Small-angle LED lens with triple calculus structure and implementation method of small-angle LED lens

A technology of LED lens and implementation method, which is applied in the parts of lighting devices, semiconductor devices of light-emitting elements, lighting devices, etc., and can solve the problem that the small angle of 10° cannot be truly achieved, the optical efficiency of the whole light is low, and the light spot effect is poor. etc. to achieve the effect of high central light intensity, small angle and soft spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

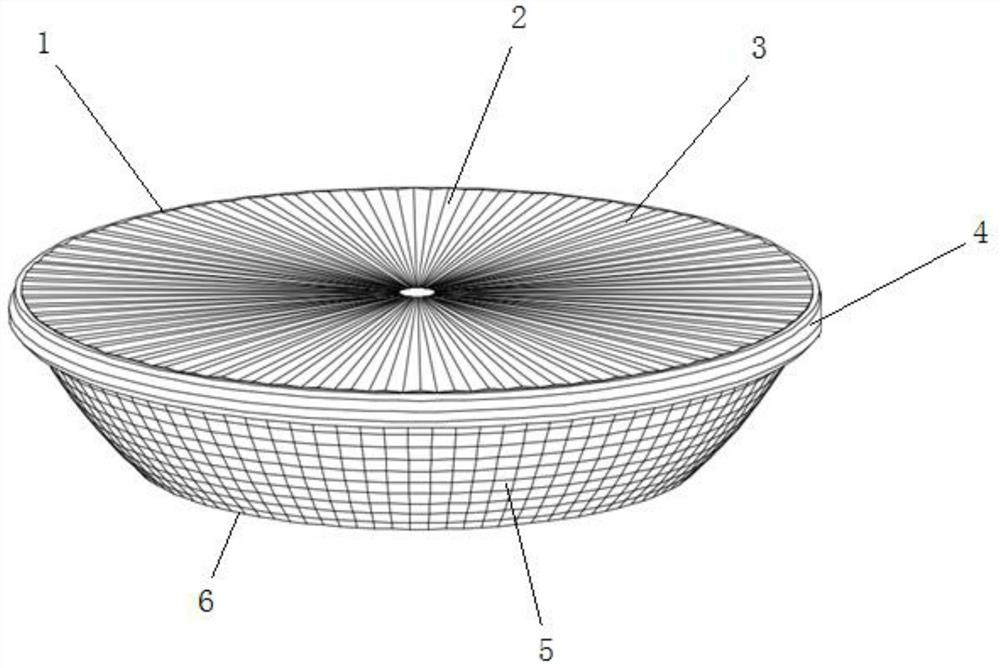

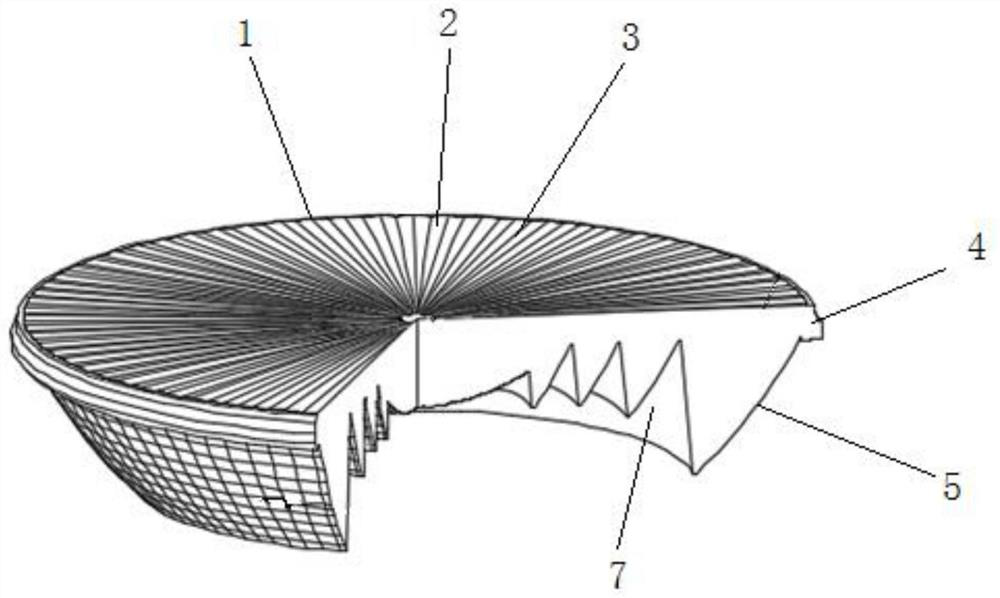

[0037] see Figure 1-5 , the present invention provides the following technical solutions: a small-angle LED lens with a triple calculus structure, including a lens body 1, a dense concave-convex structure 3 is provided on the light-emitting surface 2 of the lens body 1, and a light inlet 6 of the lens body 1 There are several layers of light-contracting cups 7 from outside to inside, and total reflection sheets 5 are provided on the side walls of several light-contracting cups 7 .

[0038] Specifically, the lens body 1 is a cone-shaped structure.

[0039] Specifically, the side of the lens body 1 with a larger diameter is the light exit surface 2 , and the side of the lens body 1 with a smaller diameter is the light inlet 6 .

[0040] Specifically, the dense concave-convex structure 3 is radially arranged on the light-emitting surface 2, and the cross-section of the concave-convex structure 3 is a triangular structure.

[0041] By adopting the above technical solutions, suc...

Embodiment 2

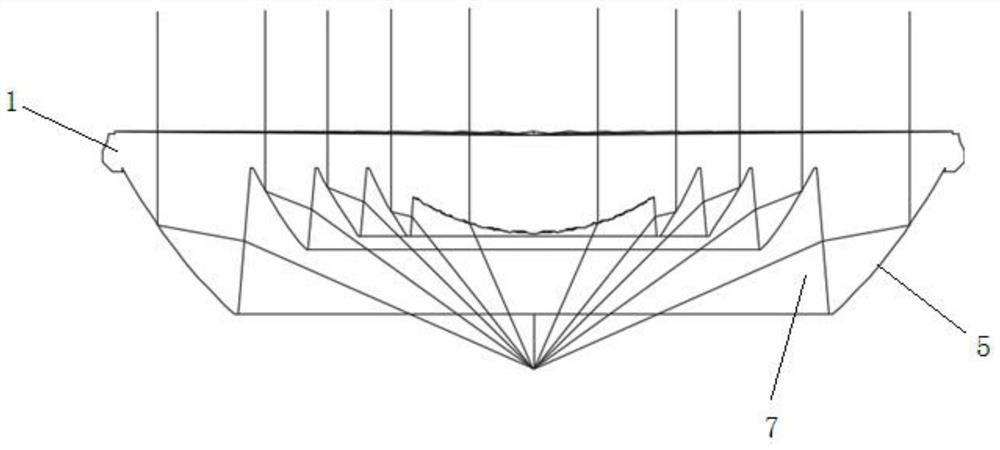

[0044] The difference between this embodiment and Embodiment 1 lies in that specifically, the depths of several light converging cups 7 decrease sequentially from outside to inside.

