Automatic warehousing device for electric power materials

A power material, automatic technology, applied in storage devices, conveyor control devices, conveyor objects, etc., can solve the problems of low work efficiency, time-consuming, labor-intensive, and chaotic storage, and achieve the effect of facilitating background monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

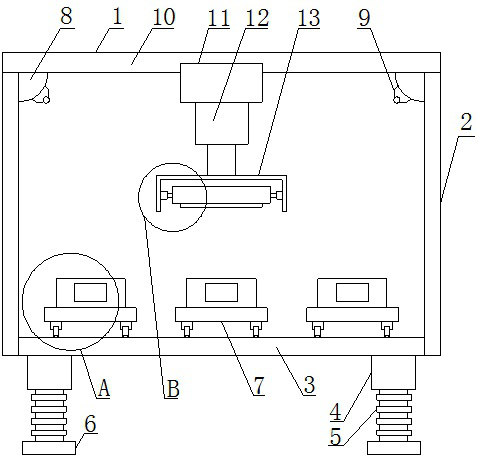

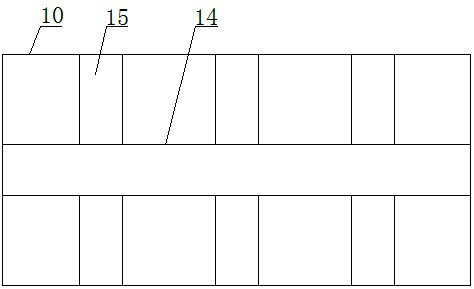

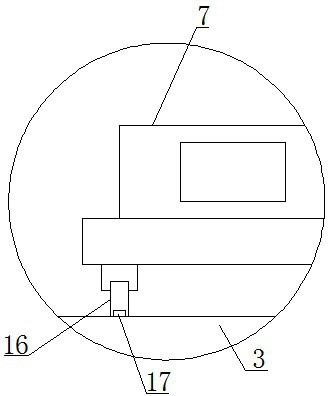

[0026] Such as Figure 1-11As shown, an automatic storage device for electric power materials includes a frame main body 1, a turning mechanism 20 and a grabbing mechanism 21. The left and right sides of the frame main body 1 are provided with infrared scanning side panels 2. The infrared scanning The inner side below the side plate 2 is provided with a workbench 3, the left and right sides of the bottom of the workbench 3 are provided with lead screw seats 4, and the bottom of the described lead screw seat 4 is provided with an adjusting screw 5. A base 6 is arranged below the bars 5, and three guide rails 17 are evenly arranged on the top of the workbench 3 from left to right, and a track guide vehicle 7 is arranged on the top of the guide rails 17. The infrared scanning side plate 2 The insides of the left and right sides of the top are all provided with a mounting frame 8, and the bottom of the mounting frame 8 is provided with a camera 9, and the top of the infrared scann...

Embodiment 2

[0032] Such as Figure 1-11 As shown, an automatic storage device for electric power materials includes a frame main body 1, a turning mechanism 20 and a grabbing mechanism 21. The left and right sides of the frame main body 1 are provided with infrared scanning side panels 2. The infrared scanning The inner side below the side plate 2 is provided with a workbench 3, the left and right sides of the bottom of the workbench 3 are provided with lead screw seats 4, and the bottom of the described lead screw seat 4 is provided with an adjusting screw 5. A base 6 is arranged below the bars 5, and three guide rails 17 are evenly arranged on the top of the workbench 3 from left to right, and a track guide vehicle 7 is arranged on the top of the guide rails 17. The infrared scanning side plate 2 The insides of the left and right sides of the top are all provided with a mounting frame 8, and the bottom of the mounting frame 8 is provided with a camera 9, and the top of the infrared scan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com