A method for obtaining thickness distribution of asymmetrical rolling gap exit of four-high rolling mill

An asymmetrical rolling and exit thickness technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of ignoring the influence and inconsistent calculation results, and achieve the effects of reduced calculation amount, less simplified conditions and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] For a better understanding of the present invention, the present invention will be further described below with reference to specific embodiments.

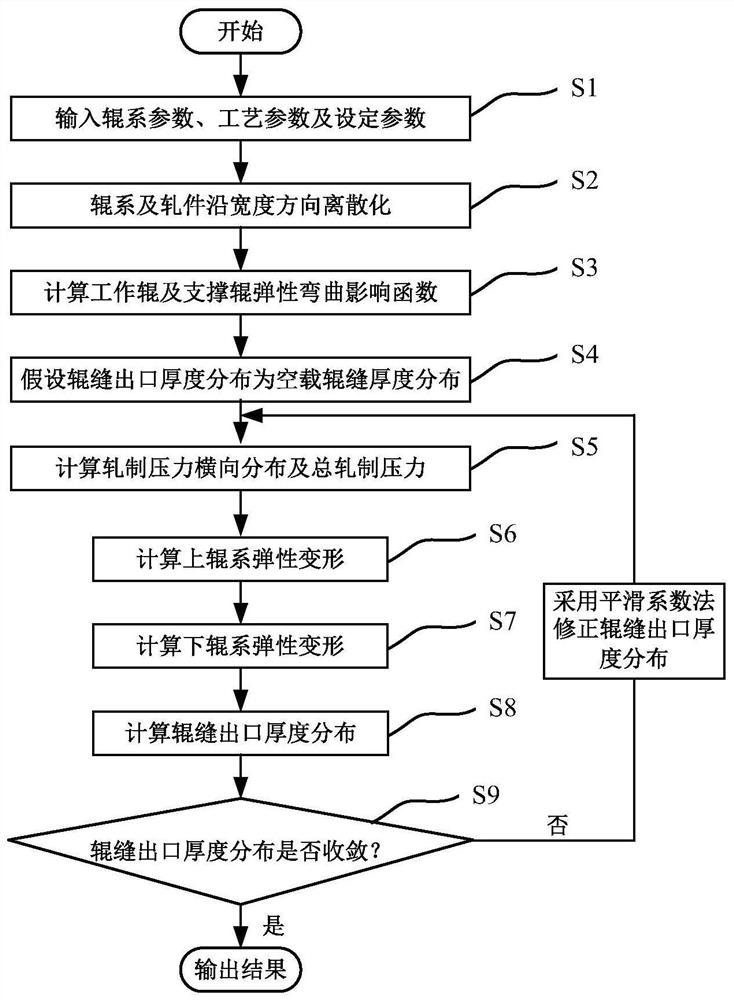

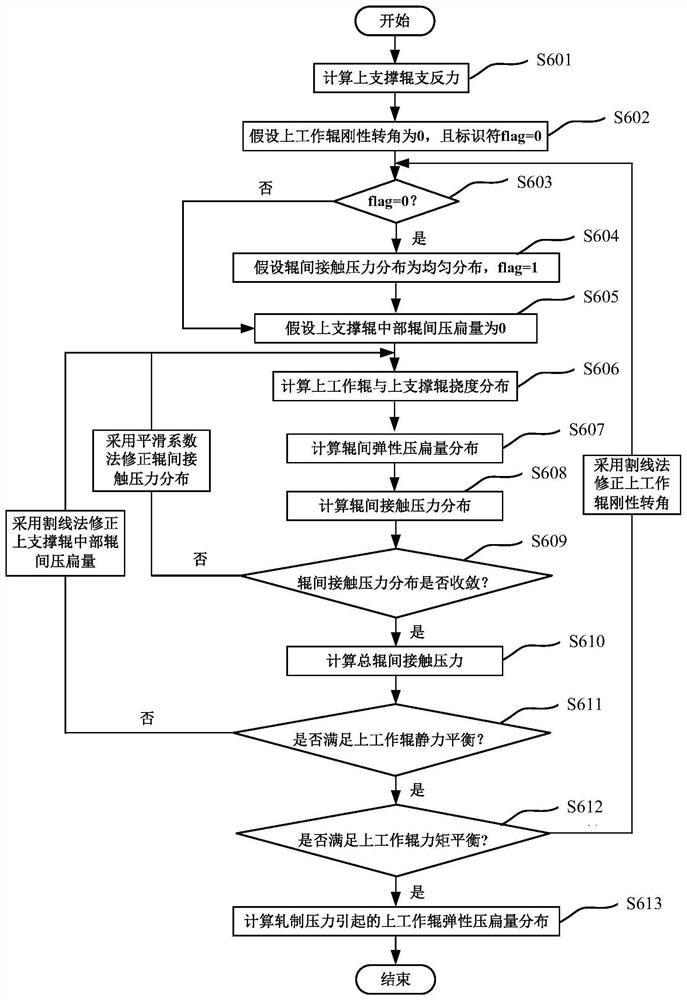

[0088] like figure 1 The shown method for obtaining the thickness distribution of the asymmetrical rolling gap exit of a four-high rolling mill includes the following steps:

