Production line inspection system for smart factory

A technology of inspection system and factory, applied in the field of inspection system, can solve the problems that are not suitable for manual inspection, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

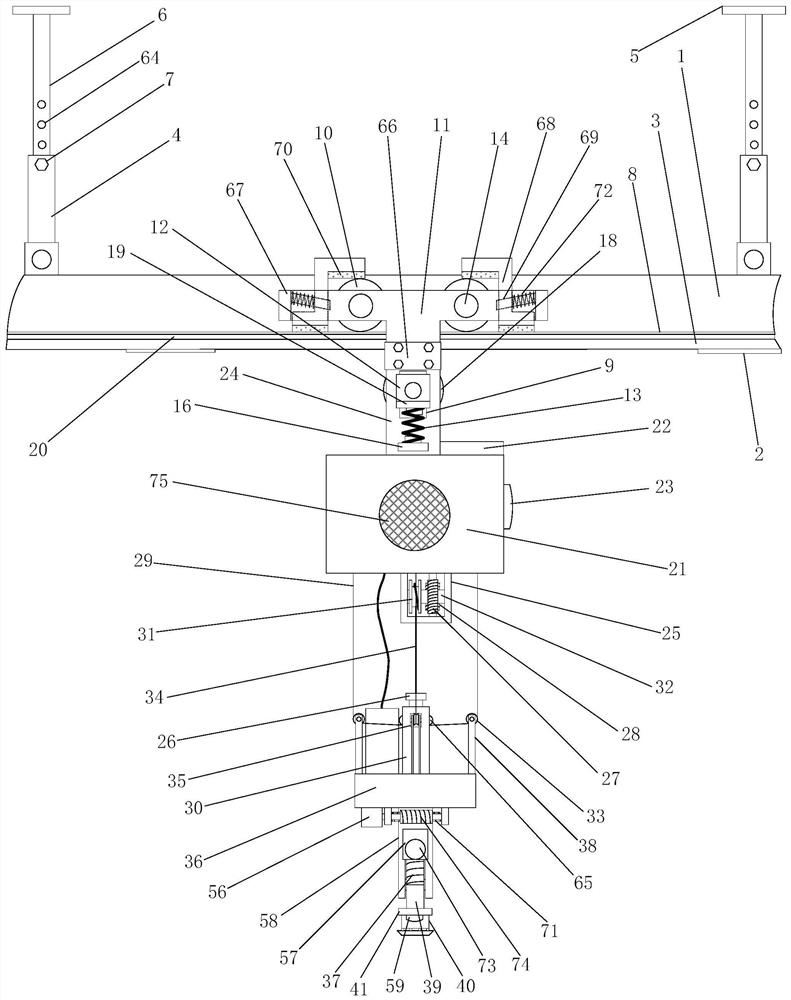

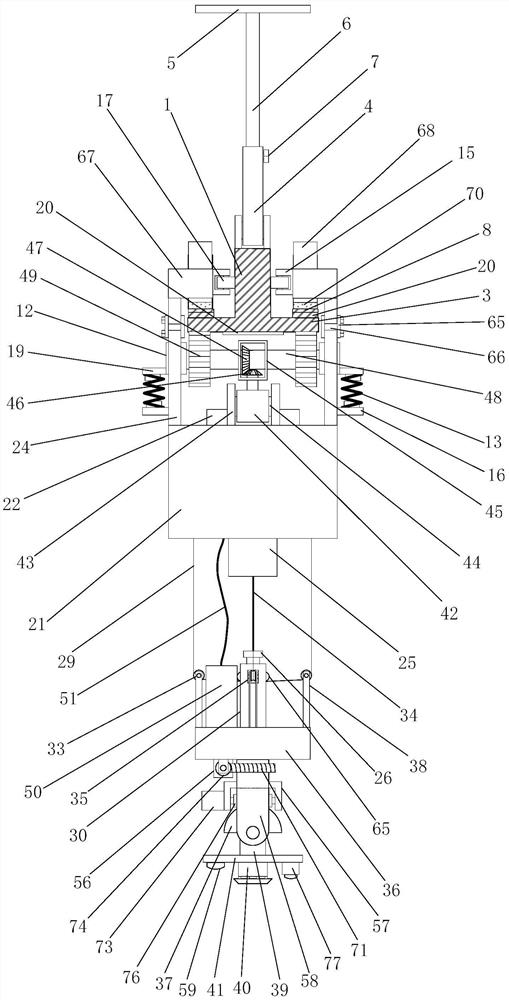

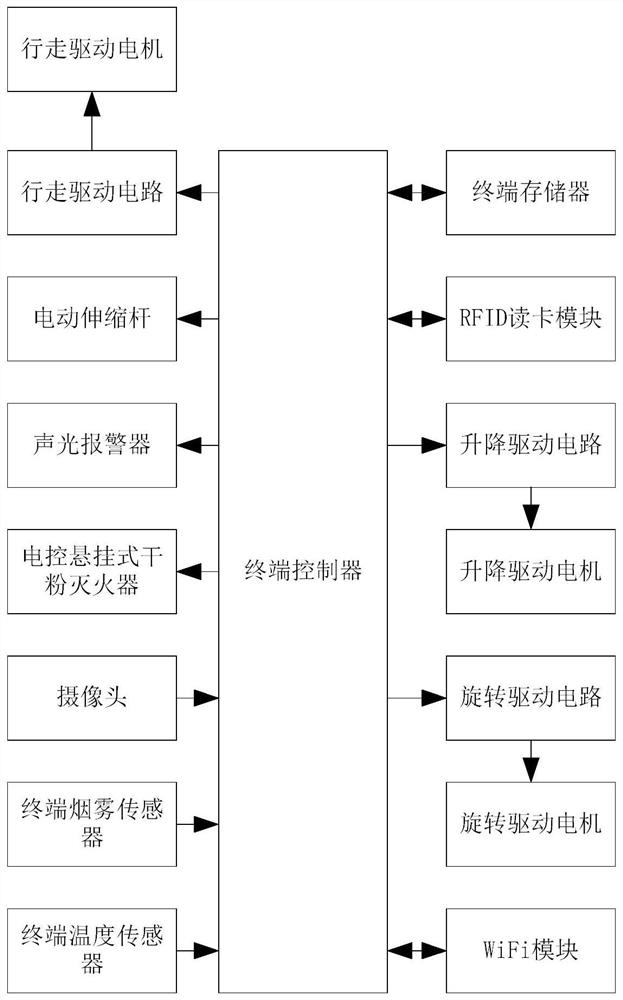

[0023] Such as Figure 1-3 As shown, the production line inspection system for smart factories disclosed by the present invention includes: a walking track 1, a mobile mounting mechanism, a control box 21, a steel rope lifting mechanism, an angle adjustment mechanism, a terminal smoke sensor 40, a camera 77 and a terminal temperature sensor 59;

[0024] On the upper side of the walking track 1, each suspension installation mechanism is arranged at intervals; the suspension installation mechanism includes a height adjustment sleeve 4, a height adjustment rod 6 and a top mounting plate 5; the lower end of the height adjustment sleeve 4 is hingedly installed on On the upper side of the walking track 1; the upper end of the height adjustment rod 6 is fixedly installed on the top mounting plate 5; the lower end of the height adjustment rod 6 is inserted in the height adjustment sleeve 4, and the height adjustment rod 6 is provided with Each height adjustment hole 64; a height posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com