A kind of mesoporous metal-organic framework multi-site catalyst and its preparation method and application

A metal-organic framework and metal-organic technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve high production costs, difficulty in catalyst recovery, high energy consumption of reactions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, Synthesis of Metal Organic Framework (PCN-222(Co) or PCN-224(Co)).

[0034] Synthesis of PCN-222(Co): Dissolve benzoic acid (1.25 g) and zirconium oxychloride (50 mg) in 10 mLDEF, heat at 100 °C for 1 hour, and phenylcobalt porphyrin carboxylate (50 mg) in the above solution, ultrasonically dissolved, heated at 120 °C for 12 h, and washed with DMF and acetone to obtain 50 mg of purple-red solid. Yield 50%.

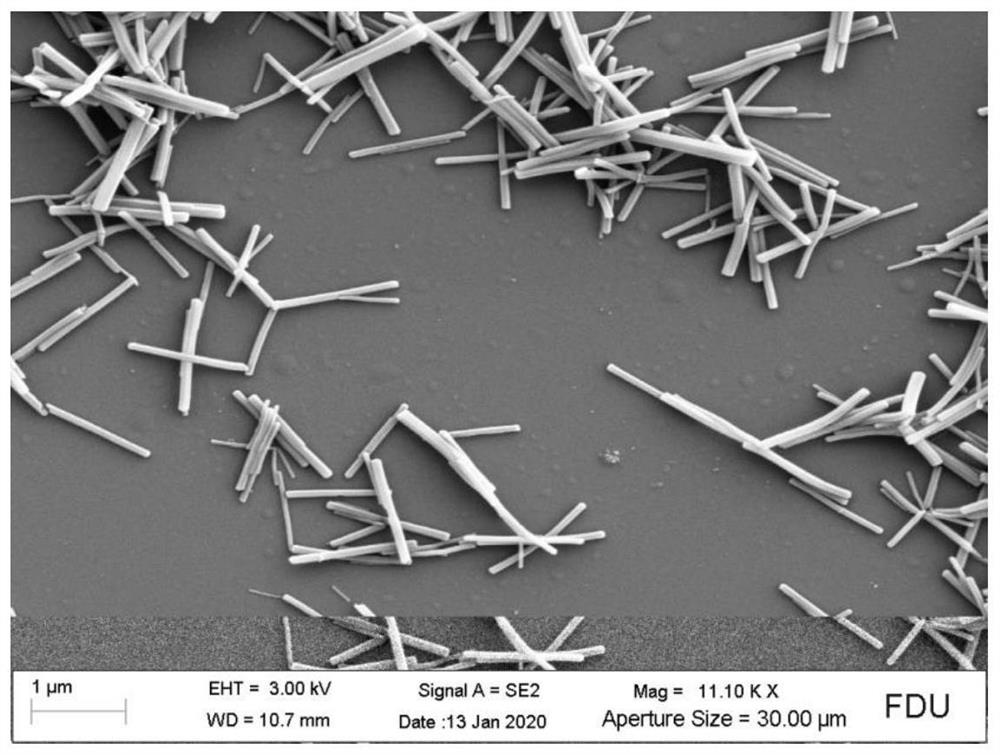

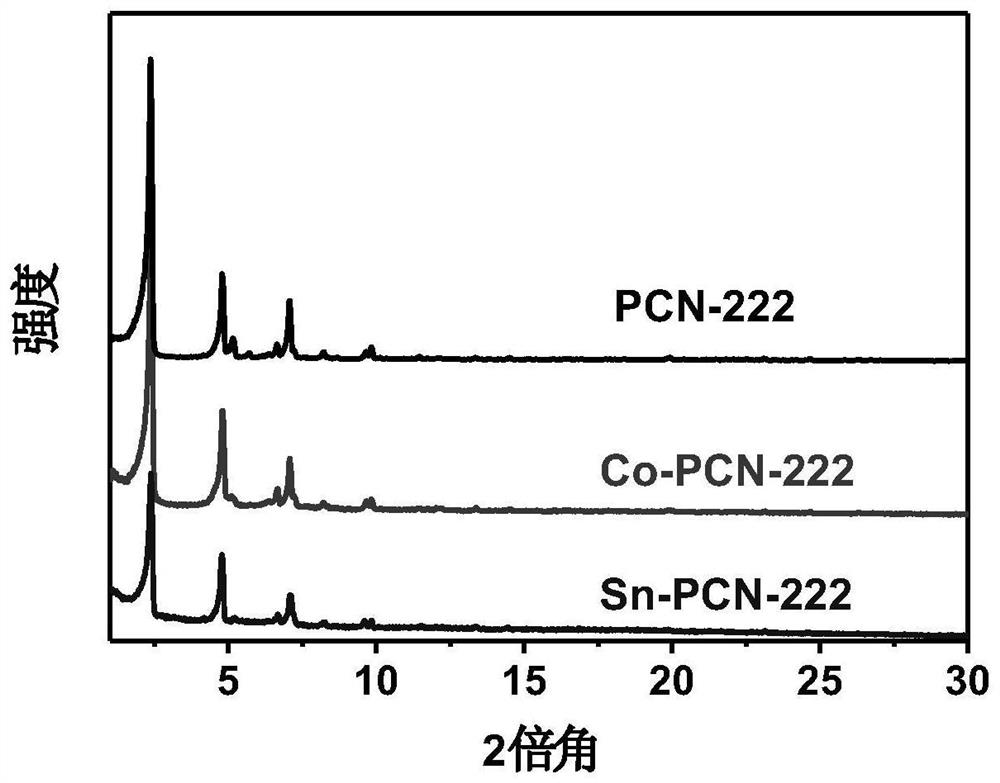

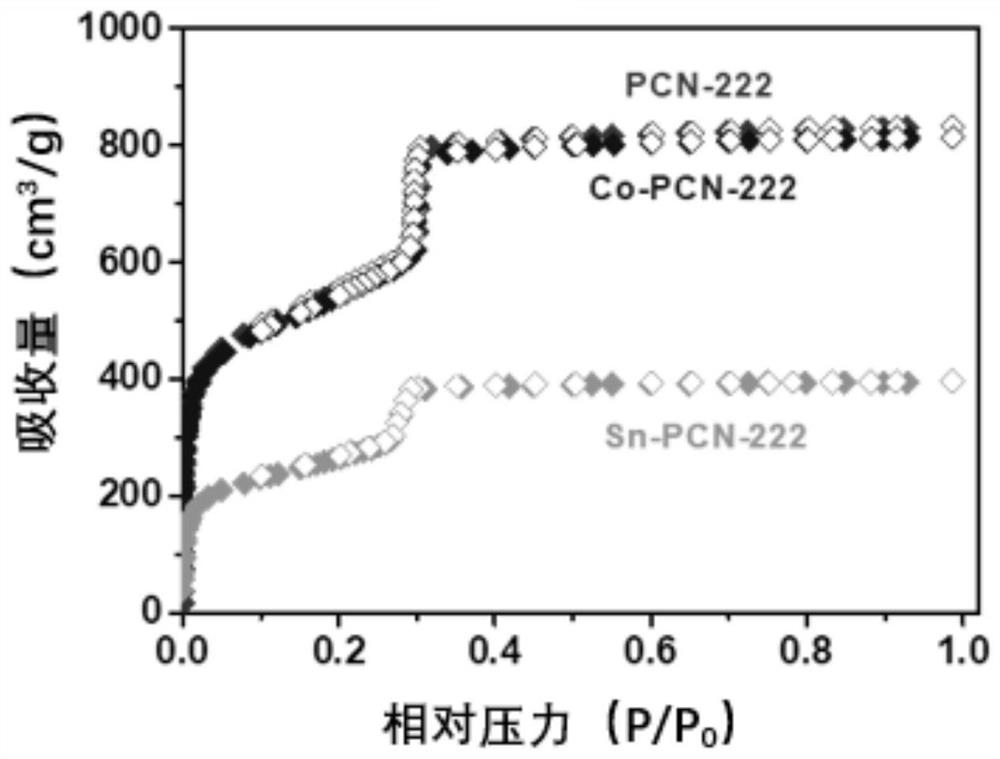

[0035] like figure 1 As shown, the scanning electron microscope (SEM) images of the as-prepared samples showed that the microscopic morphology of PCN-222(Co) was rod-like micron-sized crystals. The crystal structure of PCN-222(Co) ( figure 2) was verified by X-ray powder diffraction pattern (PXRD). N2 adsorption data ( image 3 ) shows that PCN-222(Co) is a mesoporous material with a pore size of 3.6 nm.

[0036] Synthesis of PCN-224(Co): Dissolve benzoic acid (1.5 g) and zirconium oxychloride (50 mg) in 10 mL of DMF, heat at 100 °C for 1 hour, and...

Embodiment 2

[0038] Example 2, Synthesis of Metal Organic Framework (PCN-222(Fe) or PCN-224(Fe)).

