Heat shield forming die structure

A technology for forming molds and heat shields, which is applied in the field of heat shield forming mold structures, can solve problems such as troublesome, laborious, and heat shield forming molds that cannot be used for stamping stretched plates, and achieves the effect of convenient stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

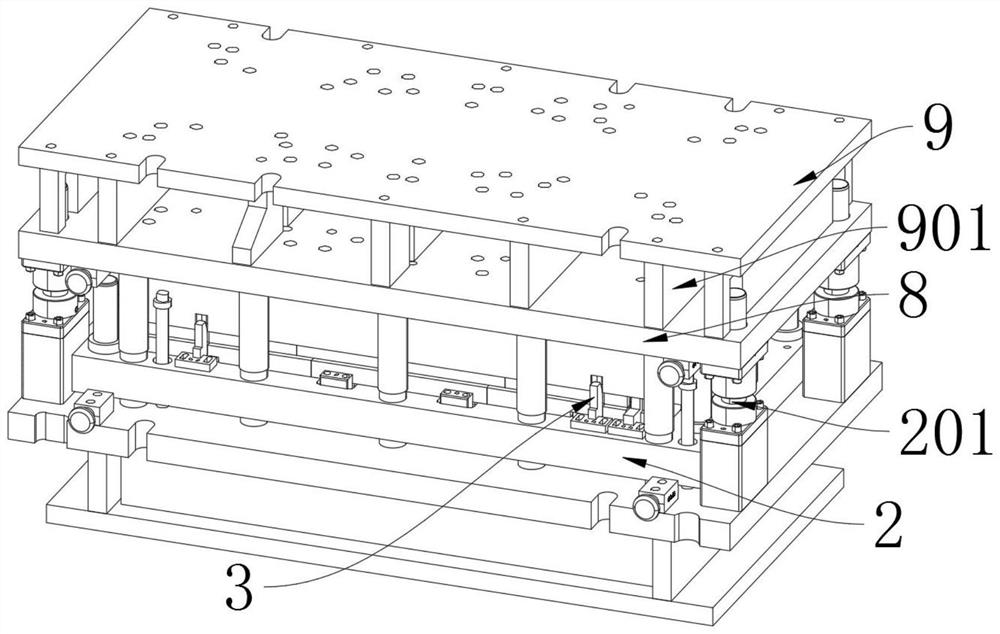

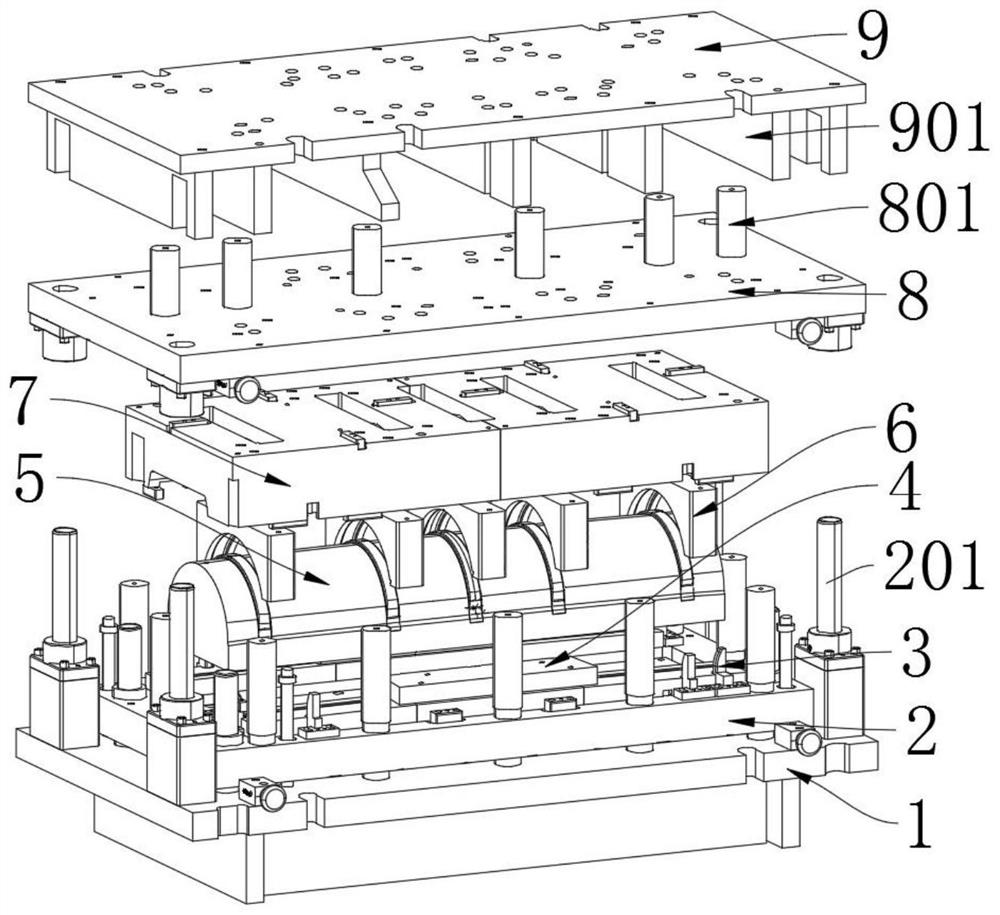

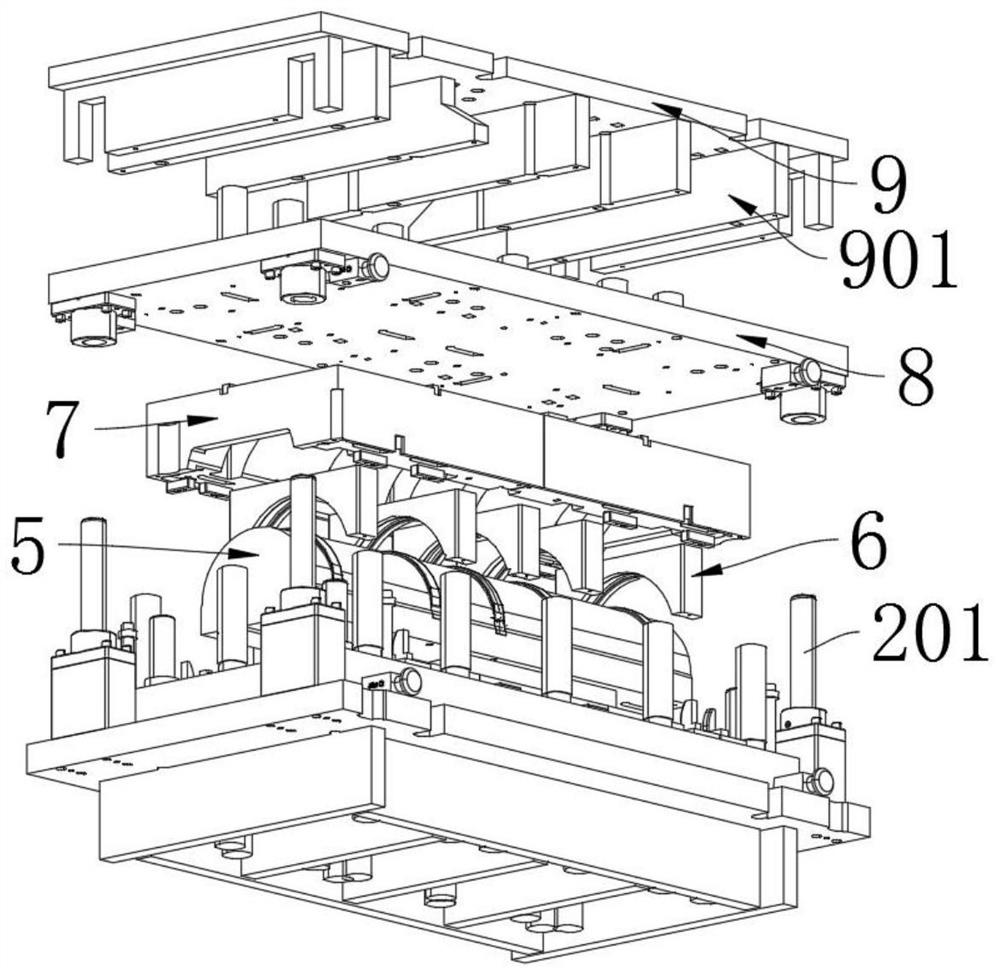

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The invention provides a heat shield forming mold structure, which includes a base 1; a tray 2 is fixed on the base 1 by bolts, and a group of circular support rods are installed on the tray 2, and threaded holes are provided on the support rods; There is a set of sliding blocks 4 with threaded holes, and six sets of pipe positions 3 are installed on the tray 2, and a lower mold shape 5 is clamped on the tray 2; a stamping block 6 is clamped above the lower mold shape 5, and the stamping The block 6 is fixed on the upper mold shape 7 by bolts; the upper mold shape 7 is fixed with a connecting plate 8 by bolts, and the connecting plate 8 includes a connecting column 801, and the connecting column 801 is fixed with a top plate 9 by bolts; the top plate 9 includes There are supporting blocks 901, and two rectangular slots are opened on the supporting blocks 901 at the left and right ends;

[0029] Wherein, the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com