Wave-soldering tin coating tool for DIP-series packaging components

A component and wave soldering technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of unguaranteed tinning quality and low tinning efficiency, so as to improve tinning efficiency, ensure welding quality, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

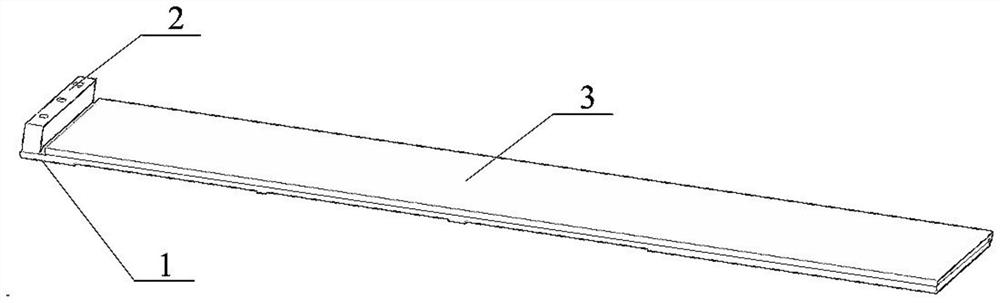

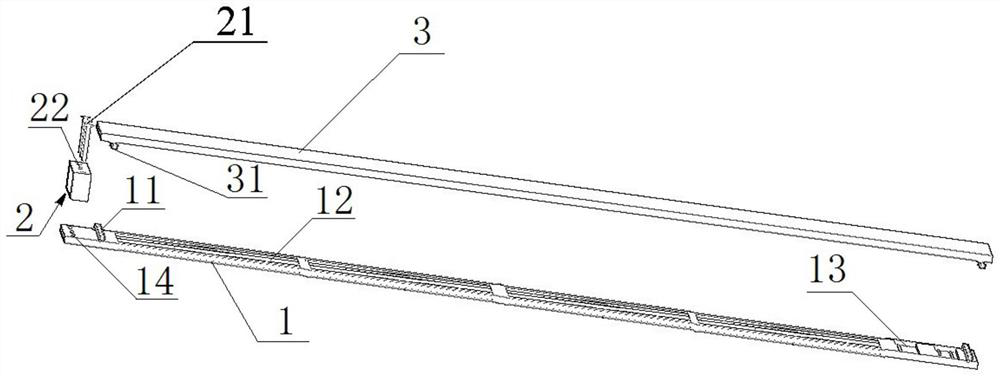

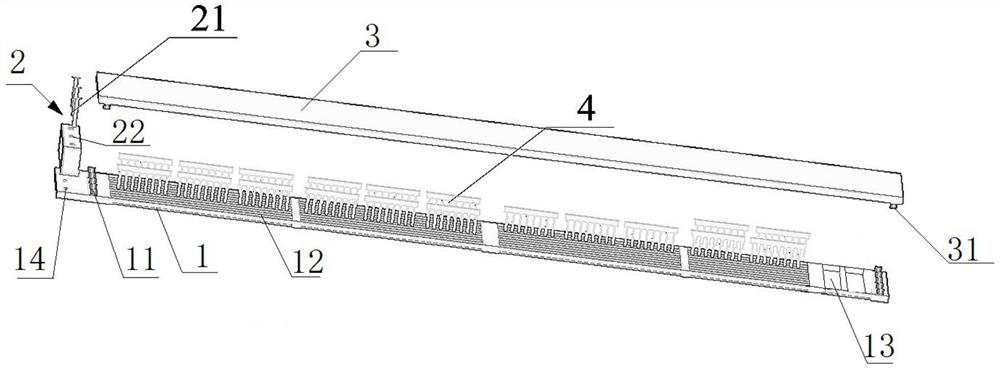

[0036] The present invention provides a DIP series packaging component wave soldering tin frock, such as figure 1 , figure 2 and image 3 As shown, it includes the body of the wave soldering tin enamel tooling body, and the wave soldering tin enamel tooling body includes the tooling base plate 1 and the tooling cover plate 3 that hold the DIP series package components 4; the tooling base plate 1 and the tooling cover plate 3 are both rectangular plates, and the tooling The base plate 1 is provided with several grooves 12 for DIP series packaged components, which are used to place the DIP series packaged components 4; the tooling cover plate 3 is connected to the tooling base plate 1 through an adsorption unit.

[0037] The clamping surfaces of the tooling base plate 1 and the tooling cover...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap