Two-side branding equipment for square toy parts for children

A branding and square technology, applied in embossed ornaments, decorative arts, etc., can solve the problems of small production scale, large manpower and time, and high production cost, and achieve the effects of reducing manpower, improving work efficiency, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Billy, digital toy parts, two-sided, such as figure 1 As shown, the base 1, the strut 2, the mounting plate 3, the mounting mechanism 4, and the power mechanism 5 are included, and the intermediate of the base 1 is uniformly provided with the strut 2, and there is a mounting plate 3 between the struts 2, and the base 1 is provided. Branding mechanism 4, the power mechanism 5 is provided on the right side of the rear portion of the base 1.

[0071] When people need a square toy to make the bilony, the toy is placed on the mounting plate 3, and the power mechanism 5 is controlled to press the padding mechanism 4 so that the brand is branded.

Embodiment 2

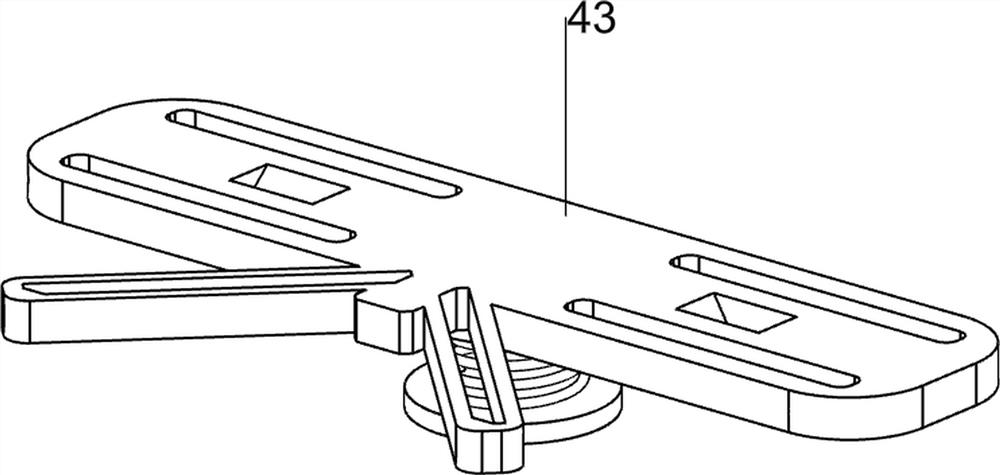

[0073] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 with Figure 8 As shown, the printing mechanism 4 includes a first slide rail 40, a first spring 41, a first slider 42, a lower pressure plate 43, a slide plate 44, a support rod 45, and a mount 46, and a base 1 side. The slide rail 40, the first sliding rail 40 slides to connect the first slider 42, and the first spring 41 is connected between the inner bottom portion of the first slide rail 40 and the first slider 42, between the first slider 42 The connection is provided with a lower pressure plate 43, and both sides of the lower side plate 43 are connected to the sliding plate 44, and both sides of the rear left side of the base 1 are provided with two support rods 45, and the two support rods 45 are slidably equipped with a pad. 46. The drug 46 is slidable with the slide plate 44.

[0074] The member of the power mechanism 5 presses the lower presser 43 down, and the lower pressure plate 43 is pressed...

Embodiment 3

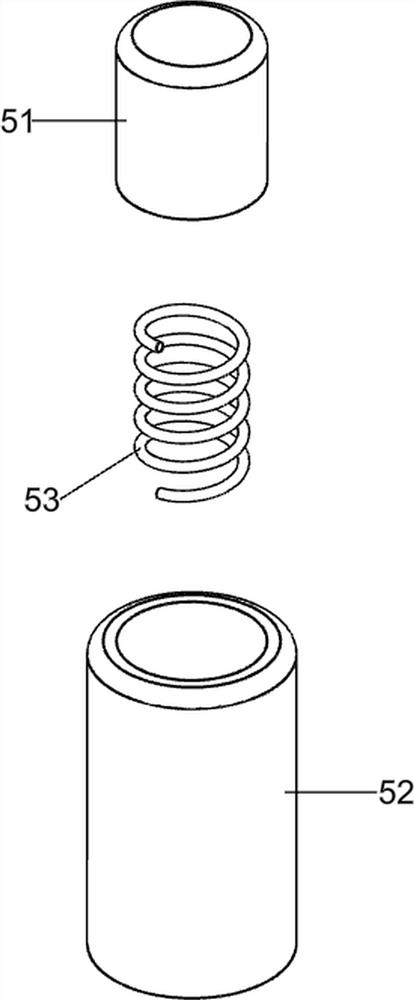

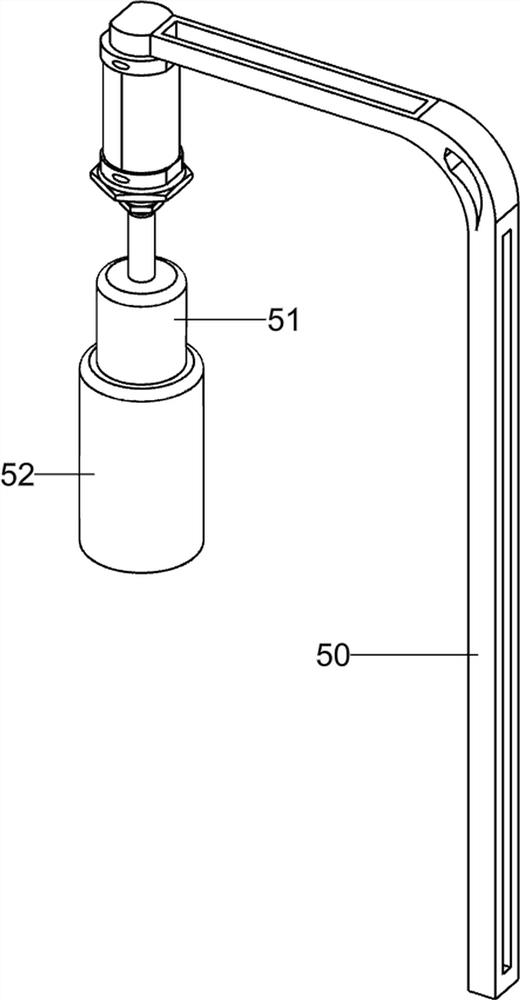

[0076] On the basis of Example 2, such as Figure 5 , Figure 6 , Figure 7 with Figure 9 As shown, the power mechanism 5 includes an L-shaped rod 50, a second slider 51, a hollow cylinder 52, and a second spring 53, and a L-shaped rod 50 is provided on the back right side of the base 1, and a cylinder is provided at the top of the L-shaped bar 50. A second slider 51 is provided at the bottom of the cylinder, and the outer sliding type of the second slider 51 is provided with a hollow cylinder 52, and the bottom wall of the hollow cylinder 52 and the top wall in the second slider 51 is connected to the second spring 53.

[0077] When the brand is restarted, the cylinder elongation is controlled, and the second slider 51, the hollow cylinder 52 and the second spring 53 are simultaneously moved, and when the hollow barrel 52 is bonded to the lower pressure plate 43, the lower pressure plate 43 is moved downward. Further, the mount 46 is slid inward, and the imprint of the toy is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com