[0039] Synthesis of PCN-222(Fe): Dissolve benzoic acid (1.25 g) and zirconium oxychloride (50 mg) in 10 mLDEF, heat at 100 °C for 1 hour, and carboxylic acid phenyliron porphyrin (50 mg) in the above solution, ultrasonically dissolved, heated at 120 °C for 12 h, and washed with DMF and acetone to obtain 50 mg of a brown solid. Yield 50%.

[0040] As shown in the figure, the scanning electron microscope (SEM) images of the as-prepared samples showed that the microscopic morphology of PCN-222(Fe) was rod-like micron-scale crystals. The crystal structure of PCN-222(Fe) ( Image 6 ).

[0041] Synthesis of PCN-224(Fe): Dissolve benzoic acid (1.5 g) and zirconium oxychloride (50 mg) in 10 mL of DMF, heat at 100 °C for 1 hour, and carboxylic acid phenyliron porphyrin (25 mg) in the above solution, ultrasonically dissolved, heated at 120 °C for 12 h, and washed with DMF and acetone to obtain 40 ...

Embodiment 3

[0043] Example 3, Synthesis of Metal Organic Framework (PCN-222(Ni) or PCN-224(Ni)).

[0044] Synthesis of PCN-224(Ni): Dissolve benzoic acid (1.5 g) and zirconium oxychloride (50 mg) in 10 mL of DMF, heat at 100 °C for 1 hour, and phenylnickel porphyrin carboxylate (25 mg) in the above solution, ultrasonically dissolved, heated at 120 °C for 12 h, washed with DMF and acetone, and 40 mg of red solid was obtained. Yield 53%.

[0045] As shown in the figure, the scanning electron microscope (SEM) images of the as-prepared samples showed that the microscopic morphology of PCN-224(Ni) was micron-scale cubic crystals. The crystal structure of PCN-224(Ni) ( Figure 8 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com