[0045] By adopting the above technical solutions, such as image 3 As shown, the light inlet is expanded, and the light emitted by the light source is Lambertian light, which can be included and shrunk by the light inlet of sufficient size, so that the overall optical efficiency can reach 92%. The shrunk light passes through the light inlet and is microscopically Each light beam that exists in the integral mode is differentially divided by the cup body 7, and each divided light beam first refracts through the inner wall of the corresponding cup, and after reaching the side wall, according to the law of total reflection, the light beam is irradiated in a collimated manner after the total reflection of the side wall. On the light-emitting surface, the collimated light rays formed in this way on all...

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 lies in that: specifically, the total reflection sheet 5 has an array structure of several layers.

[0048] By adopting the above technical solutions, such as Figure 4 As shown, the side walls of each layer of light converging cup 7 are differentially arrayed into a series of total reflection sheets 5, and these total reflection sheets 5 divide the light rays contracted by the cup body, and then adjust the curvature of the total reflection sheets separately, to the corresponding The segmented light is collimated and adjusted, and finally the light of each total reflection sheet is integrated, so as to achieve the effect of increasing the light intensity in the center of the spot.

[0049] Further, the realization method of the small-angle LED lens with triple calculus structure according to the present invention includes the following steps:

[0050] (1), process the light inlet 6 of the lens body 1 through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com