High-pressure wave water tank device

A water tank and wave technology, applied in measurement devices, hydraulic models, instruments, etc., can solve the problem of insufficient simulation of large storm waves, and achieve the effects of simple structure, low cost and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

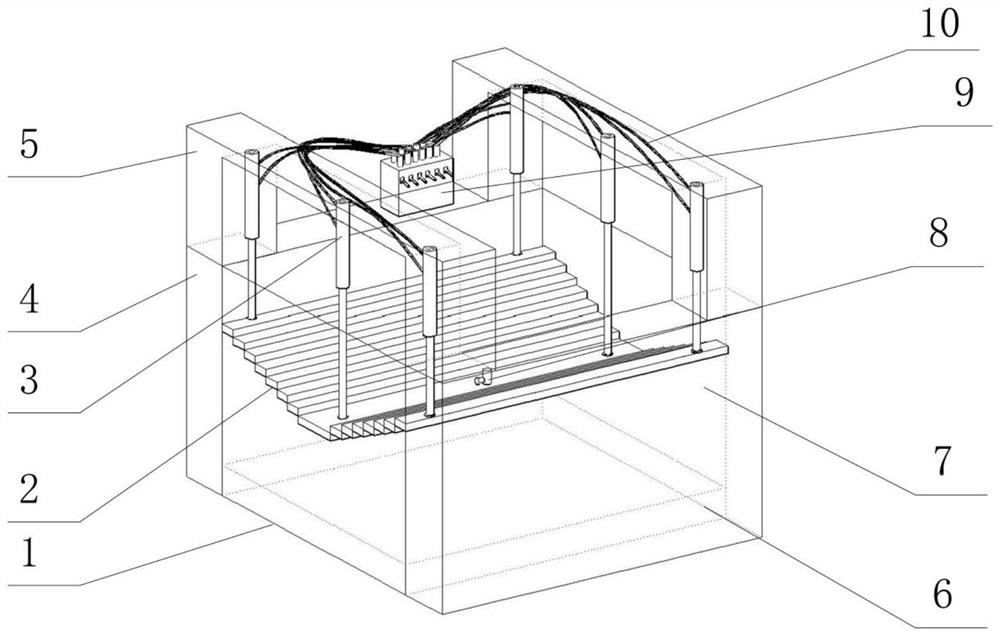

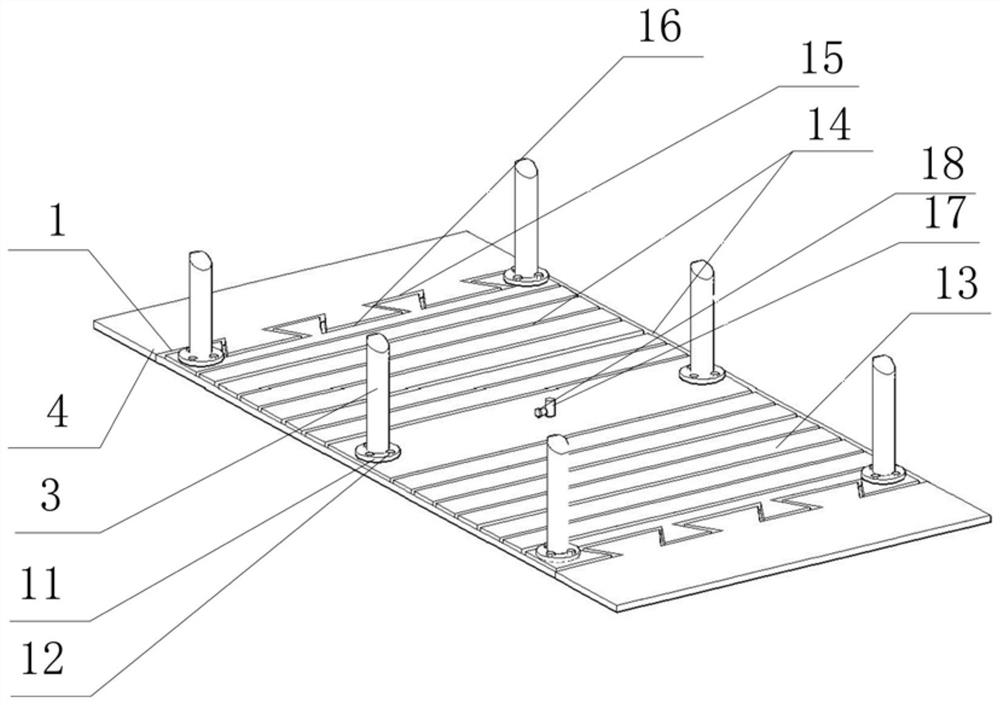

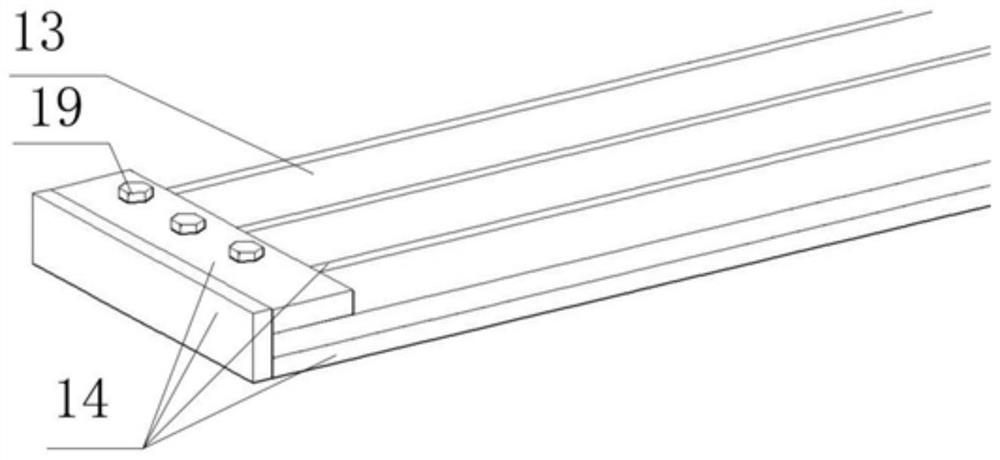

[0041] Such as Figure 1 to Figure 4 As shown, a high-pressure wave tank device includes a civil foundation 4, a wave tank 1, a wave piston 2, an I-beam 5, a hydraulic rod 3, a hydraulic pump 9, and the like.

[0042] There are two civil foundations 4 arranged symmetrically. The wave-making water tank 1 is arranged between the two civil foundations 4, and the shape of the inner wall of the civil foundation 4 is consistent with the shape of the outer walls of the left and right sides of the wave-making water tank 1, so that the wave-making water tank 1 can be vertically placed into the two civil foundations 4 and closely attached to the two civil foundations 4, the wave-making tank 1 and the civil foundation 4 jointly bear the inward movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com