A production system and production process of ultra-high molecular polyethylene fiber socks

A polyethylene fiber, ultra-high polymer technology, applied in textile and papermaking, knitting, weft knitting and other directions, can solve the problems of affecting the efficiency of production, affecting the quality and efficiency of hosiery, and reducing the tightness of the yarn. The effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

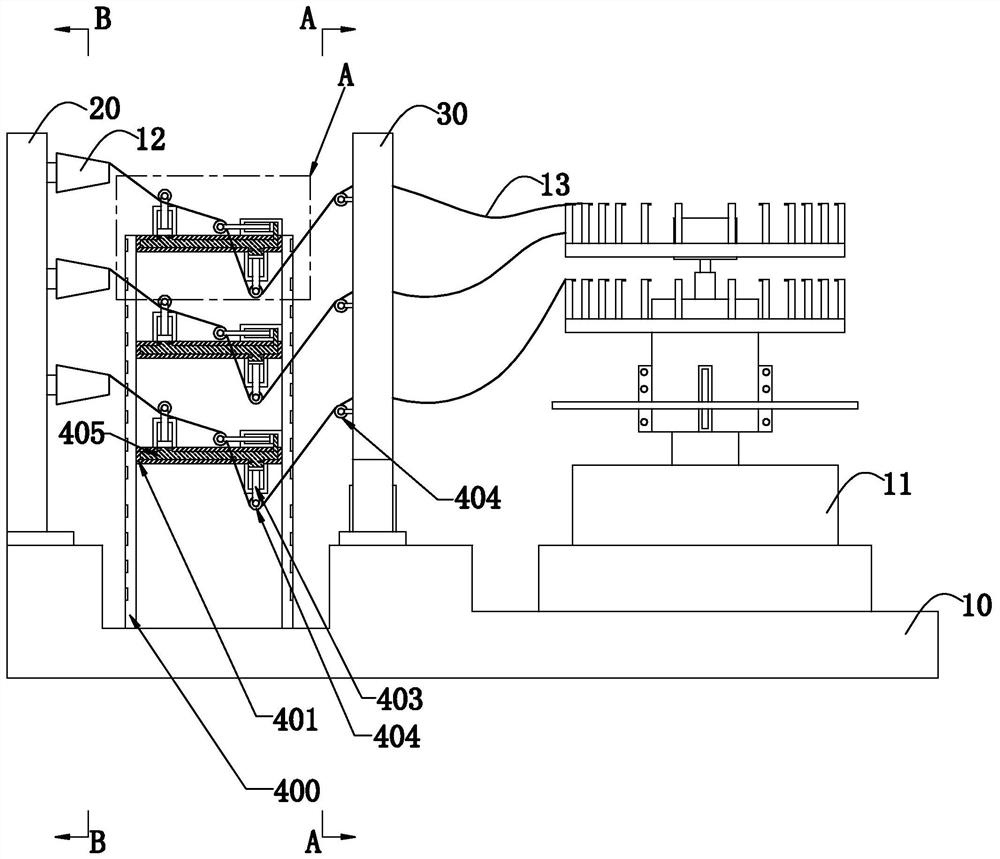

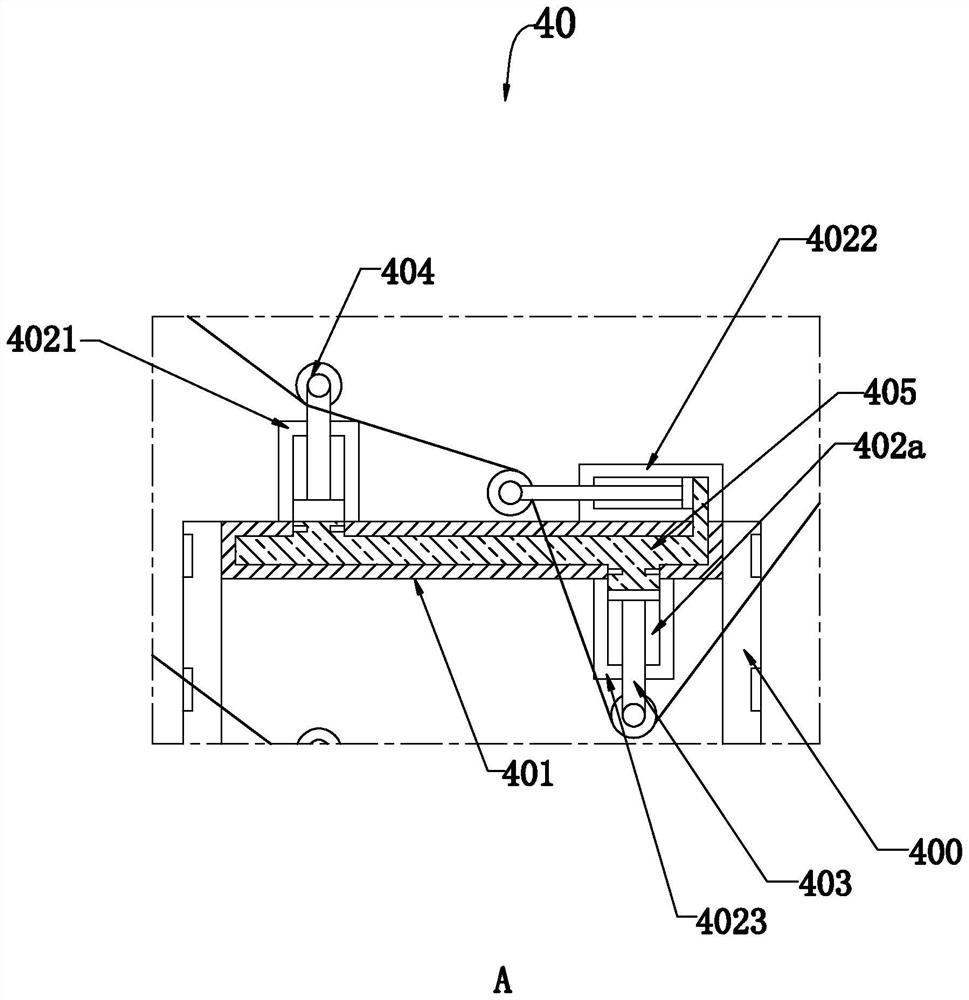

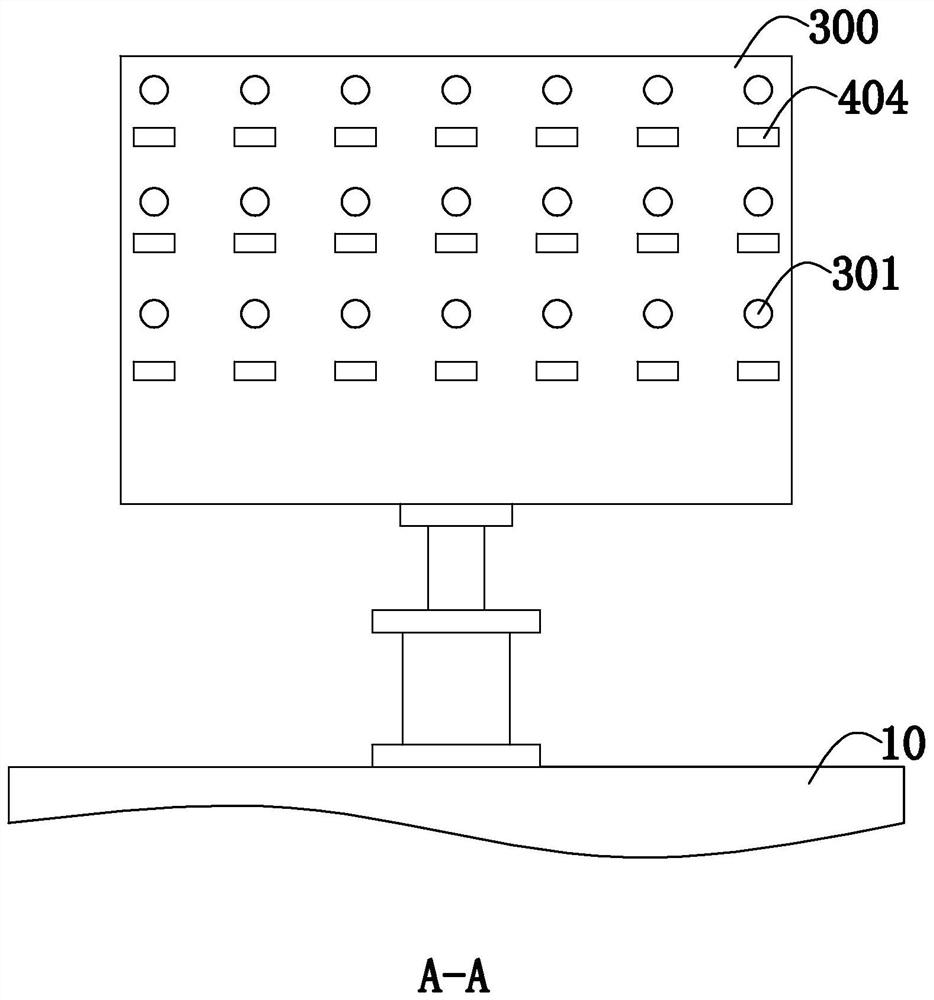

[0052] Such as Figure 1-Figure 4 As shown, the present invention discloses a production system of ultra-high molecular polyethylene fiber socks, including a frame 10 and a knitting module 11 installed on the frame 10. The yarn supply module 20 installed on the frame 10 and the yarn supply cylinder 12, the thread management module 30 arranged between the knitting module 11 and the yarn supply module 20, and the thread management module 30 installed between the yarn management module 30 and the yarn An adjustment unit 40 between the wire supply modules 20 and used to adjust the tension of the yarn 13; The first adjusting body 401 