Torsion bar type piezoelectric actuating device

A technology of piezoelectric actuation and torsion bar, which is applied to the device and coating of the surface coating liquid, which can solve the problems of user difficulty, affecting the accuracy of the output of the glue, and the change of the pre-force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following will disclose multiple implementations of this case with diagrams, and for the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the present case. That is to say, in some implementations of this case, these practical details are unnecessary. In addition, in order to simplify the drawings, some existing conventional structures and components will be shown in a simple and schematic manner in the drawings.

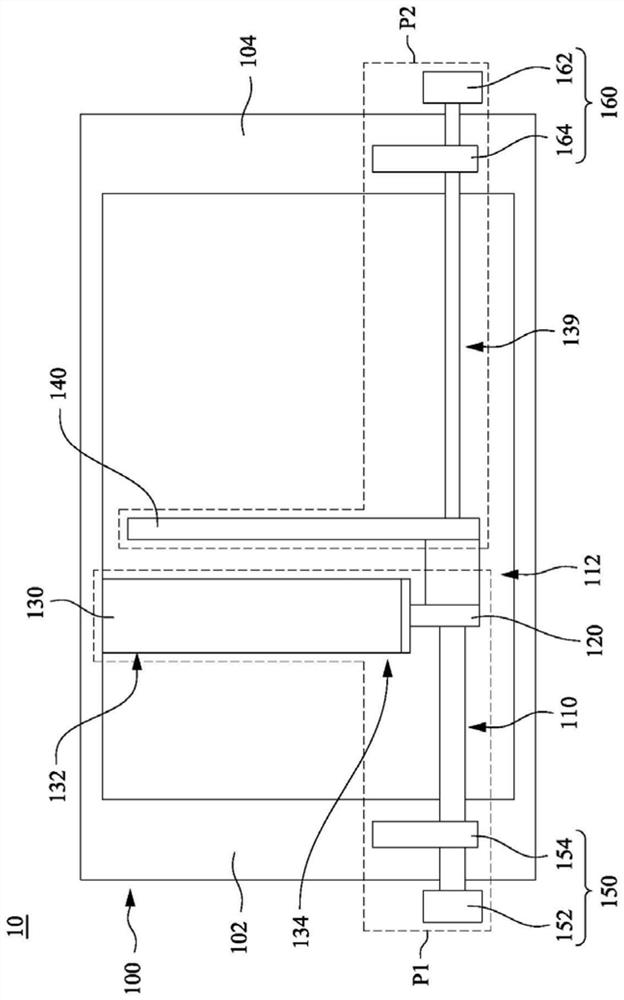

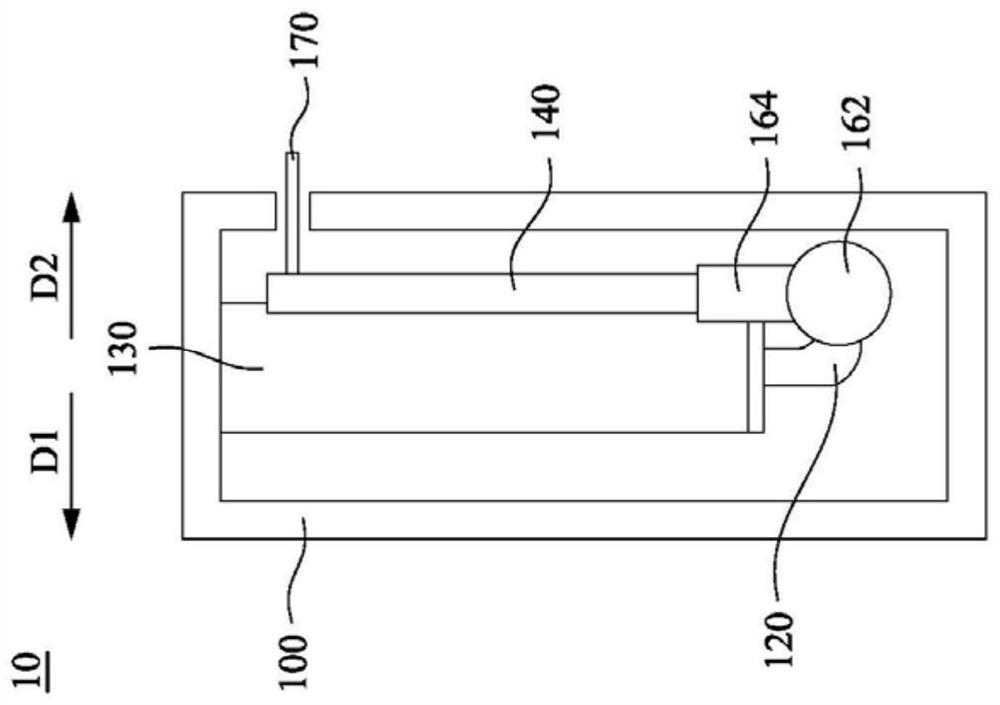

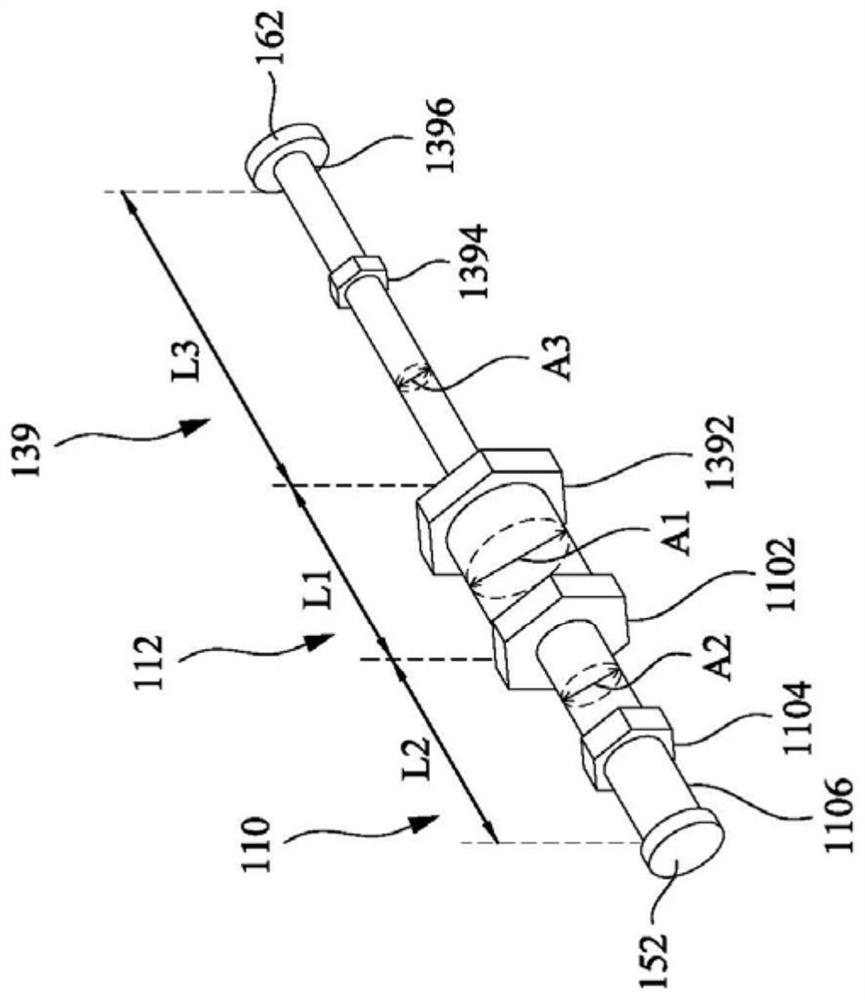

[0046] Please refer to figure 1, which is a schematic front view of the piezoelectric actuator 10 according to some embodiments of the present application. In some embodiments, the piezoelectric actuator 10 includes a housing 100, a first torsion bar 110, a first force application unit 120, a piezoelectric unit 130, a second torsion bar 139, a second force application unit 140, a first The pre-force adjustment module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com