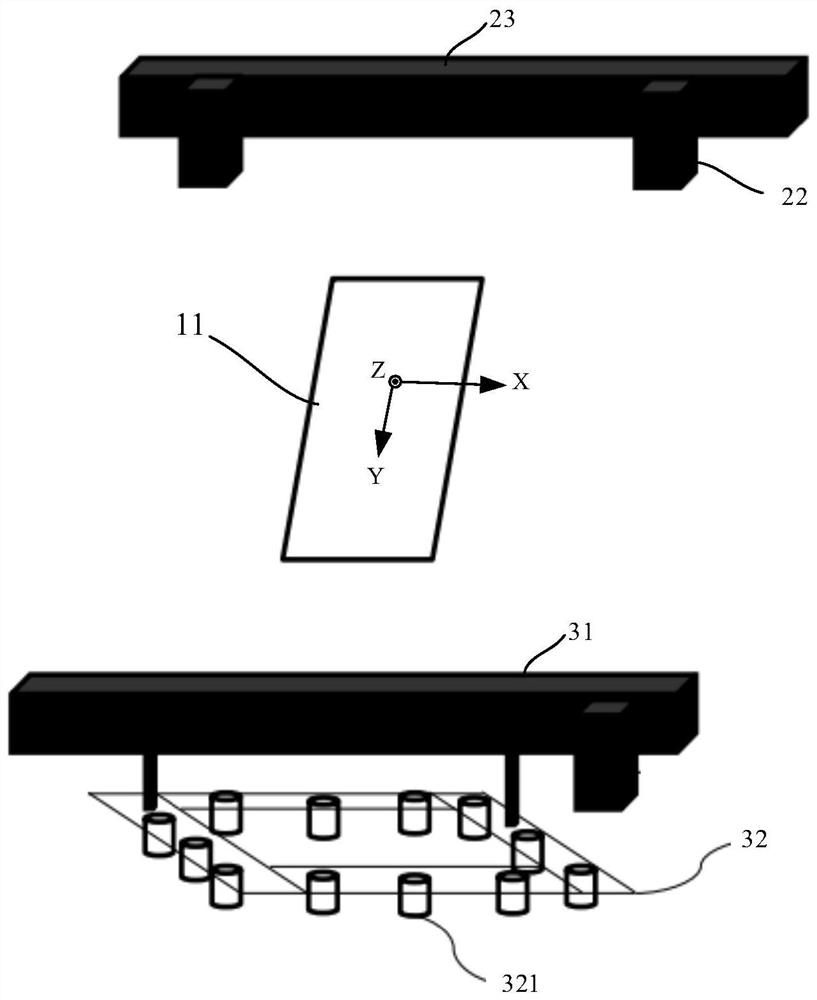

[0035] Specifically, see figure 1 and figure 2 , the support frame is arranged on the carrier platform 11...

Embodiment 2

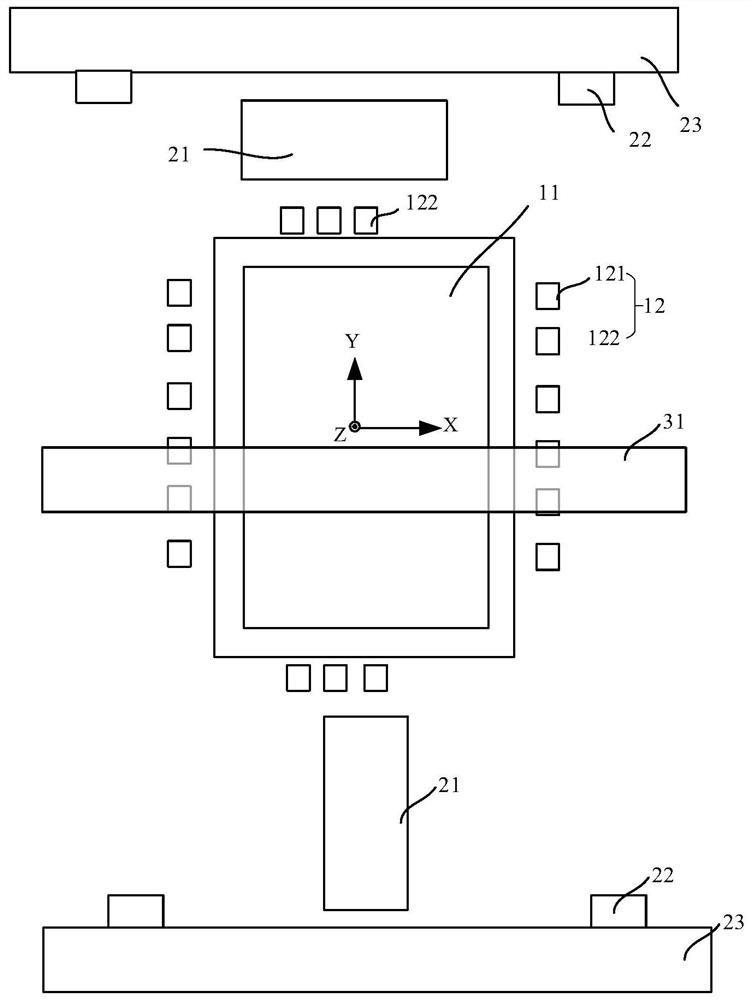

[0044] Such as image 3 As shown, the difference from Embodiment 1 is that in this embodiment, there are two pre-alignment stations 21, and the two pre-alignment stations 21 are respectively located on opposite sides of the stretching module, one of which The pre-alignment stage 21 extends along the X direction, and the other pre-alignment stage 21 extends along the Y direction. The pre-alignment stage 21 extending along the X direction provides a carrying space for the metal mask strips in the X direction, and the pre-alignment stage 21 extending along the Y direction provides a carrying space for the metal mask strips in the Y direction, that is, along the X direction The pre-alignment stage 21 extending in the direction is used for placing the metal mask strips in the X direction, and the pre-alignment stage 21 extending in the Y direction is used for placing the metal mask strips in the Y direction.

[0045] Further, the pre-alignment module also has two first gantry fram...

Embodiment 3

[0048] Such as Figure 4 As shown, this embodiment provides the use of Figure 1-Figure 3 The method for stretching the net shown by the net stretching device includes:

[0049] Step S1: placing the metal mask strip on the pre-alignment stage along its stretching direction;

[0050] Step S2: Correcting the position of the metal mask strip relative to the pre-alignment stage by detecting the alignment mark on the metal mask strip;

[0051] Step S3: Transfer the metal mask strips to the support frame and stretch the net.

[0052] Specifically, the preparation of the metal mask usually requires the netting of FMM metal mask strips, side stick metal mask strips, cover metal mask strips and support metal mask strips, wherein the FMM metal mask strips, side stick metal mask strips The stretching direction of the mold strip and the cover metal mask strip is the X direction, and the stretching direction of the support metal mask strip is the Y direction.

[0053] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com