arranged hollowly between the yarn supply modules 20, several second adjusting bodies installed in the first adjusting body 401 and having a buffer chamber 402a communicating with the interior of the first adjusting body 401 , move the telescopic rods 403 in each buffer chamber 402a and the guide pulley 404 installed on the telescopic rods 403 for the...

Embodiment 2

[0068] Embodiment 2, the difference with embodiment 1 is that

[0069] Such as Figure 5-Figure 8 As shown, in the specific embodiment of the present invention, it also includes an adjustment module 50 installed on the frame 10 and used to control the lifting of the board body 300 and to adjust the tension of the yarn 13; wherein, the adjustment module 50 It includes a main frame body 502 installed on the frame 10 through a support rod 500 and has a hinge area 501, at least two first support bodies 504 and second support bodies 504 that are rotatably connected to the inner side wall of the hinge area 501 through a rotating shaft 503. The support body 505, the hinge module 506 connected between any end of the first support body 504 and the plate body 300 and any end of the second support body 505 and the plate body 300, is hinged on the main frame body 502 and The first cylinder 507 used to drive the first support body 504 to rotate around the rotating shaft 503 and lift the b...

Embodiment 3

[0080] Embodiment 3, the difference with embodiment 2 is that

[0081] Such as Figure 9-Figure 14 As shown, in the specific embodiment of the present invention, the wire holes 301 on the board body 300 have several rows and are longitudinally spaced; The fine adjustment module 60 corresponding to and capable of straightening the yarn 13; wherein, the fine adjustment module 60 includes a rod seat 600 which is in contact with the board body 300 and is located above or below each cable hole 301 and is hollowly arranged, and The sliding groove 601 on the top end surface or the bottom end surface of the rod base 600 and communicated with the inside of the rod base 600, the drive shaft 603 arranged inside the rod base 600 and driven by the plc motor 602, at least one is provided on the rod base 600 The limit rib 604 on the drive shaft 603 and extending along the drive shaft 603, several transmission chambers 6050 fitted on the drive shaft 603 and adapted to the drive shaft 603 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com