Three-point adjustment method for adjusting valve with electric valve positioner

A technology of valve positioner and regulating valve, which is applied in the direction of valve details, valve operation/release device, valve device, etc. It can solve the problems of long time-consuming adjustment, difficulty in finding the zero point, and large error in the confirmation process of starting point, etc., to achieve High accuracy, simple adjustment process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

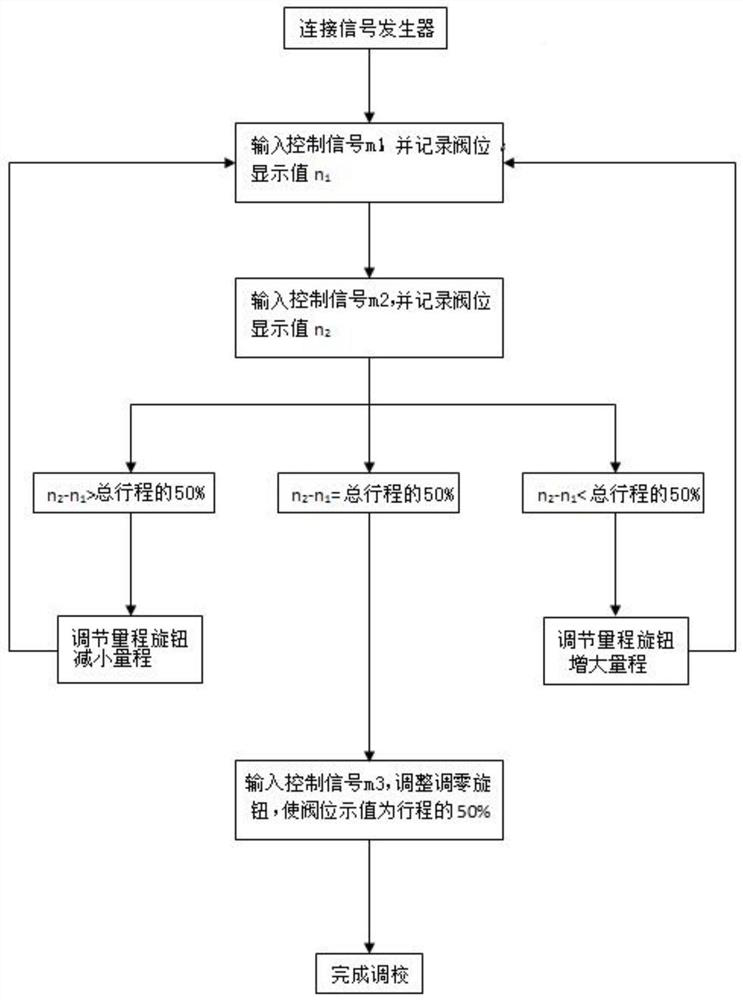

[0022] like figure 1 As shown, a three-point adjustment method for a regulating valve with an electric valve positioner includes the following steps:

[0023] 1) Connect the regulating valve to be calibrated to the signal generator;

[0024] 2) In the regulating valve to be calibrated, input the control signal m 1 , record the control signal m 1 Corresponding valve position display value n 1 ;

[0025] 3) In the regulating valve to be calibrated, input the control signal m 2 , record the control signal m 2 Corresponding valve position display value n 2 ;

[0026] 4) Calculate n 2 and n 1 Compare the difference with 50% of the total stroke of the calibrated regulating valve; adjust the range knob according to the comparison result until the difference is equal to 50% of the total stroke of the calibrated regulating valve;

[0027] 5) Input control signal m 3 , adjust the valve position display value to the position of 50% of the total stroke of the calibrated regulat...

Embodiment 2

[0030] On the basis of Example 1, further, the control signal m 1 The range is: 4mA≤m 1 ≤12mA. Limit control signal m 1 range, the purpose is for the next calibration point, that is, the control signal m 2 The value of , the range design is reasonable.

[0031] Further, the control signal m 2 for m 1 +8. The reason m 2 value m 1 +8 is because the general output signal range is 4mA-20mA, that is, the total output signal range is (20-4)mA, that is, 16mA, the purpose is to achieve m 2 -m 1 / 16 is 50% of the total range of the output signal, and finally realize the one-to-one correspondence between the interval value of the two output signals and the difference between the two indications corresponding to the stroke indicator of the regulating valve actuator and the total stroke of the actuator.

[0032] Further, the step 2) input control signal m 1 , when the valve position display value n 1 When it is greater than 50% of the total stroke of the regulating valve to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com