Self-cleaning power distribution cabinet

A self-cleaning technology for power distribution cabinets, which is applied in substation/power distribution device casings, electrical components, and general water supply conservation, etc., can solve the problem of high cleaning costs for power distribution cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

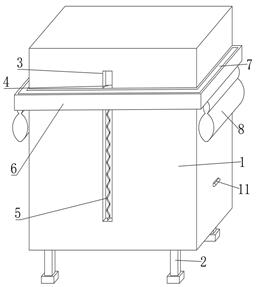

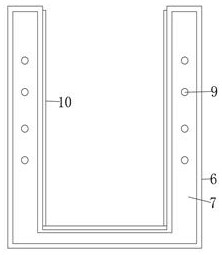

[0028] refer to Figure 1-4 , a self-cleaning power distribution cabinet, including a power distribution cabinet body 1, a plurality of legs 2 are symmetrically fixed on both sides of the bottom of the power distribution cabinet body 1 by bolts, and a first chute 3 is provided at the rear end of the power distribution cabinet body 1, and the second A slider 4 is slidably connected in the chute 3, and the bottom of the slider 4 is fixed with a first spring 5 by bolts. The water receiving plate 6 is fixed by bolts, the cross section of the water receiving plate 6 is set into a U shape, the top of the water receiving plate 6 is provided with a water receiving tank 7, and the bottom of the water receiving tank 7 is provided with a plurality of water inlet holes 9, and the bottom of the water receiving plate 6 has two holes. There are two water receiving tanks 8 fixed laterally symmetrically by bolts. The water receiving tanks 8 communicate with the water inlet holes 9. The cross s...

Embodiment 2

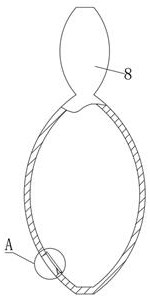

[0032] refer to Figure 1-7 , a self-cleaning power distribution cabinet, the top inner wall of the water outlet 12 is provided with a first groove 15, the first groove 15 is bonded with a first permanent magnet 16, the top of the top block 11 is provided with a second groove 17, the first The second permanent magnet 18 is bonded in the second groove 17, and the first permanent magnet 16 and the second permanent magnet 18 have different magnetic poles opposite to each other. Two second slide grooves 19 are arranged symmetrically on both sides of the power distribution cabinet body 1. The second chute 19 is fixed with a third spring 20 by bolts, and the outside of the third spring 20 is fixed with a block 21 by bolts. There are a plurality of third grooves 22 on the top of the arc surface of the block 21, and a plurality of varistor rollers 25 distributed in an annular array are connected to the third grooves 22 through bearing rotation. The outer surface of the varistor roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com