A compressible material hold

A technology for cabins and materials, applied in some cabins, hulls, presses, etc. in the hull, can solve the problems of limited cabin volume and small salvage, achieve high automation, high space utilization, and improve salvage volume and loading efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

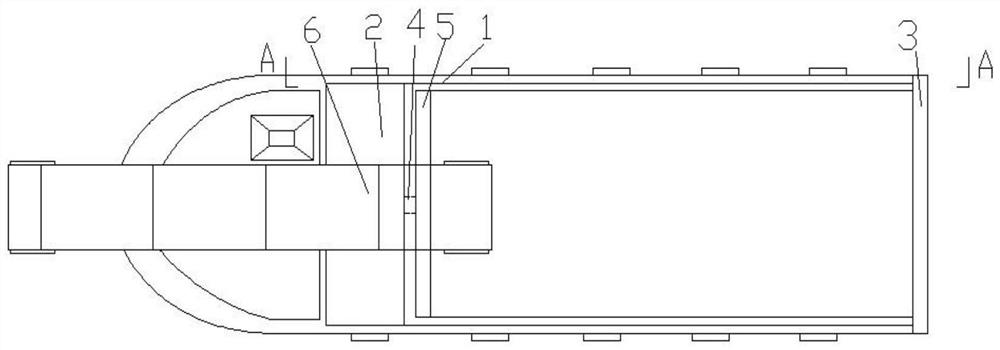

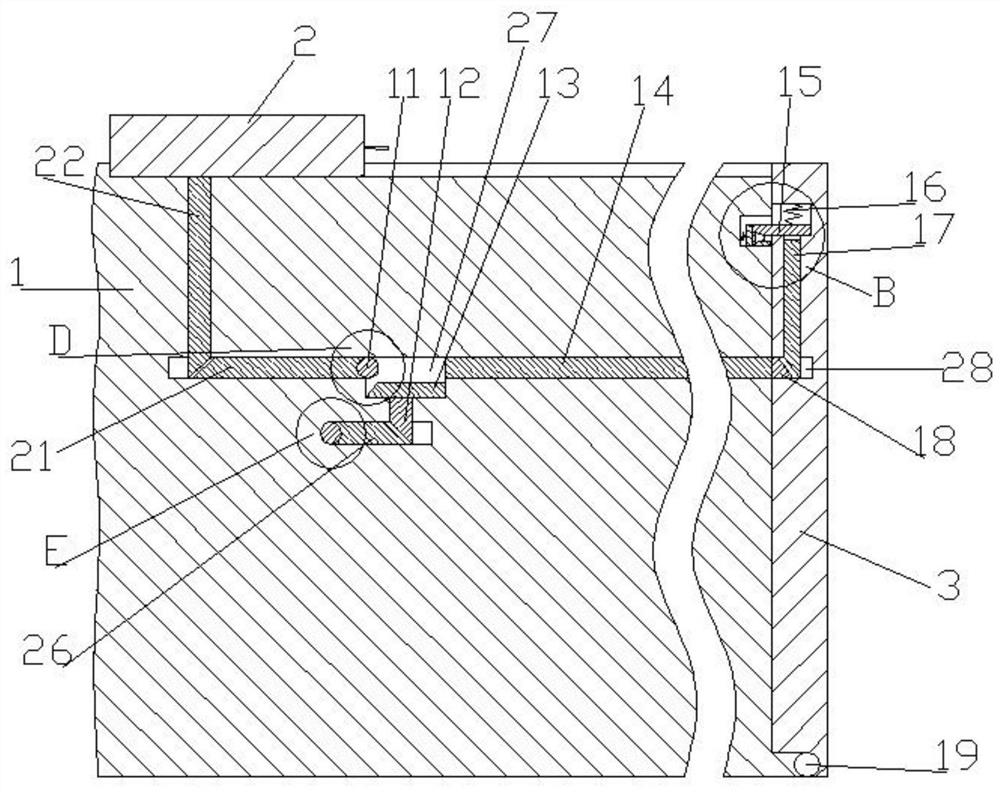

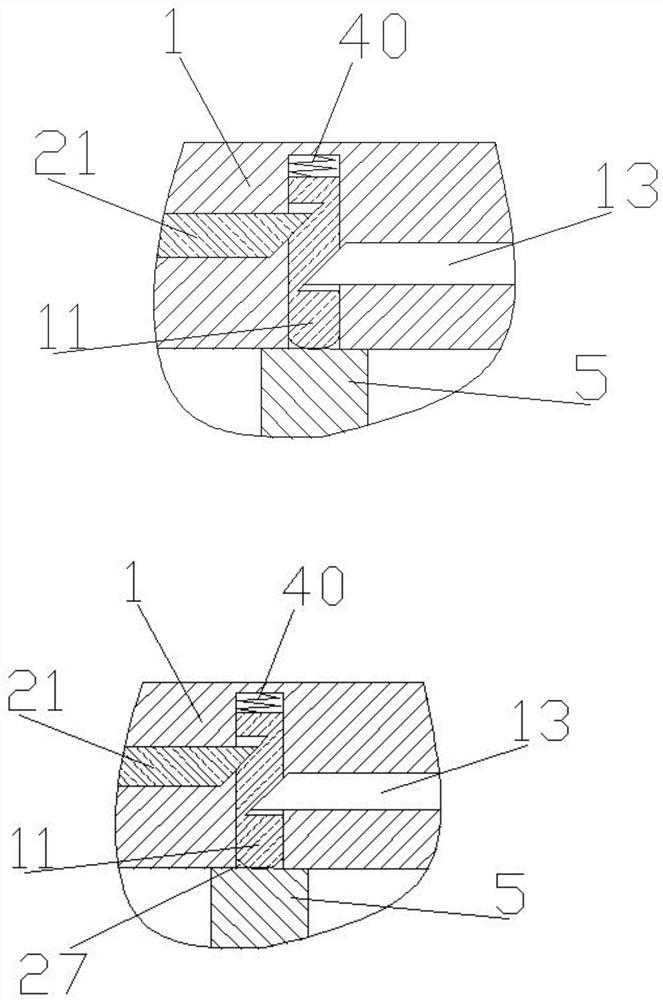

[0018] Such as Figure 1-7 As shown, a kind of compressible material cabin includes a hull 1, a telescopic plate 2 arranged on the hull 1, a stern plate arranged at the end of the hull 1, an electric push rod 4 arranged inside the hull 1, and an electric push rod 4 fixedly arranged on the The push plate 3 on the top is characterized in that: it also includes a transmission device arranged inside both sides of the hull 1, an anti-jamming device arranged inside the telescopic plate 2, and a self-locking device arranged in the tail plate 3, and the transmission device includes The first sliding space 27 arranged in the hull 1, the first spring 40 arranged between the inner wall of the first sliding space 27 and the first inspiring rod 11, the first spring 40 slidably arranged in the first sliding space 27 back and forth, The inspiring rod 11 , the first wedge-shaped guide rod 21 slidably disposed in the first sliding space 27 left and right, and the second wedge-shaped guide rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com