Automobile gear shifting high-low temperature durability detection device

A technology of automobile gear shifting and detection device, which is applied in the direction of measuring device, testing of mechanical parts, and testing of machine/structural parts, etc. problems, to achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

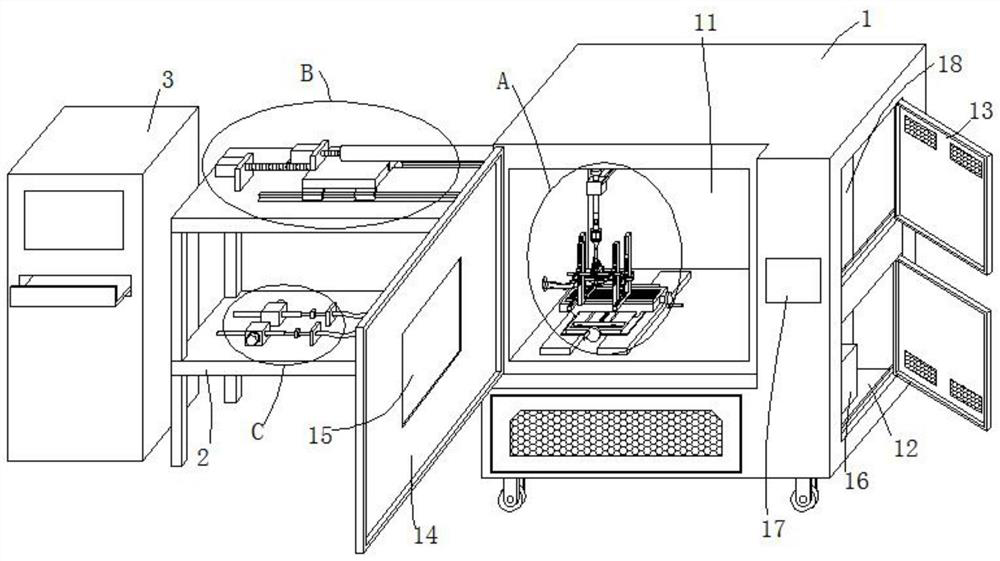

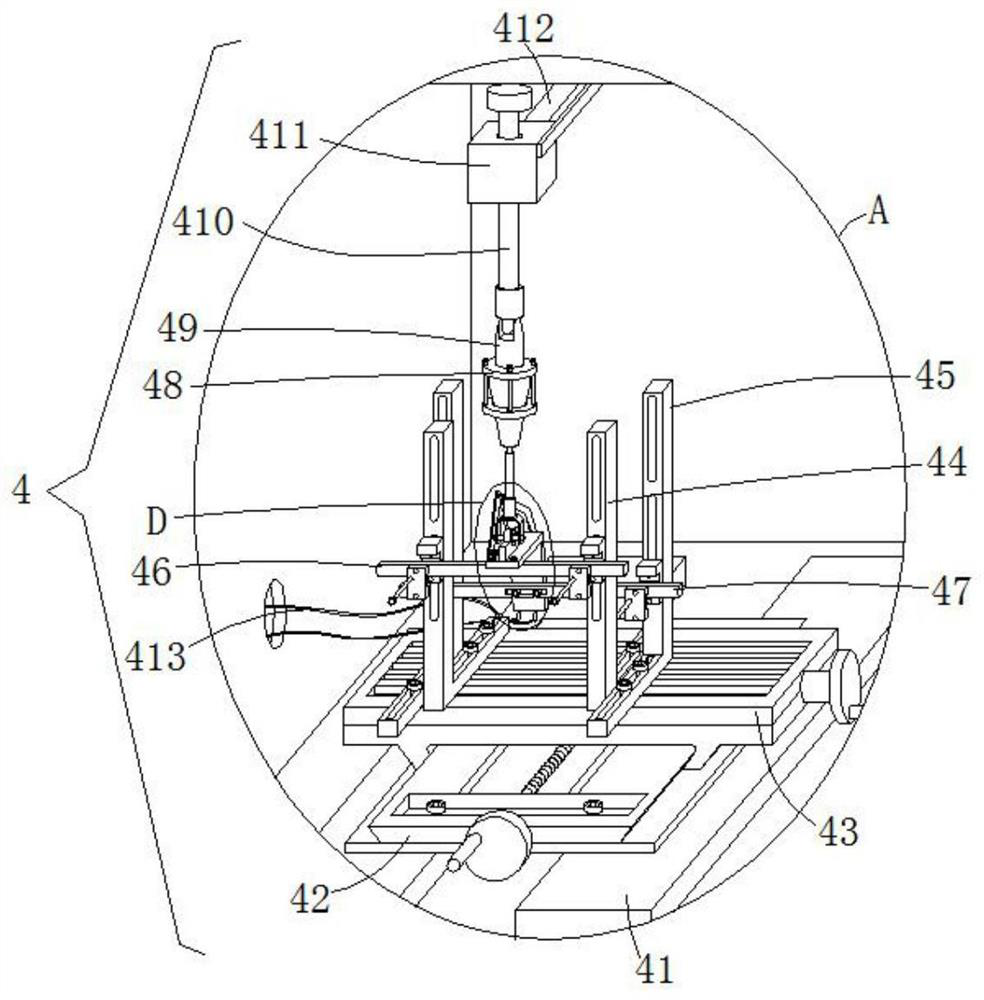

[0026] see Figure 1-7 , the present embodiment provides an automobile shifting high and low temperature durability detection device, including a detection body 1, an automobile shifting high and low temperature durability test cabinet 3, a detection mechanism 4, a support frame 2, a reversing mechanism 5 and a transmission mechanism 6, and the detection body 1. There is a testing room 11 on the left side of the front end. The testing room 11 provides a place for the high and low temperature durability testing of automobile gear shifting. There is a storage room 12 on the right side of the testing body 1. 