Sliding block

A slider and integrated technology, applied in the field of guide rails, can solve the problems of high friction coefficient of sliders, difficult to guarantee accuracy, easy wear and other problems, and achieve the effect of strong rigidity, convenient use and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The applicant first explains here that in the entire specification, including the embodiments described below and the claims of the claims, "upper", "lower", "left", "right", "front", "rear" , "Top", "Bottom", "Inner", "Outer" and other directional nouns are all based on the direction in the attached drawing. Secondly, the horizontal position of the right-angled side of the T-shaped slot is the bottom surface of the T-shaped slot. , in the embodiments and drawings to be described below, the same component numbers represent the same or similar components or their structural features.

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

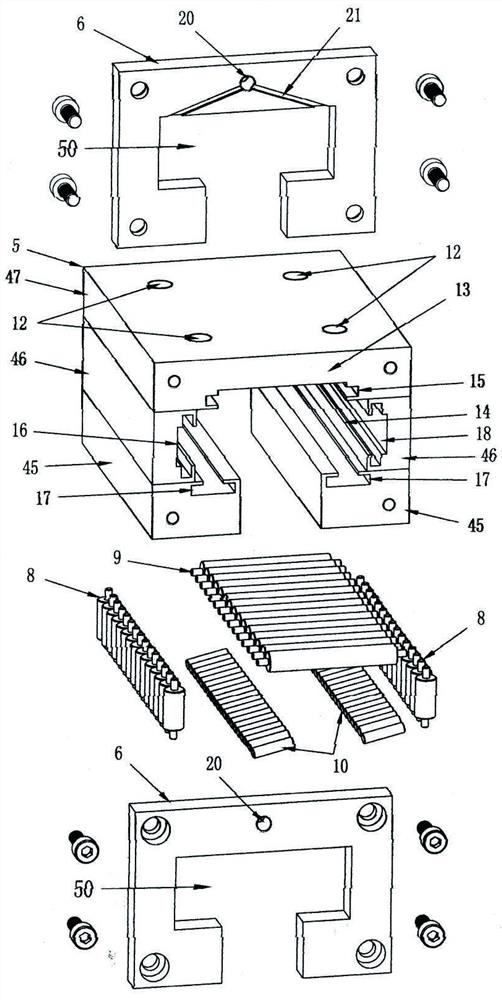

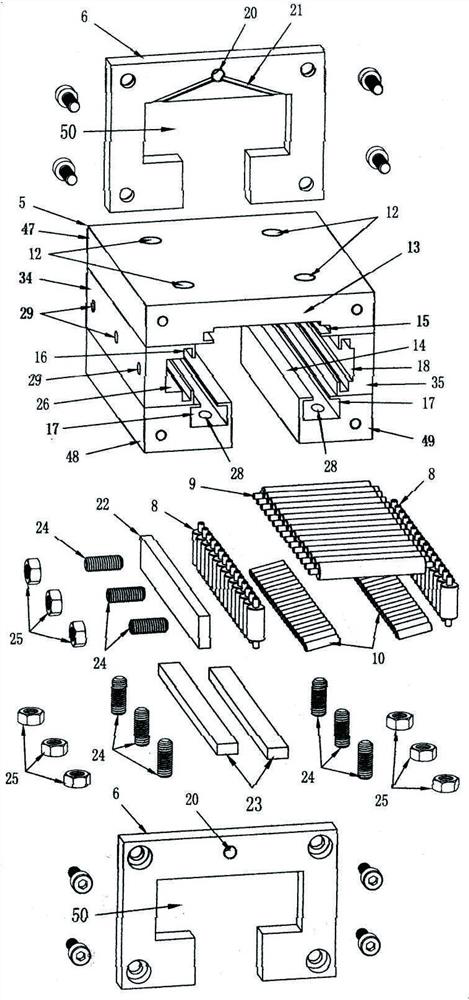

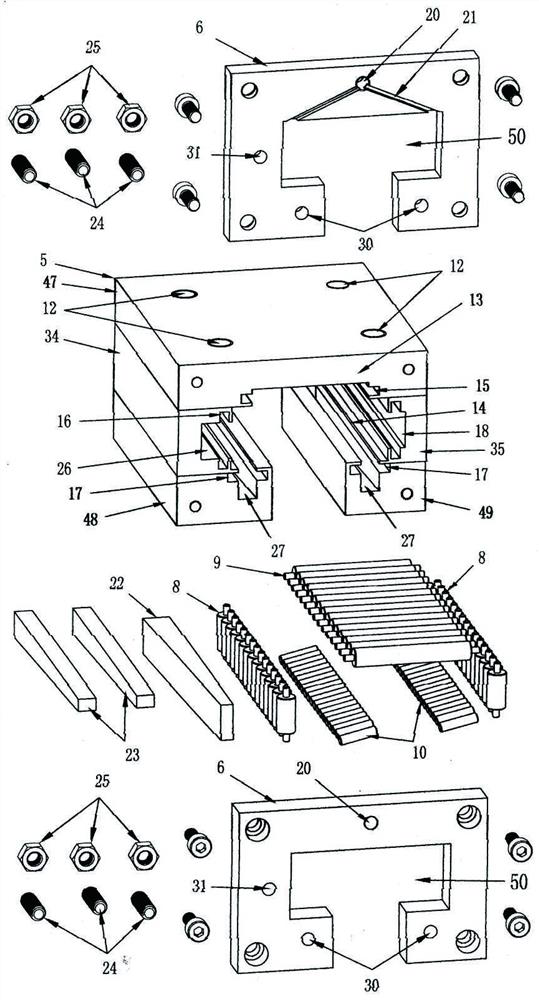

[0034] figure 1A slider is shown, which is characterized in that it includes a slider body 5, and a slider installation hole 12 is provided on the top surface of the slider body; the front surface 13 of the slider body is provided along the length direction There ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com