Film continuous punching device

A punching device and film technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of slow punching speed, complex structure, and feeding stoppage of the bag making machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

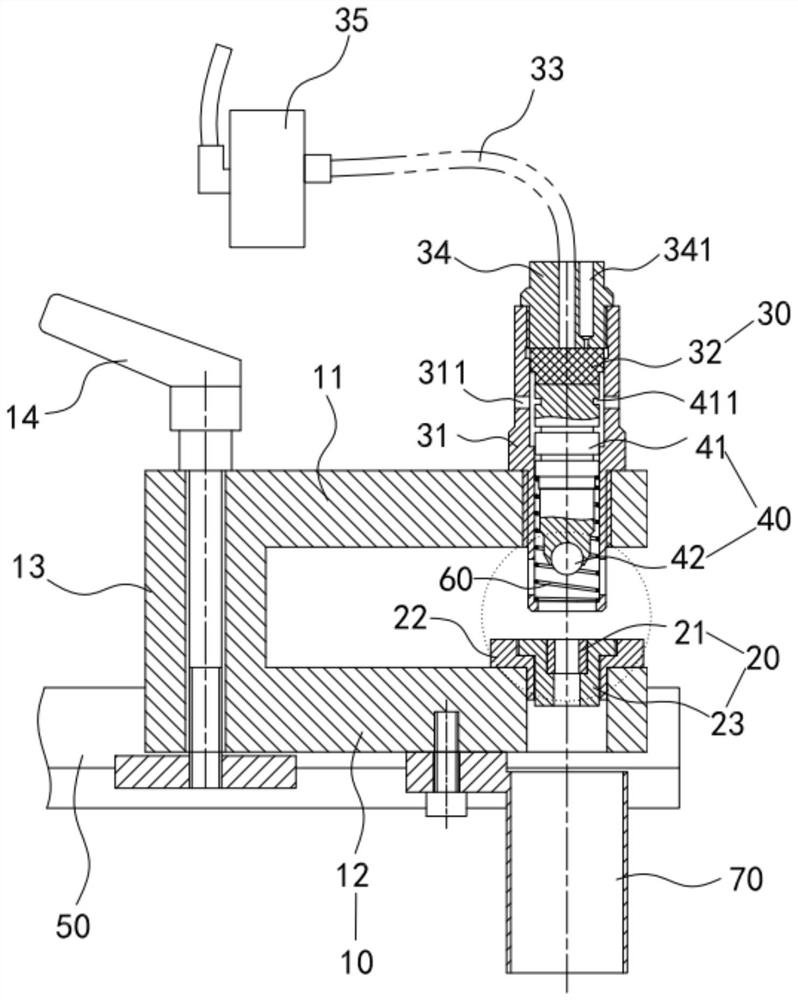

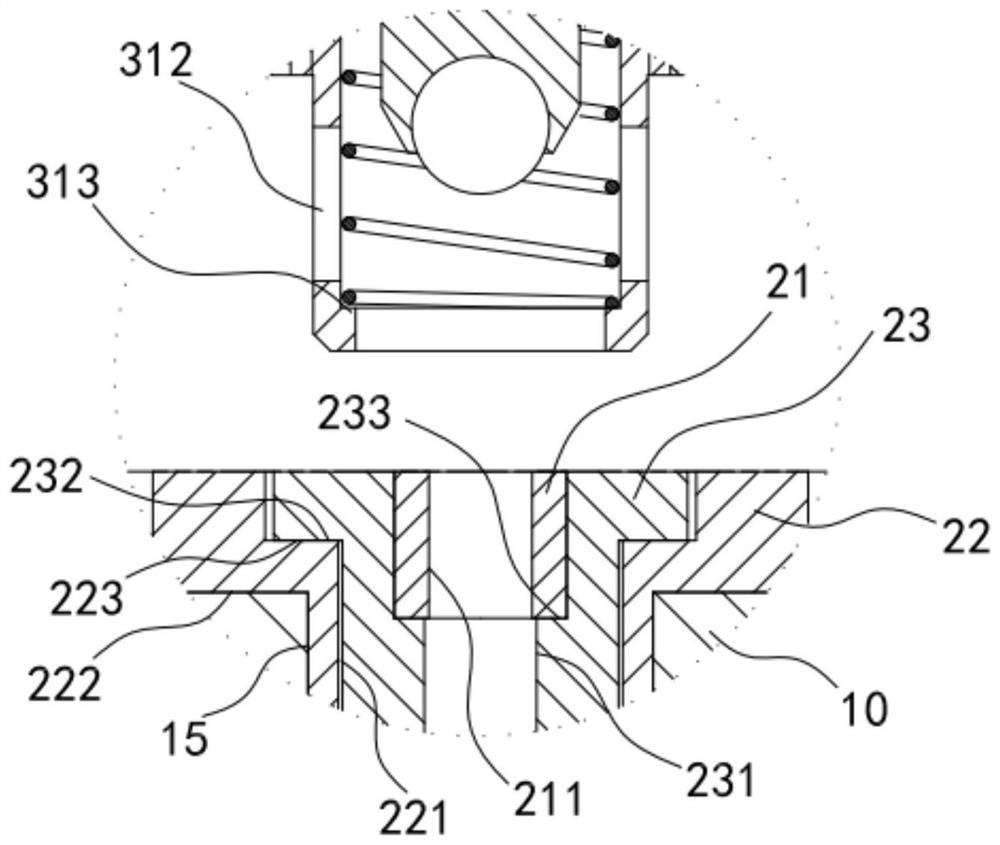

[0020] Please refer to figure 1 , a film continuous punching device, including a bracket 10, a bottom knife device 20, a pneumatic piston device 30, and a punching ball device 40.

[0021] The bracket 10 includes an upper support portion 11 , a lower support portion 12 and a connecting portion 13 connecting the upper support portion 11 and the lower support portion 12 . Wherein, the bottom knife device 20 is arranged on the lower supporting part 12 , the pneumatic piston device 30 is arranged on the upper supporting part 11 , and the punching ball device 40 is opposite to the bottom knife device 20 up and down. In this embodiment, the bracket 10 is in the shape of "匸".

[0022] The support 10 is fixed on the guide rail 50 by the handle screw 14, and the guide rail 50 is fixed on the frame of the bag making machine. The locking nut is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com