11 temperature air conditioner 16 and control unit 18, the right side of the front surface of the detection body 1 is embedded with a smart touch screen 17 for manipulating the control unit 18, the smart touch screen 17 can be controlled by the staff through the control unit 18 The temperature height of the air conditioner 16 is so that the durability test of the automobile g...

Embodiment 2

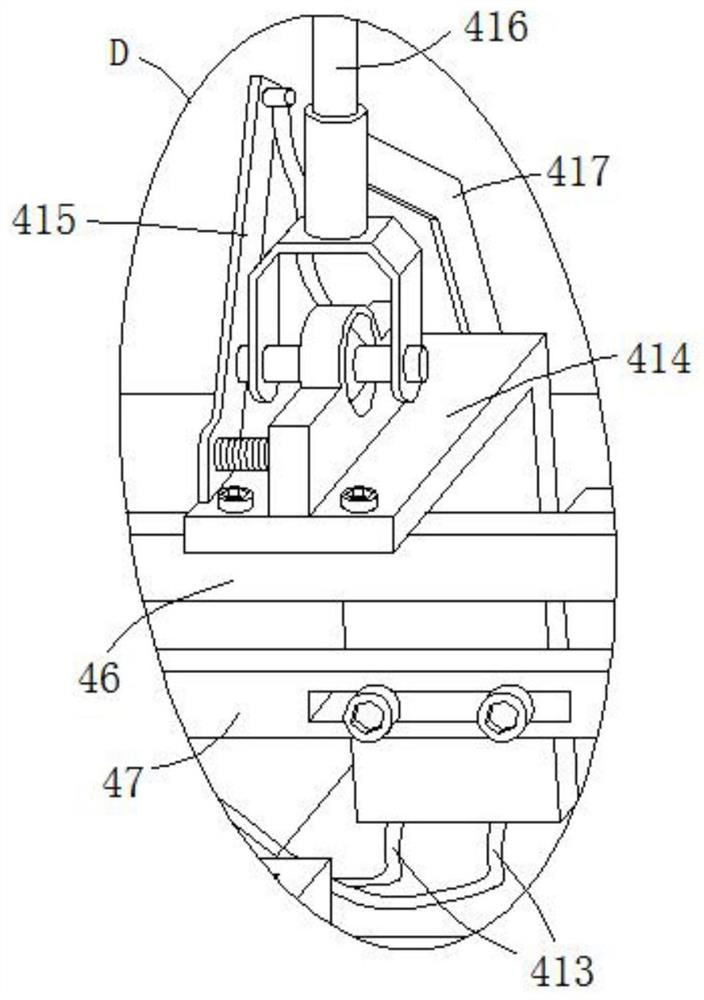

[0037] see figure 2 , image 3 and Figure 6 , further improvements have been made on the basis of Example 1:

[0038] The outer wall of the flexible shaft 65 is slidingly sleeved with a protective sleeve 413, which is convenient to play a good role in protecting the flexible shaft 65.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com