Rapid motor dismounting and mounting tool and dismounting and mounting method

A disassembly method and motor technology, applied in the manufacture of tools, hand-held tools, etc., can solve the problems of time-consuming and labor-intensive, potential safety hazards of moving motors, high investment costs of lifting tools, etc., to achieve rapid separation, avoid unpredictable risks, and save maintenance The effect of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

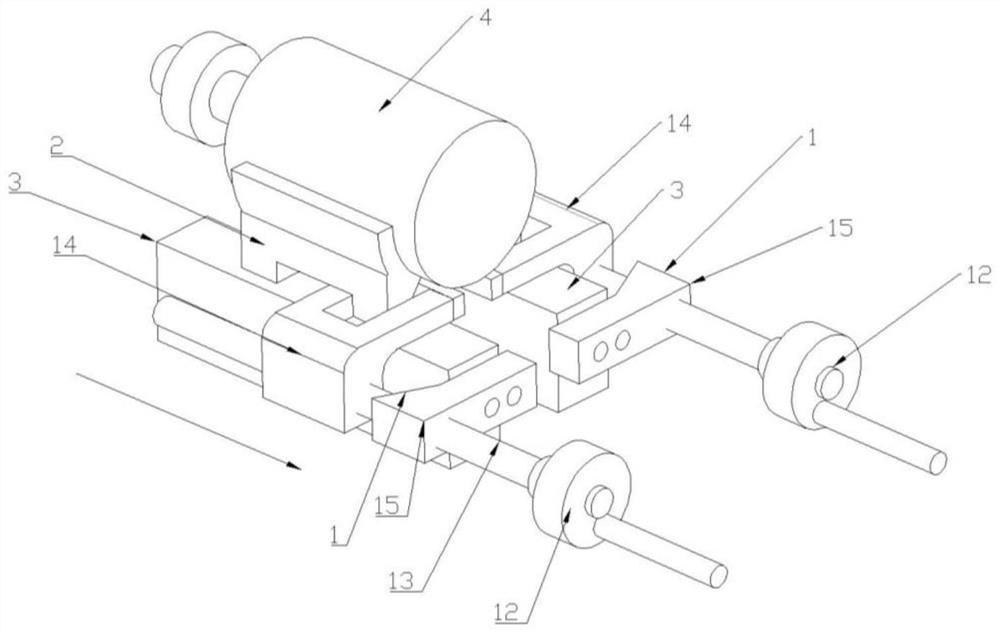

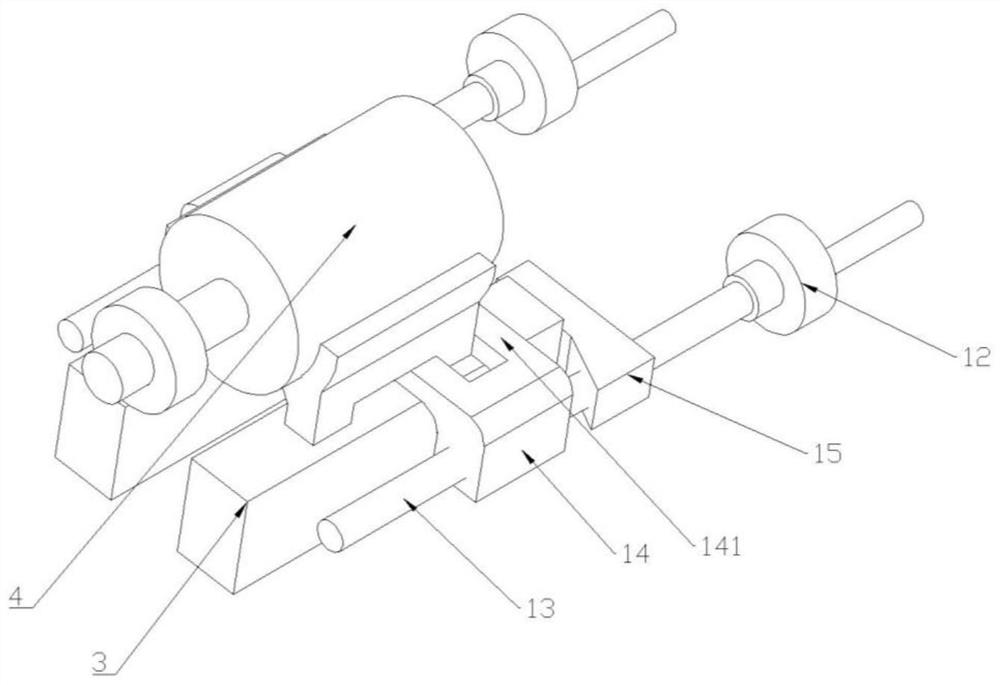

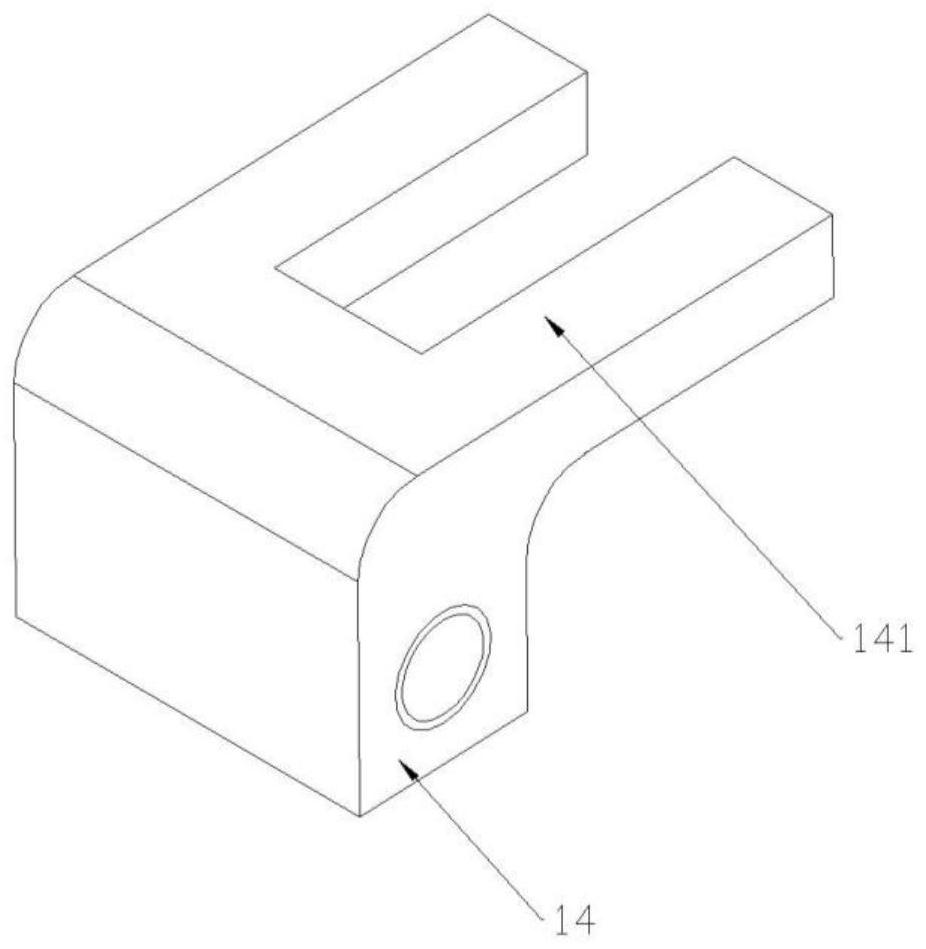

[0039] refer to Figure 1-Figure 3 , the present invention provides a quick disassembly and assembly tool for a motor, including a disassembly and assembly device 1 symmetrically arranged on both sides of the motor 4 in the axial direction. 13 drive-connected screw nut block 14 and fixed frame 15, said fixed frame 15 is provided with a transmission screw hole cooperating with screw rod 13, said screw rod 13 is connected with screw rod nut block 14 and fixed frame 15 in turn, and said screw rod The nut block 14 is provided with a clamping part 141 for clamping the motor base 2, and the driving part 12 drives the screw 13 to rotate, and drives the screw nut block 14 to move horizontally, thereby driving the motor base 2 and the motor 4 to move horizontally, realizing the in-situ separation of the motor 4 or snug connection. Such a setting can realize the rapid separation of the motor 4, especially the horizontal installation motor, without lifting the motor 4 away from the inst...

Embodiment 2

[0045] The present invention also provides a disassembly method using the above-mentioned motor quick disassembly tooling, the steps of which include:

[0046] S1: Remove the screws of the motor 4 shaft and the coupling, remove the screws connecting the motor base 2 and the motor bottom plate 3, so that the motor 4 is in a free state;

[0047] S2: symmetrically fix the two fixing frames 15 on the motor bottom plate 3;

[0048] S3: Pass the clamping parts 141 of the two screw nut blocks 14 through the gaps on both sides of the motor base 2 respectively;

[0049] S4: Pass the two screw rods 13 through the transmission screw holes of the fixed frame 15 on the corresponding side and the nut holes of the screw nut block 14 in turn;

[0050] S5: Connect the two driving parts 12 to the end of the corresponding screw rod 13 close to the fixing frame 15;

[0051] S6: Start the driving part 12 at the same time, the driving part 12 drives the screw 13 to rotate in the positive directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com