Wheel dimension detection method and system based on two-dimensional laser position detection technology

A two-dimensional laser and detection method technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of aggravating the vertical wear of the wheel rim, difficult to accurately locate the apex of the wheel rim, affecting the running stability of the train, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The accompanying drawings of the present invention are only for illustrative purposes, and should not be construed as limiting the present invention. In order to better illustrate the following embodiments, some components in the drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art, some known structures and their descriptions in the drawings may be omitted. understandable.

[0060] method embodiment

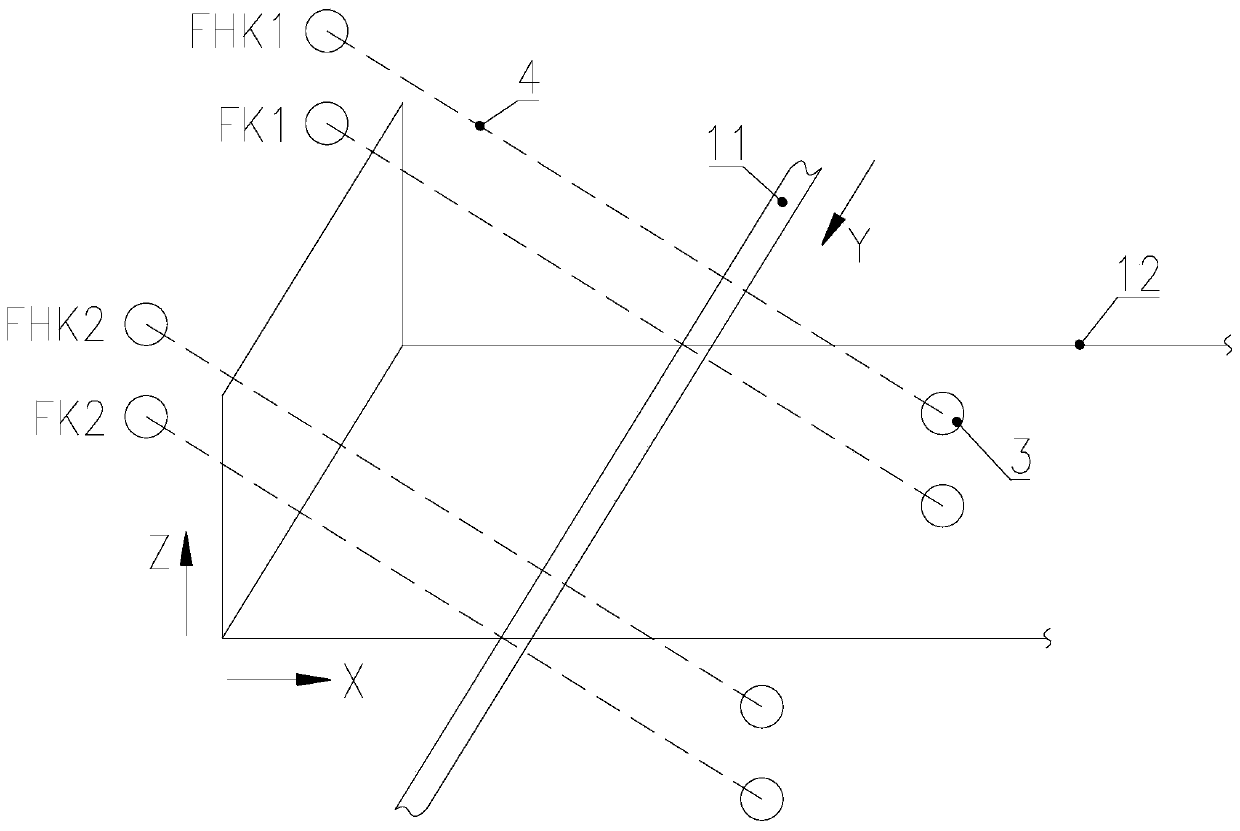

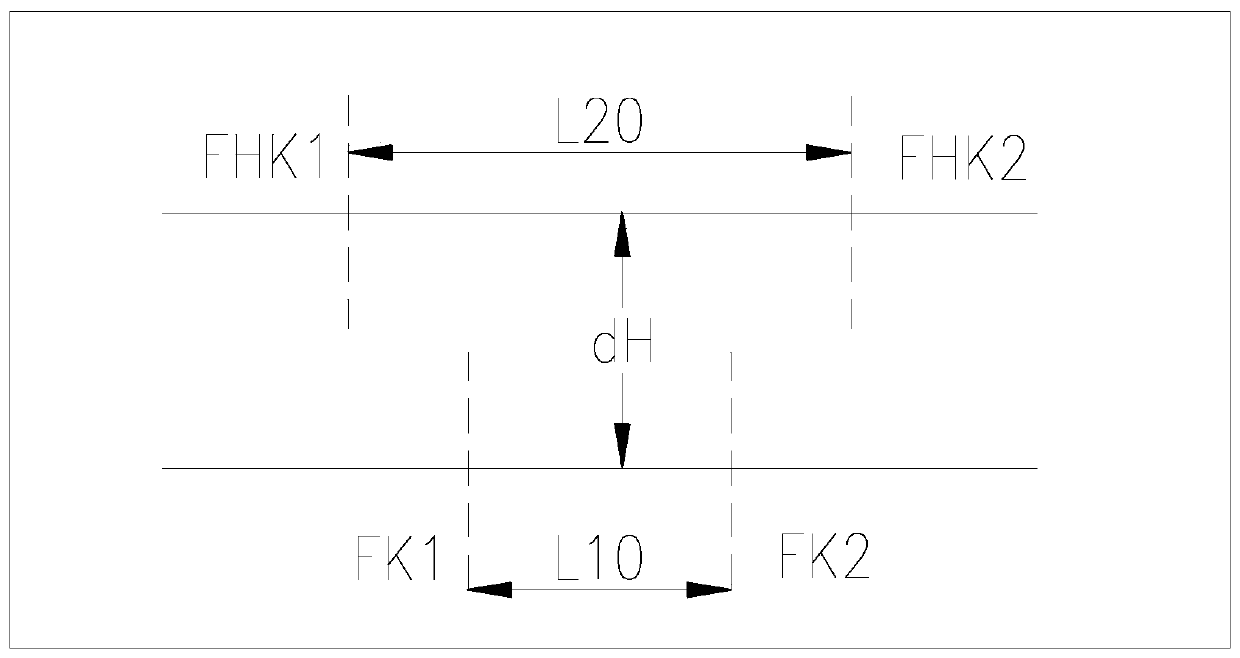

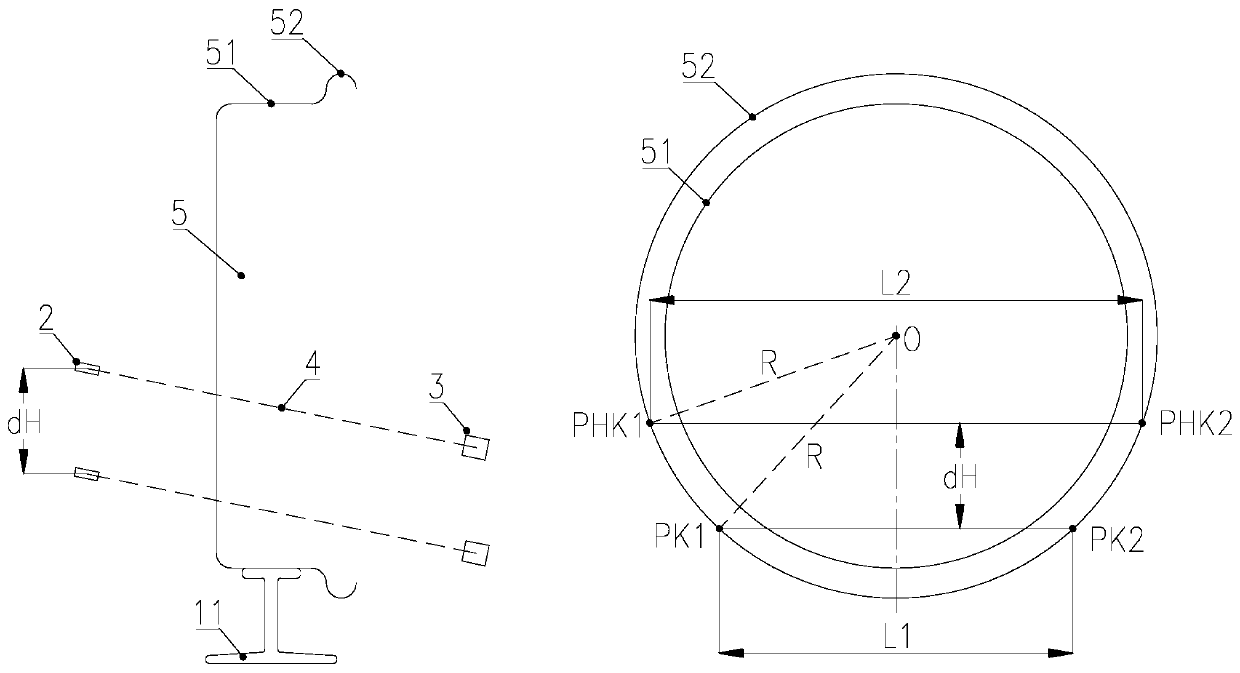

[0061] Such as figure 1 As shown, a detection method based on line laser dynamic detection of wheel rim dimensions, the direction of the sleeper between two rails is the X-axis, the direction of the wheel along the track is the Y-axis, formed perpendicular to the upper surface of the track The pillow surface establishes a coordinate system for the Z axis, and the detection method is used to detect the radius of the rim apex circle, the center of the circle, and the radius of the wheel tread of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com