Fabricated culvert gate for water conservancy project

A water conservancy project and assembled technology, which is applied in the field of culvert gates, can solve problems such as easy retention of debris, inconvenient gate bottom wall close fit, unfavorable gate water storage work, etc., to achieve the effect of enhancing sealing and reducing the probability of seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

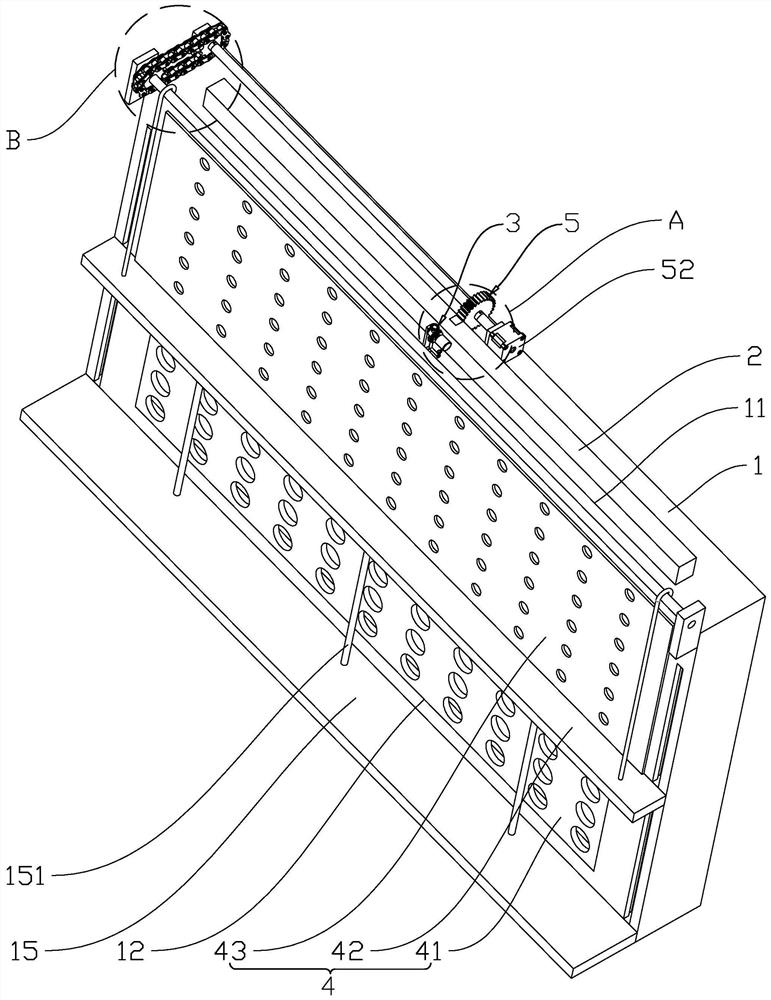

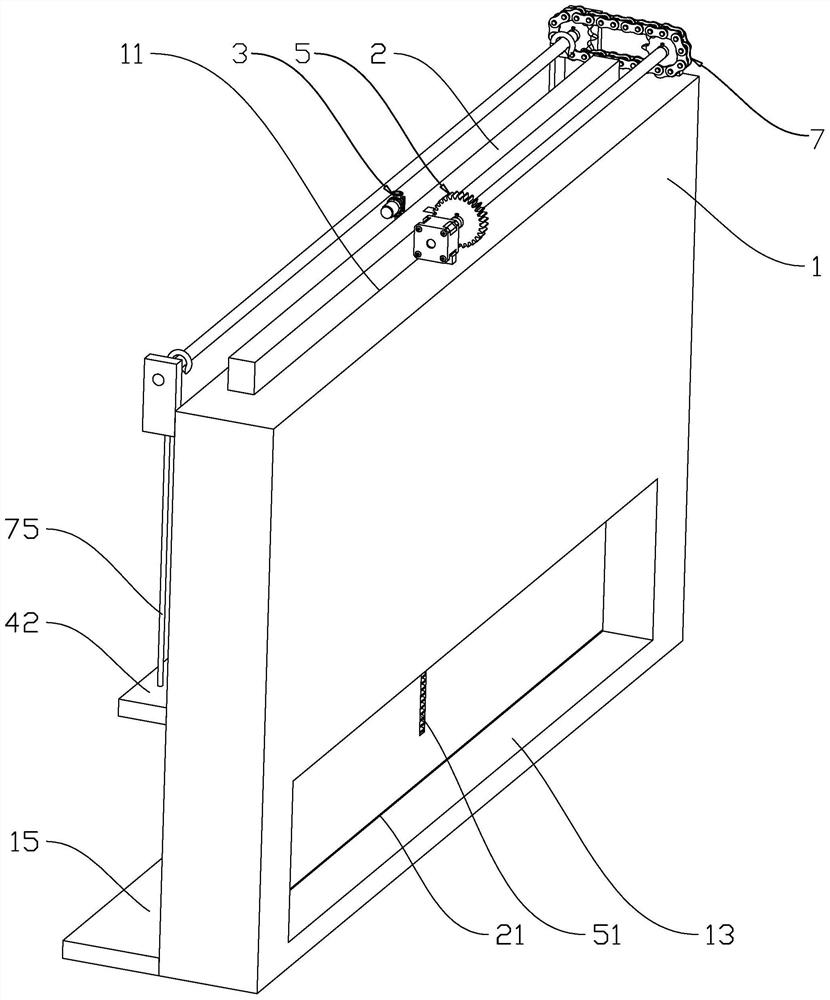

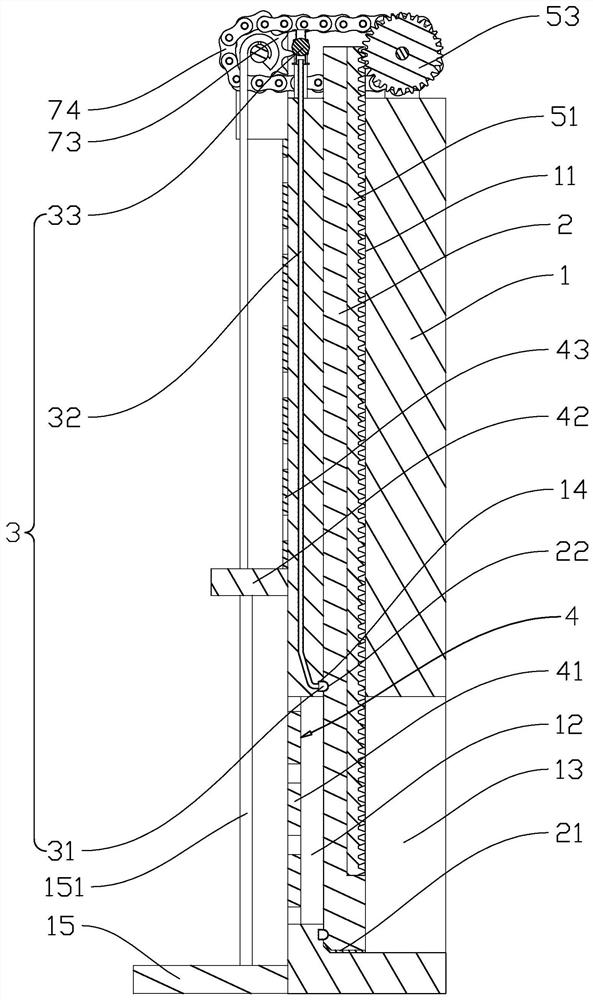

[0033] The following is attached Figure 1-5 The application is described in further detail.

[0034] The embodiment of the present application discloses a prefabricated culvert gate for water conservancy projects. refer to figure 1 The assembled culvert for water conservancy projects includes a gate plate 1, a water retaining plate 2, a sealing assembly 3, a filter assembly 4, and a driving assembly 5. The gate plate 1 is a rectangular steel plate arranged vertically, and the length direction of the gate plate 1 is perpendicular to the water flow direction. , and the side walls on both sides of the gate plate 1 are respectively fixed to the side walls on both sides of the river channel. combine figure 2 As shown, the upper surface of the gate plate 1 is provided with a first installation groove 11, and the side wall of the gate plate 1 close to the upstream side of the water flow is provided with a first drainage through hole 12 communicating with the first installation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com