Automatic packaging box handle assembling production system

An automatic assembly and production system technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as time-consuming, low efficiency, and many steps, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application will be described in further detail below in conjunction with all the accompanying drawings.

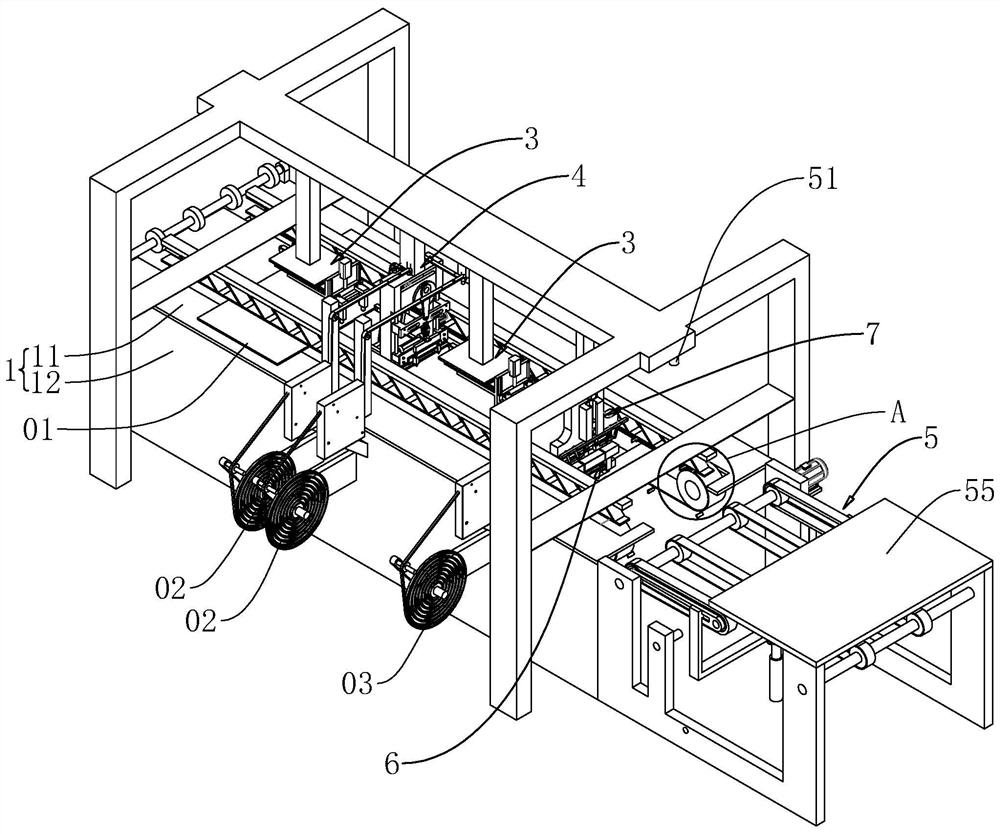

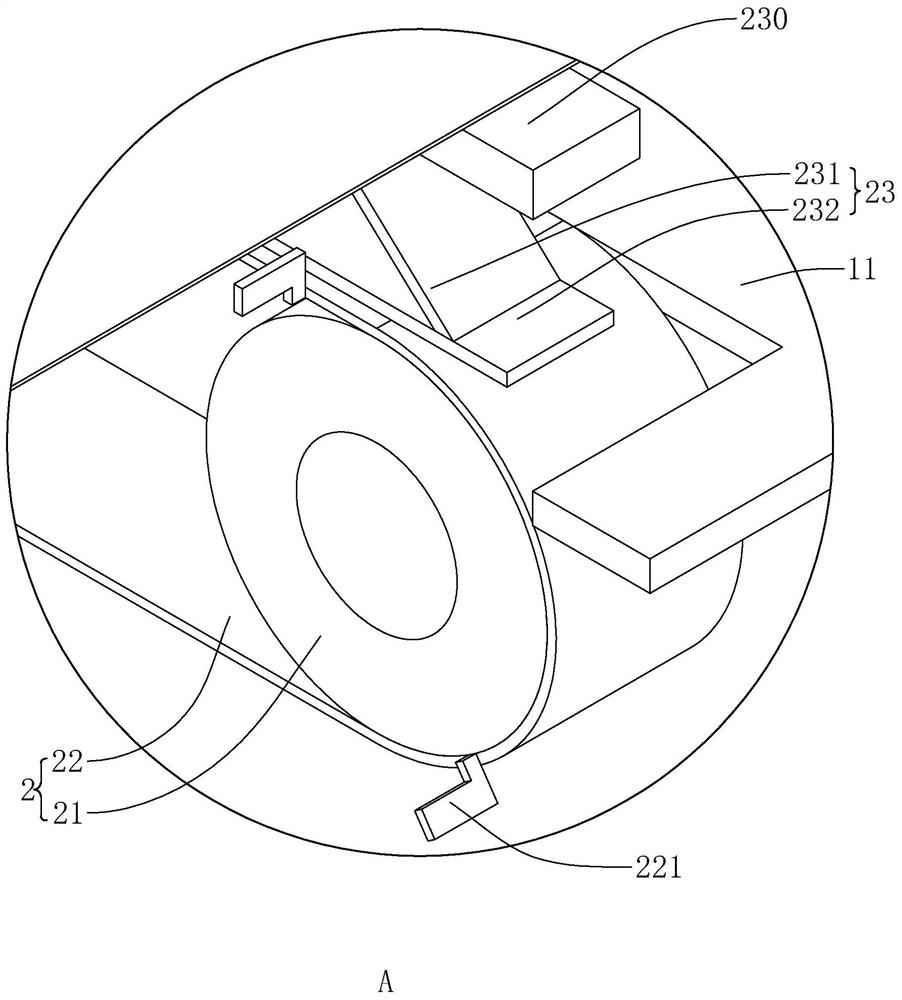

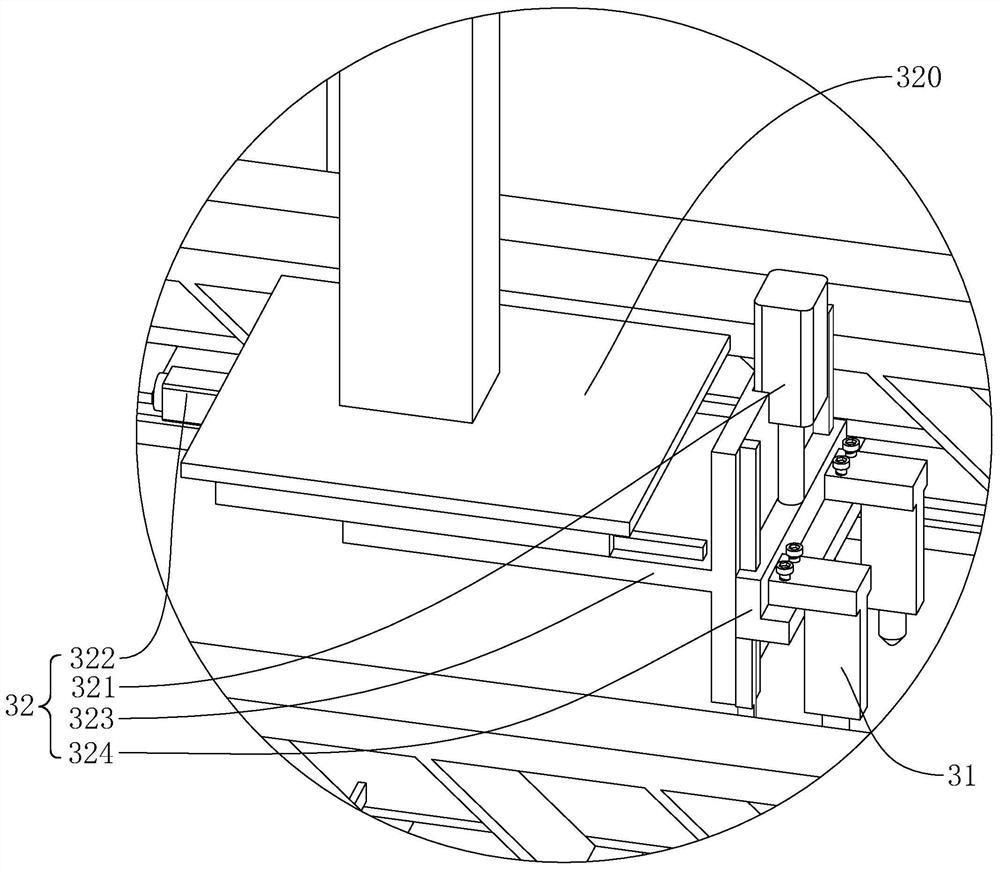

[0042] refer to figure 1 , is a packing box handle automatic assembly production system disclosed in the present application, including a frame 1, the frame 1 includes two bottom plates 11 and two side plates 12, the side plates 12 are perpendicular to each other and vertically arranged on the ground, Bottom boards 11 are arranged on opposite planes of the two side boards 12 , the two bottom boards 11 are horizontally arranged and flush with each other, and a cavity is formed between the two bottom boards 11 . A support plate for supporting the middle part of the cardboard 01 is arranged between the cavities, and the support plate is flush with the bottom plate 11 . A conveying mechanism 2 for conveying the cardboard 01 is arranged in the cavity, and the conveying mechanism 2 is arranged on the frame 1 . The side plate 12 is provided with a gluing mechanism 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap