An automatic vibrating equipment for concrete in a building corner plate composite mold

A combined mold and concrete technology, which is applied in the direction of manufacturing tools and ceramic molding machines, can solve the problems of small thickness of building corner boards, low production of building corner boards, inconvenient vibration work of building corner boards, etc., to avoid column tilting, The effect of convenient vibrating work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

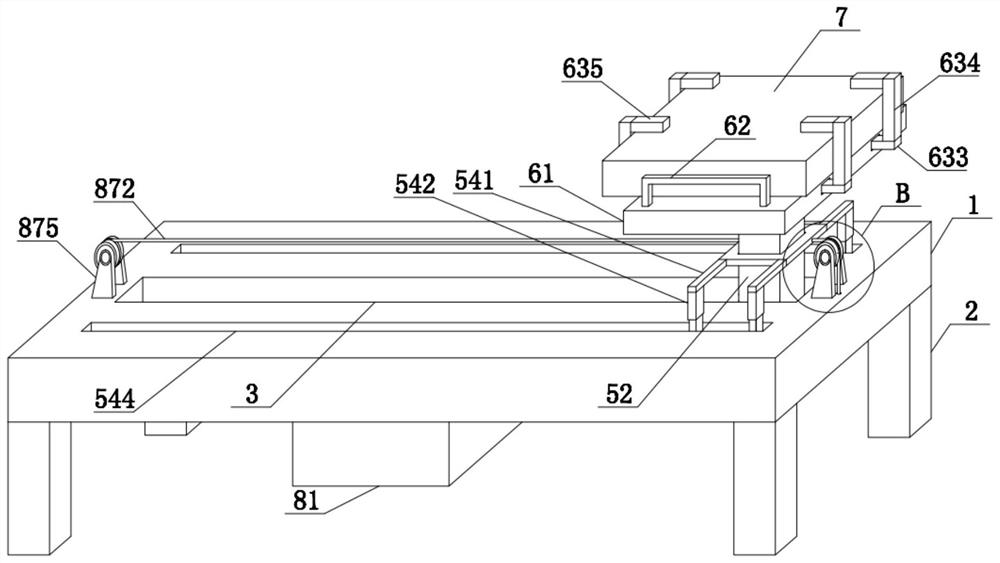

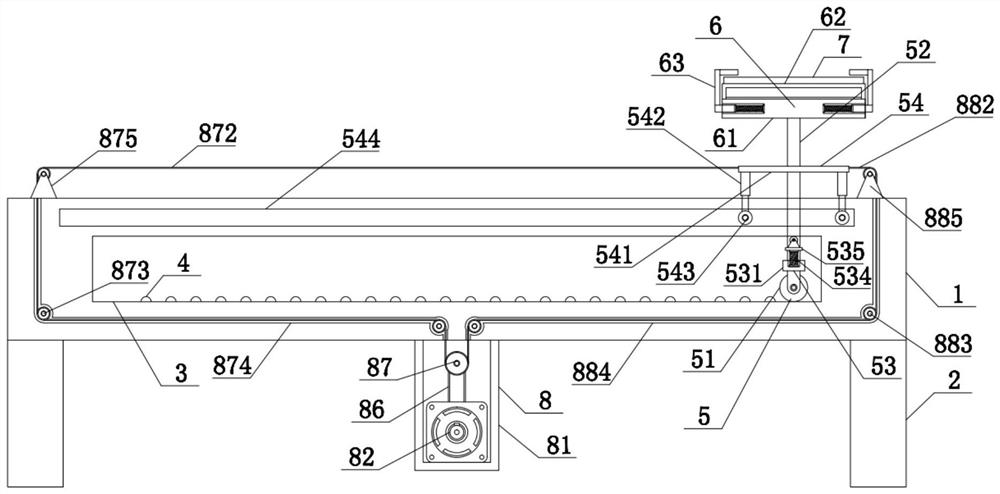

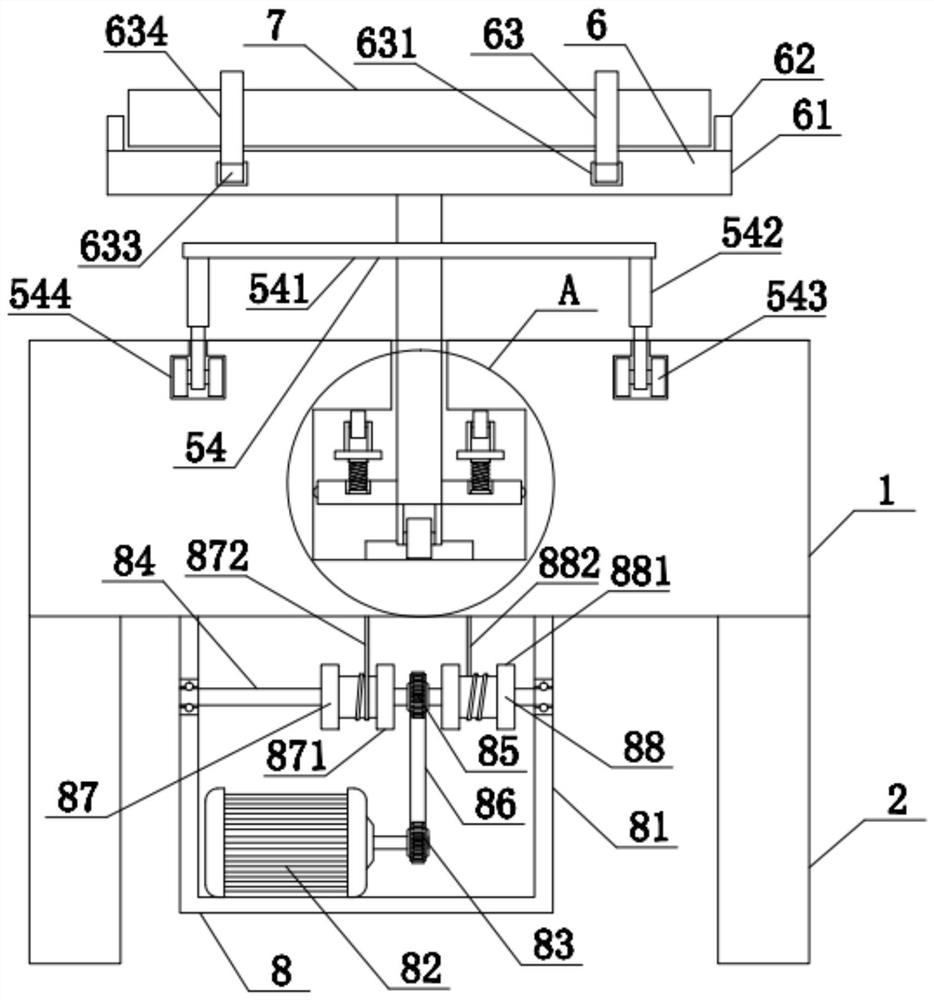

[0036] see also Figure 1-7 An automatic vibrating device for concrete in a building corner plate combined mold comprises a vibrating table 1, wherein the lower chamfers of the vibrating table 1 are fixedly connected with supporting legs 2; a first cavity 3 is arranged inside the vibrating table 1; a vibrating lug 4 is fixedly installed inside the first cavity 3; a vibrating mechanism 5 is movably connected inside the first cavity 3; a fixing rod at the upper end of the vibrating mechanism 5 is connected with a fixing mechanism 6; and a combined mold body 7 is movably connected inside the fixing mechanism 6.

[0037] The vibrating mechanism 5 includes a first roller 51, an upright post 52, a limiting assembly 53 and a positioning assembly 54, wherein the first roller 51 is rotatably connected to the inside of the first cavity 3, and the upright post 52 is fixedly installed at the upper end of the first roller 51, and the upper end of the upright post 52 penetrates through the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com