Construction method of H-shaped steel column installation connector operation platform

A technology for operating platforms and construction methods, applied in the direction of building structure support, building structure support, scaffolding accessories, etc., can solve the problems of reducing the service life of H-shaped steel columns, changing the mechanical properties of steel materials, and destroying low-alloy steel materials. The effects of reducing safety hazards, increasing service life, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] Figure 1-Figure 7 It is a specific embodiment of the present invention. The specific implementation is as follows:

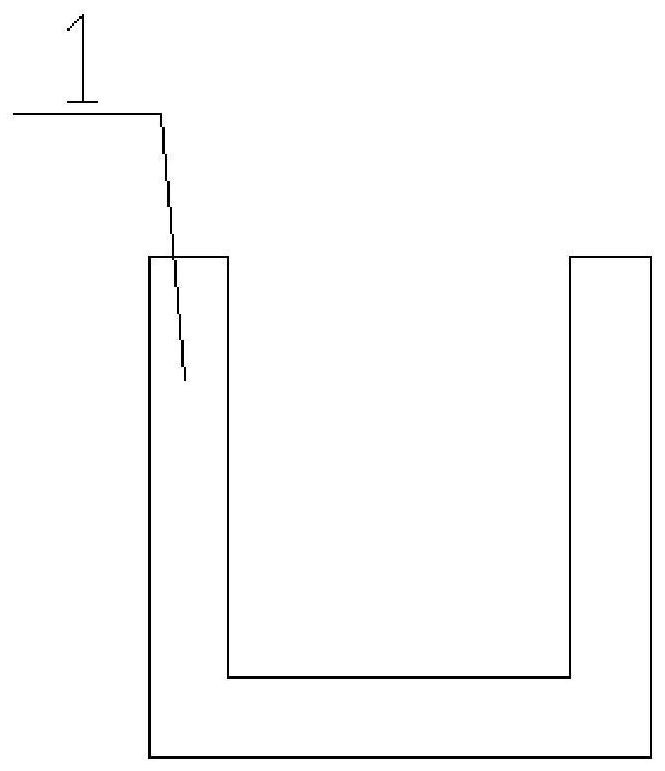

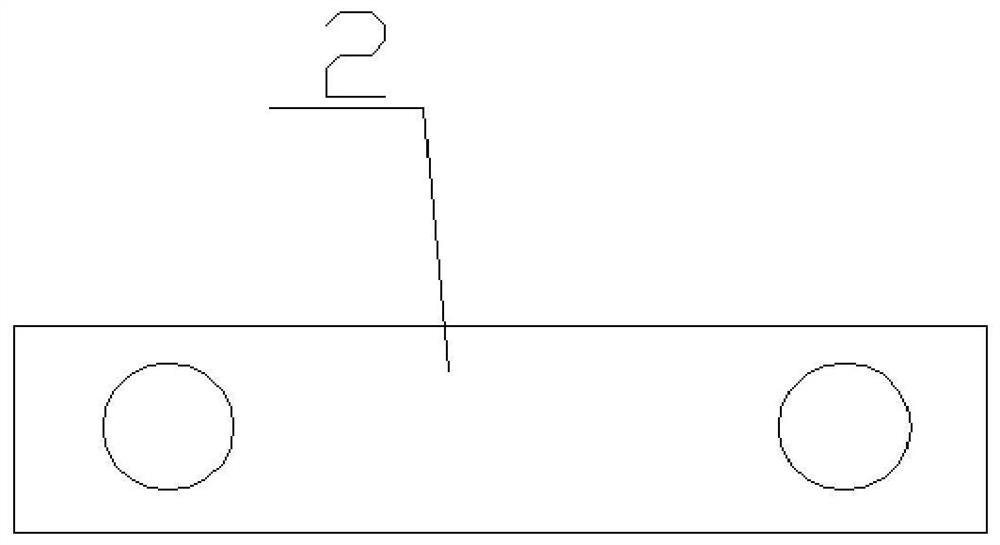

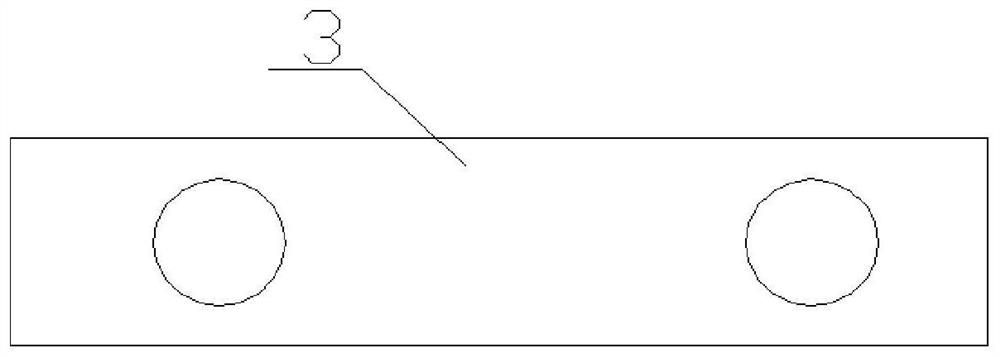

[0020] The first step is to process the U-shaped clamp 1, the web connecting plate 2, and the wing plate connecting plate 3 according to the cross-sectional size of the steel column 4;

[0021] In the second step, the U-shaped card 1 is used to fix the inner side of the flange plate of the H-shaped steel column 4 through the screw 5;

[0022] The third step is to fix the web connecting plate 2 and the bottom surface of the U-shaped card 1 by screws 5;

[0023] The fourth step is to fix the wing plate connecting plate 3 and the outer surface of the U-shaped card 1 by screws 5;

[0024] In the fifth step, after all the inspection screws 5 are tightened, the operating platform corbel 6 is welded to the web connection plate 2 and the wing plate connection plate 3 of the U-shaped card 1 .

[0025] In the frame construction of the main steel-making worksho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com