[0089] S1. Obtain roll system parameters, process parameters and setting parameters.

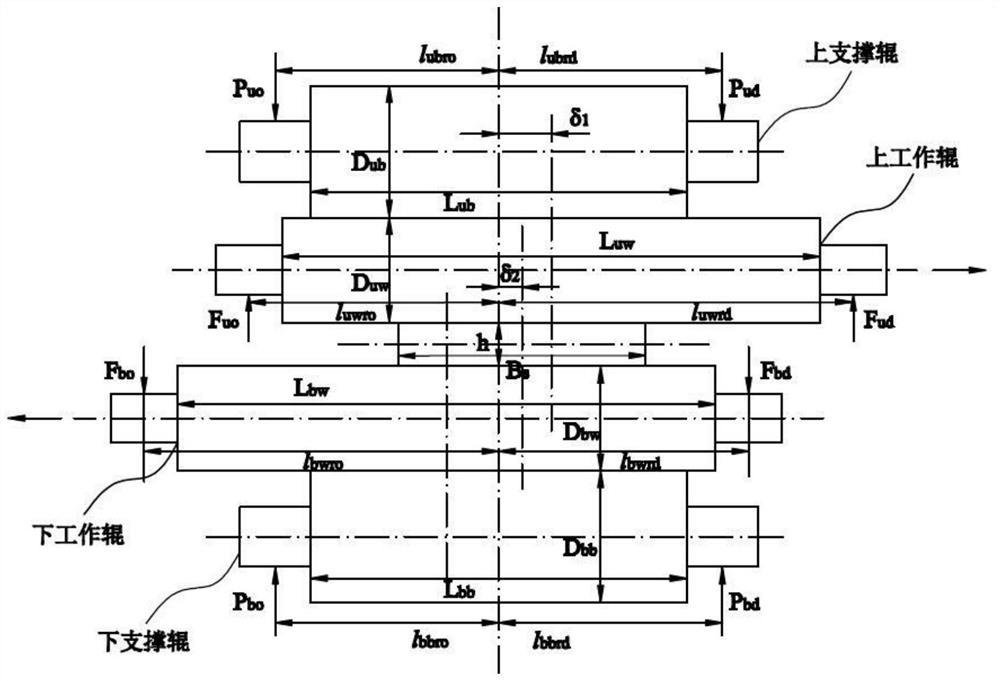

[0090] like figure 2 As shown, the roll parameters include the nominal diameter D of the upper and lower work rolls uw , D bw , roll type D uw (x), D bw (x), roll body width L uw , L bw and the distance l from the action point of the bending roll force to the center of the frame uwro , l uwrd , lbwro , l bwrd ;Nominal diameter D of the upper and lower backup rollers ub , D bb , roll type D ub (x), D bb (x), roll body width L ub , L bb And the distance l from the reaction point of the bearing support to the center of the frame ubr0 , l ubrd , l bb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com