A CubeSat deployer based on 3D printing

A 3D printing and cubic technology, which is used in artificial satellites, space navigation ground equipment, space navigation equipment, etc., can solve the problem of unadjustable launch speed, and achieve adjustable launch speed, easy hoisting and placement, and good applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

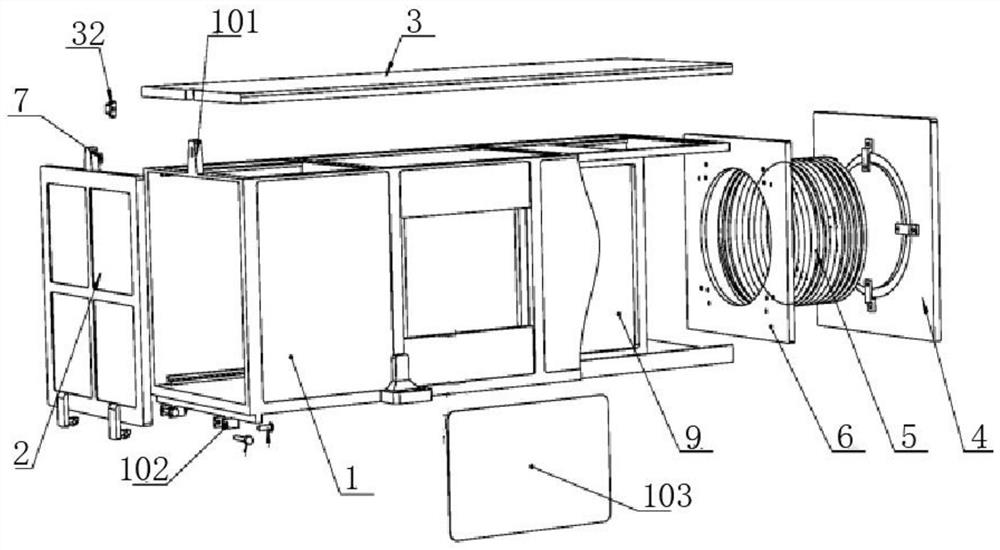

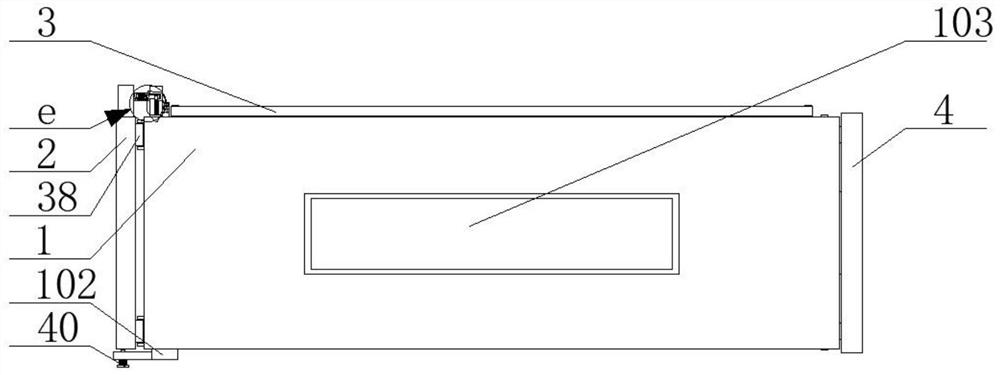

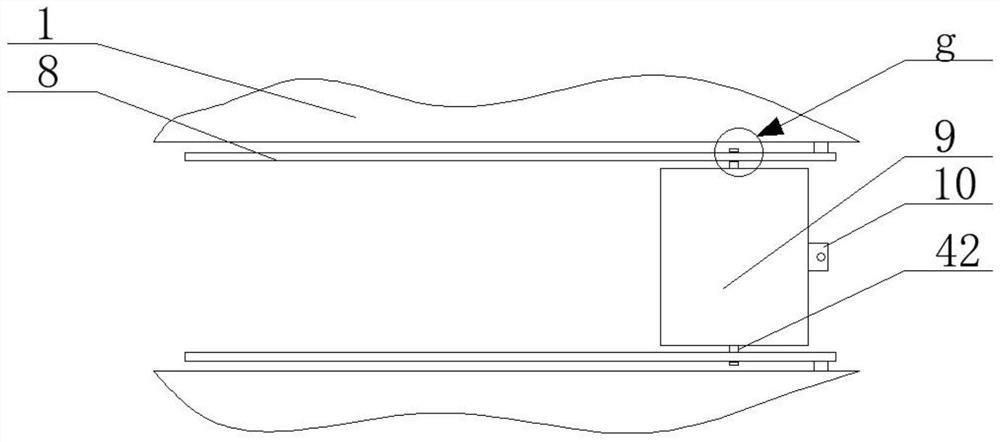

[0029] see figure 1 , figure 2 , image 3 , Figure 4 , Image 6 and Figure 7 , a 3D printing-based CubeSat deployer, comprising a box body 1 and a hatch 2 with hinges connected to it, wherein the box body 1, the hatch 2, the top plate 3 and the back plate 4 use 3D printing selective laser The melting technology realizes the additive manufacturing step through the fusion of the subordinate parts. The manufacturing is carried out on the support plate, and the metal powder is completely melted under the heat of the laser beam and formed by cooling and solidification. The upper end of the box 1 is bolted with a top plate. 3. The box body 1 is provided with an opening 12, the top plate 3 is inserted into the opening 12, the outer end surface of the opening 12 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com