Water-saving pressure type pure flat closestool base

A pressure type, pure flat technology, applied in water supply equipment, flushing toilets, buildings, etc., can solve the problems that the flushing effect cannot be significantly improved, the wall of the urinal is difficult to fully flush, and the wall of the urinal is no longer smooth, so as to avoid Effects of dirt retention, improved flushing effect, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

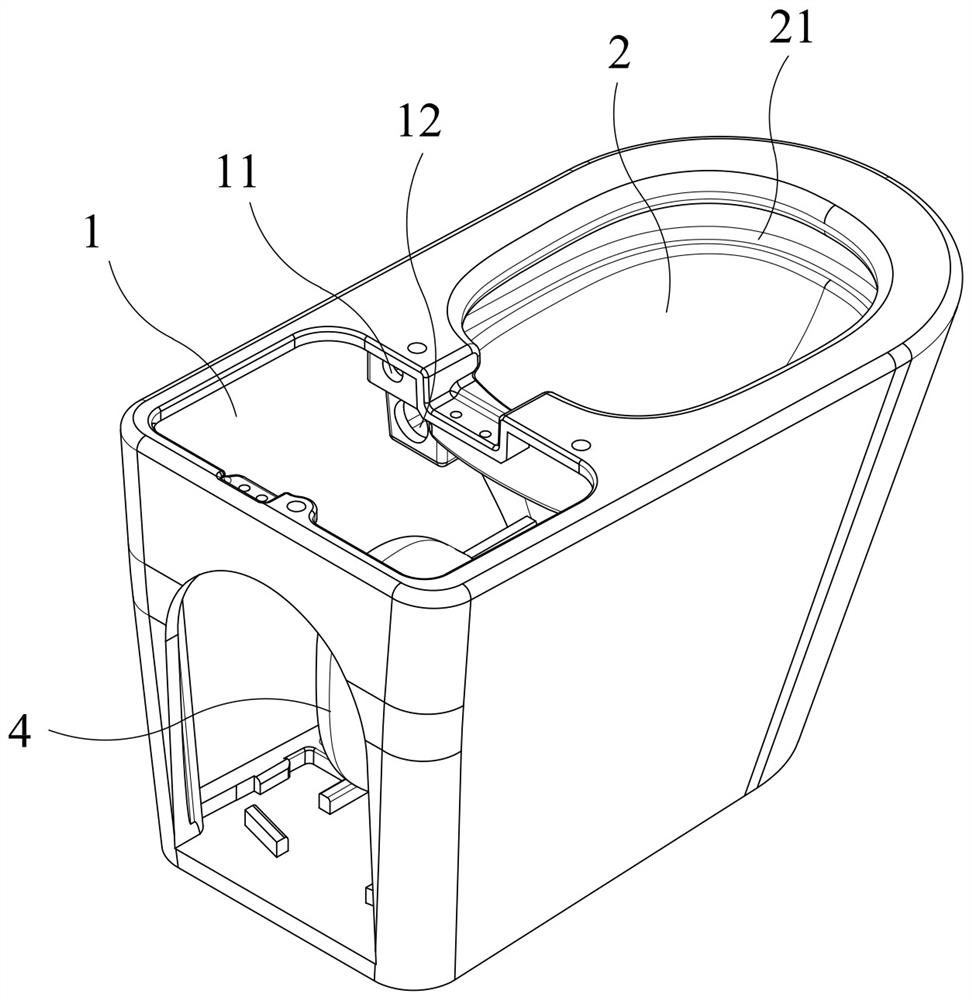

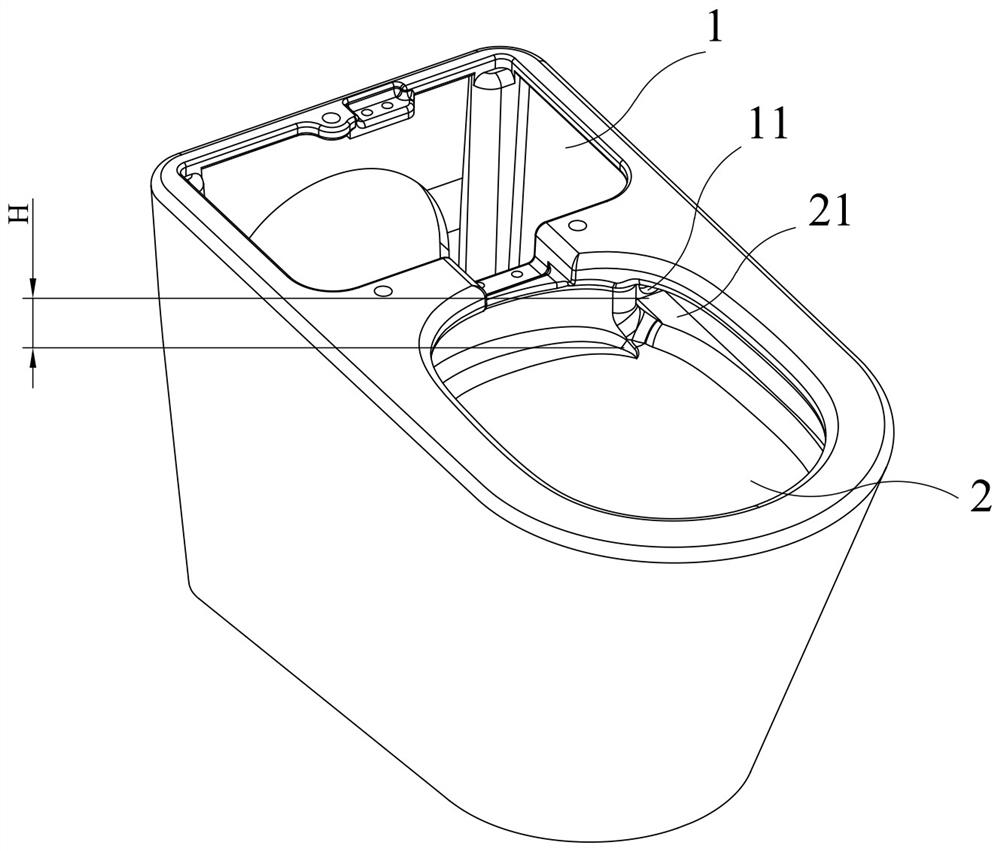

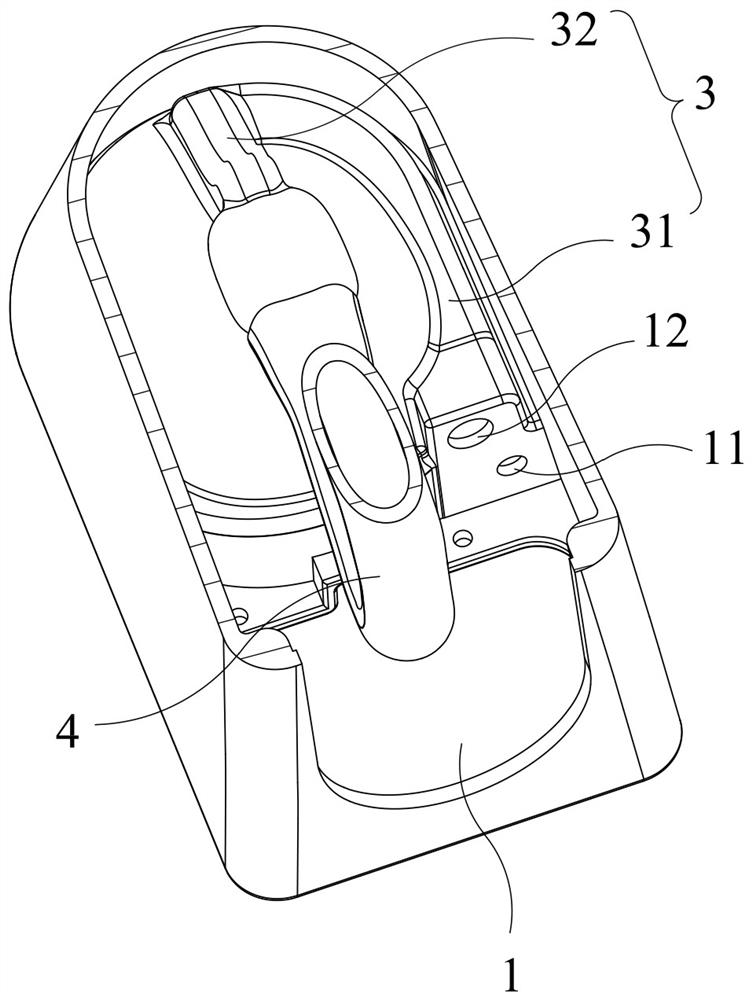

[0026] The present invention is a water-saving pressure-type flat toilet base, which includes an accommodating cavity 1 and a urinal 2 arranged front and back, as well as a main flushing pipeline 3 and a sewage discharge pipeline 4 .

[0027] The accommodating cavity 1 is provided with punching ring holes 11 and main punching holes 12;

[0028] The top of the urinal 2 is provided with a water-guiding step 21, and the water-guiding step 21 is arranged in a ring along the wall of the urinal 2 and its height gradually decreases, and its starting end is set opposite to the flushing ring hole 11; the bottom of the urinal 2 is provided with Sewage outlet 22;

[0029] The main flushing pipe 3 is arranged around the outer periphery of the urinal 2, and includes a horizontal delay section 31 and an obliquely arranged d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com