Low-temperature cold shrinkage prevention eccentric positioning device for superconducting magnet

A technology of superconducting magnets and positioning devices, applied in the directions of superconducting magnets/coils, magnetic objects, transformer/inductor parts, etc. Deformation and other problems, to avoid the overall height drop, avoid the problem of magnet eccentricity, and reduce the preload requirement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific examples.

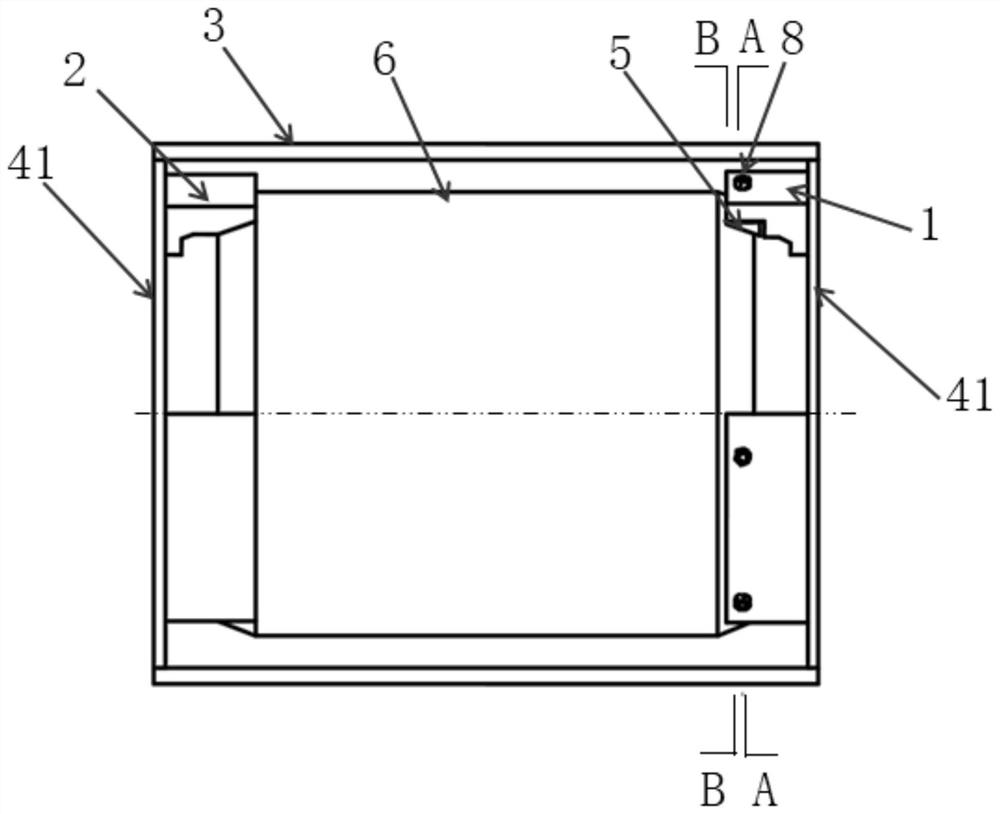

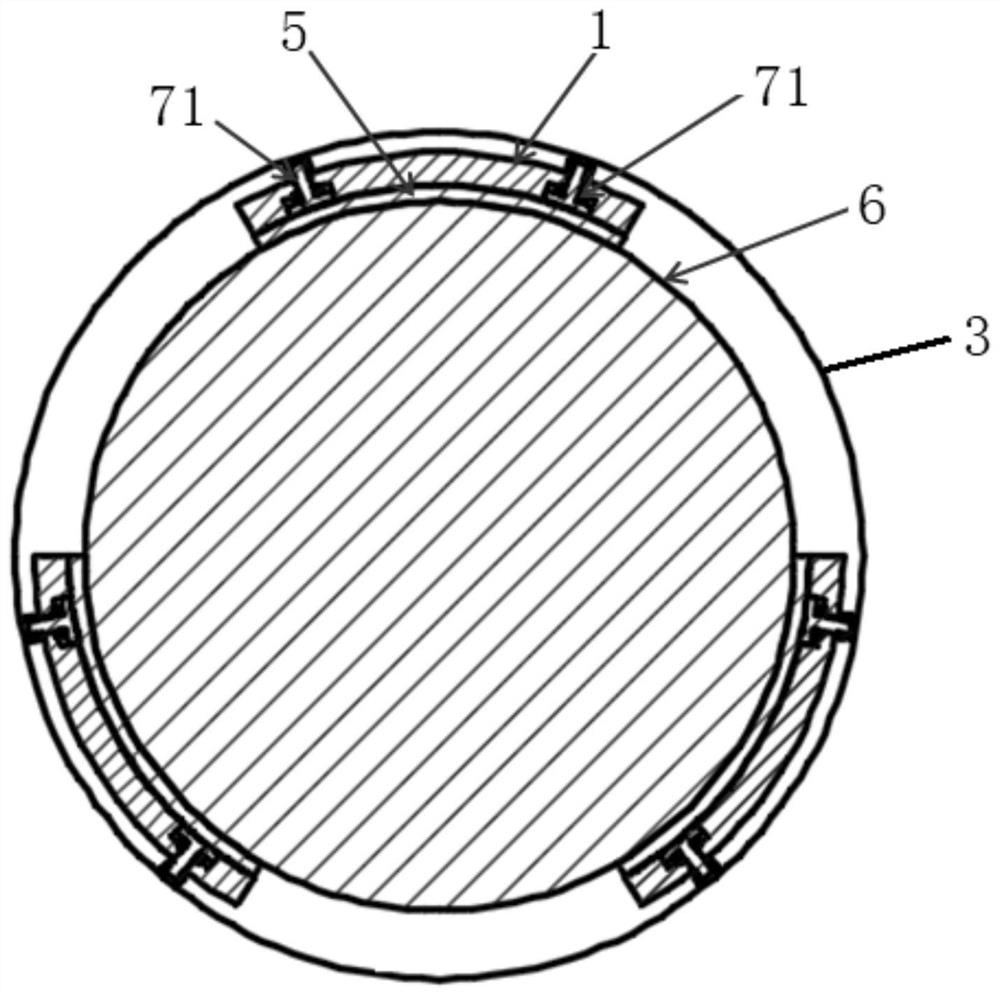

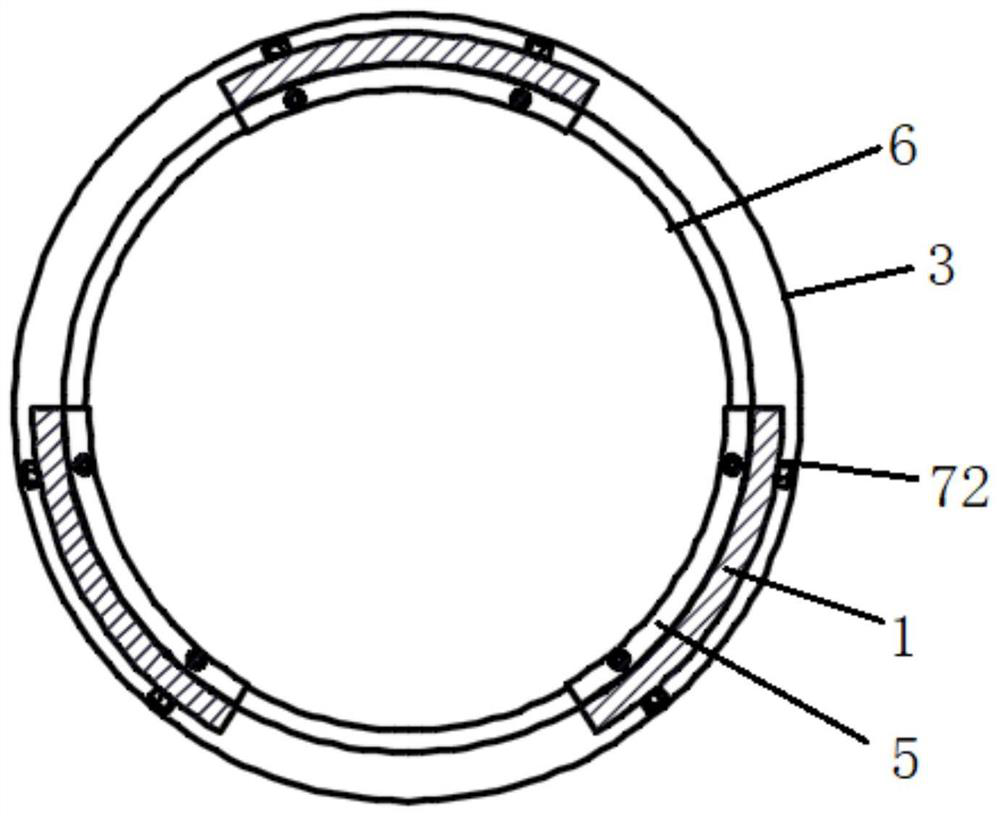

[0022] See attachment figure 1 Adherent image 3 A anti-low temperature coldness eccentric positioning device for superconducting magnets, including pushing end positioning block 1, floating end positioning block 2, a cylinder 3, pushing the end plate 41, a floating end plate 42, and an inner cone 5 The driving end plate 41 and the floating end plate 42 are respectively mounted on both ends of the cylinder 3, and the aluminum superconducting magnet housing 6 is formed to narrow the cone structure 61; a plurality of floating end positioning The block 2 is mounted on the floating end plate 42, and each floating end positioning block 2 is formed with a cone surface that matches the cone structure 61, so that the superconducting magnet housing 6 passes through several block floating ends at the floating end. Positioning block 2 matches the positioning; seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com