Oscillating type slurry smashing equipment for light wallboard processing

A lightweight wall panel, oscillating technology, applied in auxiliary molding equipment, manufacturing tools, ceramic molding machines, etc., can solve the problems of inconvenient use and inflexible operation, and achieve the effects of convenient operation, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

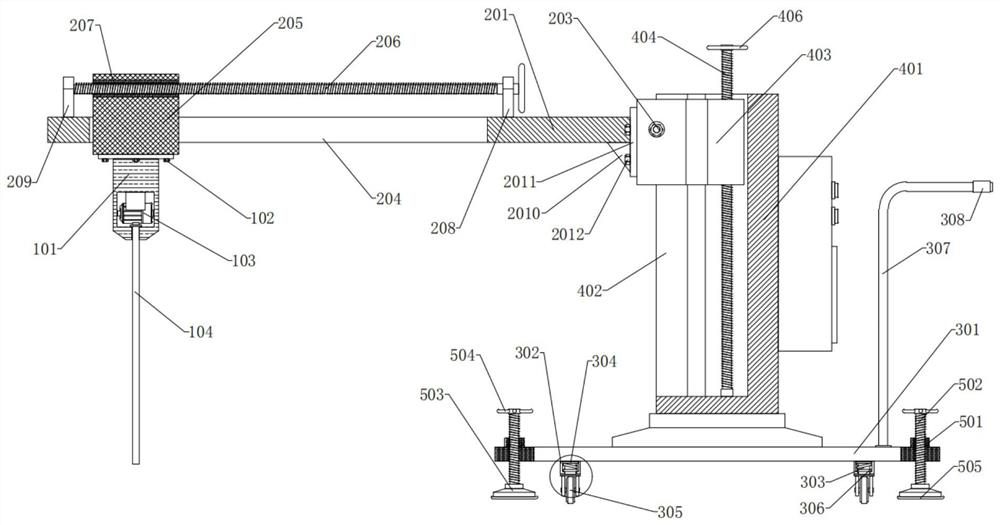

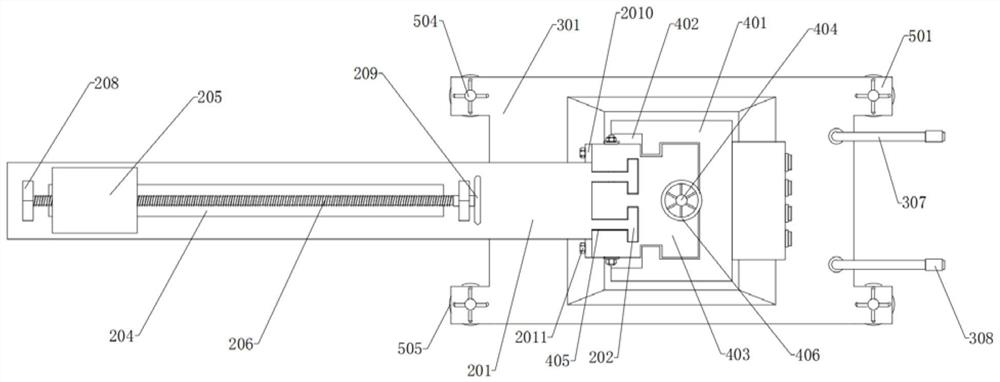

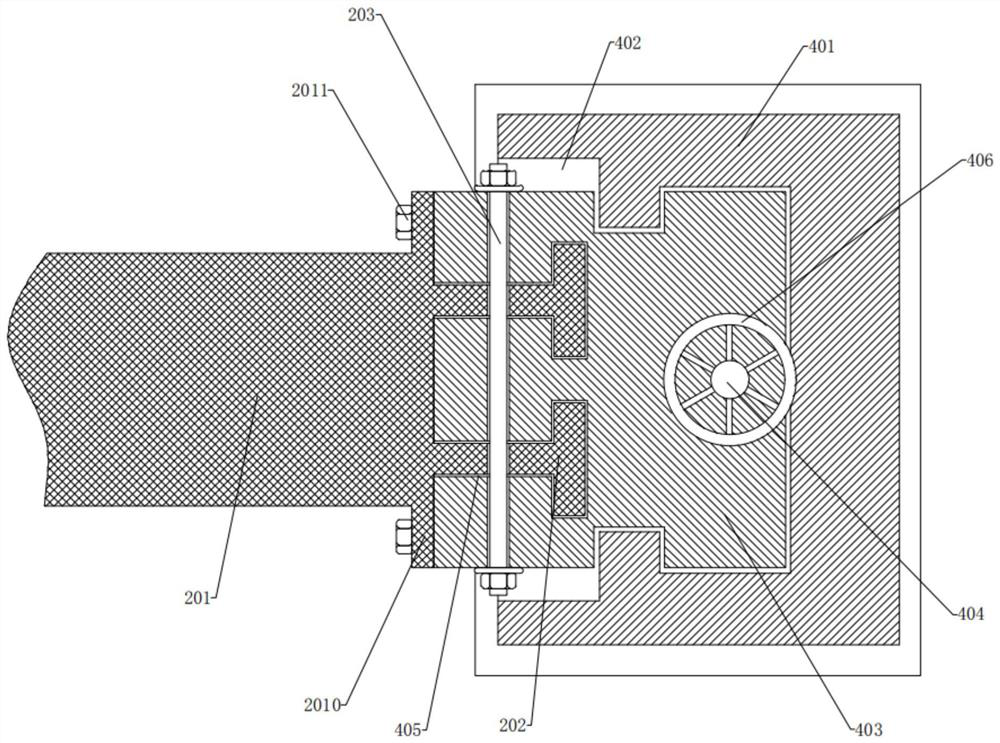

[0031] Embodiment: according to specification Figure 1-5 It can be seen that this case is an oscillating pulping equipment for light wallboard processing, including a vibrating component 1, a sliding positioning component 2 and a pushing mechanism. The vibrating component 1 is installed on the pushing mechanism through the sliding positioning component 2, and the pushing The mechanism is connected to the fixed end of the sliding positioning assembly 2, the vibrating assembly 1 is installed on the moving end of the sliding positioning assembly 2, and the pushing mechanism is composed of the supporting mobile assembly 3 at the bottom, the connecting assembly 4 installed on the supporting mobile assembly 3 and Two pairs of fixed assemblies 5 installed on both sides of the supporting mobile assembly 3 consist of two pairs of fixed assemblies 5. In the specific implementation process, the supporting mobile assembly 3 is used as the sliding device at the bottom, and is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com